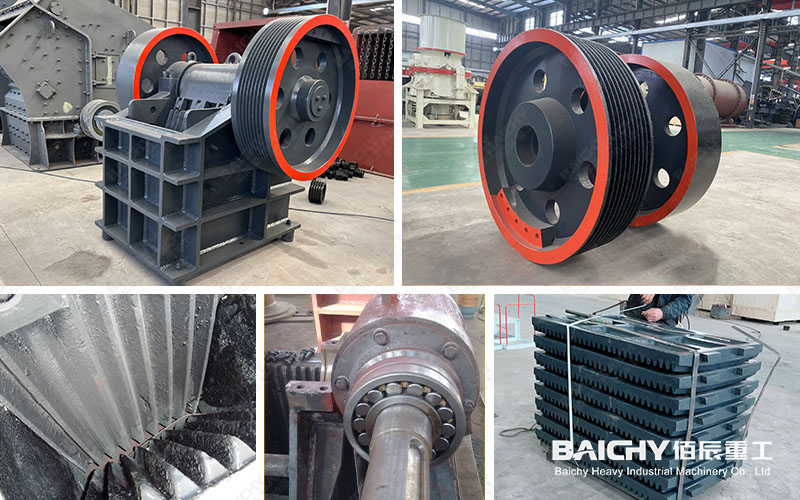

PE 400x600 Jaw Crusher

In the field of mining crushing, selecting the right primary crushing equipment is the cornerstone of the efficient and stable operation of the entire production line. Among the many specifications of jaw crushers, the PE400X600 (or 16x24 jaw crusher) is undoubtedly a long-standing star product.

As a manufacturer with 20 years of professional experience in mining crushing equipment, we will take you through an in-depth look at why this equipment has become the ideal choice for many small and medium-sized stone quarries, construction waste treatment plants, and mining projects worldwide.

I. Classic Specifications, Perfect Balance of Performance and Economy

The PE400X600's name comes from its feed opening size: 400 mm x 600 mm (approximately 16 inches x 24 inches). This size has been proven in the market over a long period, achieving an excellent balance between processing capacity, equipment investment, and operating costs.

• Feed Size: The maximum feed size is typically 340 mm, easily handling raw ore and boulders from dump trucks or excavators.

• Processing Capacity: With adjustments to different discharge ports, its hourly output can be stably maintained between 16-60 tons. This output range perfectly matches the needs of small to medium-sized stone production lines with an hourly output of 50-150 tons.

• Motor Power: Typically equipped with a 30-37kW motor, ensuring strong crushing force while effectively controlling energy consumption, thus reducing long-term operating costs for users.

Detailed diagram of PE400x600 jaw crusher parts

II. Robust Structure and Scientific Design Ensure Long-Term Stable Operation

Based on 20 years of design and manufacturing experience, we have continuously optimized the structure of the PE400X600, with its reliability reflected in every detail:

• Heavy-duty Frame: Welded from high-quality steel plates, the robust structure can withstand enormous crushing impact forces, ensuring long-term stability of the equipment under harsh working conditions.

• Moving Jaw and Bearings: The core component of the moving jaw is cast from high-manganese steel, offering high wear resistance. Equipped with large, heavy-duty roller bearings, its load-bearing capacity far exceeds that of ordinary bearings, resulting in a longer service life.

• Unique Crushing Chamber Design: The optimized V-shaped chamber design eliminates dead zones, effectively improving feeding capacity and ensuring smooth material flow within the chamber, thus increasing crushing efficiency and output.

• Double-Action Toggle Plate: Not only does it transmit crushing force, but it also acts as an overload protection device. When uncrushable materials (such as iron blocks) enter the chamber, the toggle plate breaks first, protecting other core components of the main unit from damage and significantly reducing losses from unexpected downtime.

III. Wide Range of Applications, Multi-Functional Machine

The PE400X600 is highly adaptable, truly a jack-of-all-trades:

• Crushing of high-hardness stones such as granite and basalt: Its powerful extrusion force is sufficient to handle high-hardness materials, providing qualified raw materials for subsequent medium and fine crushing.

• Crushing of medium-hardness stones such as limestone and bluestone: Under these conditions, equipment wear is reduced, efficiency and output are higher, and economic benefits are significant.

• Construction Waste Recycling: As primary crushing, it breaks large pieces of concrete, bricks, etc., into smaller particles, facilitating subsequent sorting and reprocessing.

• Primary Crushing in Mining: Suitable for the initial crushing of raw ore from small-scale metal and non-metal mines.

IV. Additional Advantages of Choosing the PE400X600

As an experienced manufacturer, we understand that service and support are just as important as the equipment itself. By choosing our PE400X600, you will also gain:

• Easy Maintenance: The structural design prioritizes ease of maintenance, allowing for quick replacement of wear parts (such as jaw plates), reducing downtime.

• High Parts Universality: As a globally standardized product, its wear parts are readily available in the market, making procurement convenient, and costs relatively transparent and controllable.

• Extensive Supporting Experience: We can configure the most suitable feeder, vibrating screen, and conveyor equipment according to your specific material and production needs, providing a one-stop solution.

The PE400X600 (16x24) jaw crusher, with its classic specifications, robust structure, stable performance, and wide range of applications, proves to be a highly cost-effective investment. It may not be the largest or most advanced, but it is undoubtedly a time-tested and most reliable primary crushing partner. For investors seeking long-term, stable returns, choosing such a reliable machine is undoubtedly the first step towards success.