Should You Choose a 24"x36" or a PE600x900 Jaw Crusher In The Philippines?

In the booming construction and infrastructure development wave in the Philippines, efficient and reliable primary crushing equipment is the cornerstone of successful mining and quarrying operations. Among these, jaw crushers, with their robust structure, simple principles, and high processing capacity, are the absolute workhorses of primary crushing.

For many Filipino customers, the 24"x36" jaw crusher and the PE600x900 jaw crusher are two of the most common and attractive options. As a mining crushing equipment manufacturer with 20 years of experience, we will delve into these two models to help you make informed investment decisions.

| Key Words | 24x36 Jaw Crusher |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤500mm |

| Motor Power | 55kw |

| Capacity | 90-180t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

In-depth Analysis: Two Specifications, One Standard

First, it's necessary to clarify a common confusion: the 24"x36" jaw crusher uses imperial inches as its unit of measurement, referring to the feed opening size (24 inches wide x 36 inches long). The PE600x900 jaw crusher, on the other hand, uses the internationally accepted metric millimeter unit, corresponding to a feed opening size of 600 mm x 900 mm. Through unit conversion (1 inch ≈ 25.4 mm), we can conclude that: 24"x36" ≈ 610mm x 915mm. Therefore, the PE600x900 and the 24"x36" are essentially the same class of jaw crusher with very similar dimensions, both belonging to the medium-sized jaw crusher category, and are the most popular models for processing medium-sized rocks (such as river pebbles, granite, and basalt).

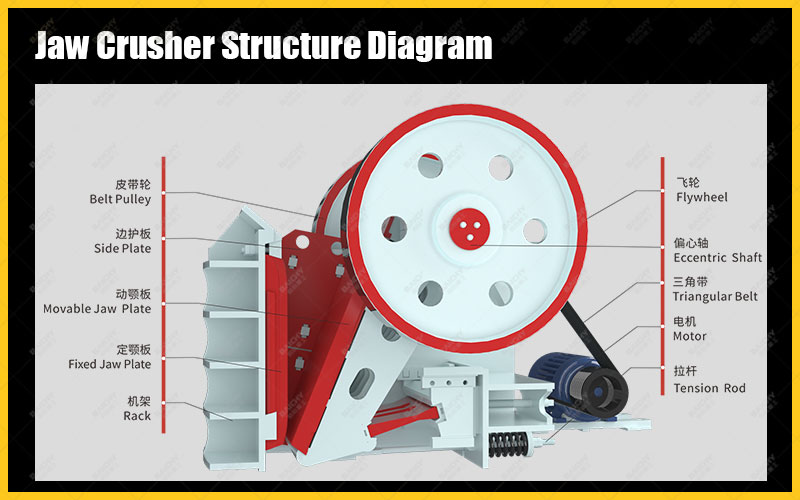

PE jaw crusher structure diagram

Equipment Overview and Core Advantages

Whether called the 24"x36" or the PE600x900, this equipment has become a favorite in the Philippine market due to its excellent design and performance:

• Strong processing capacity: The hourly output range is typically between 100-250 tons, depending on the material properties and discharge opening settings, meeting the needs of most medium-sized production lines.

• Suitable feed size: The maximum feed size is approximately 500mm, easily handling raw ore from dump trucks or loaders.

• Robust and Durable Structure: Utilizing a high-strength steel plate welded frame and heavy-duty eccentric shaft bearings, ensuring long-term stable operation under the harsh, high-humidity, and high-load working conditions in the Philippines.

• Easy Maintenance: The jaw crusher has a simple structure, and wear parts (such as jaw plates) are easy to replace, reducing long-term maintenance costs and downtime.

As a manufacturer with 20 years of experience, we have continuously optimized our classic models, for example, by using a deeper crushing chamber to increase output and improve product particle shape, optimizing the moving jaw's trajectory to reduce liner wear, and providing hydraulic discharge opening adjustment and tramp iron protection devices, further enhancing the equipment's modernity and safety.

Stationary crushing production line

Actual Application Case Study

One of our PE600x900 jaw crushers has been operating stably for over 5 years in a basalt quarry on Luzon Island in the Philippines. This customer produces high-quality aggregates to supply local highway projects. The equipment operates 12 hours a day, processing high-hardness basalt, with an average output of approximately 180 tons per hour. The customer particularly appreciates its "extremely low failure rate under continuous high-intensity operation" and "our local workers can independently complete daily maintenance and jaw plate replacement after simple training," which greatly guarantees the project's supply schedule.

Related Equipment Recommendations

A complete stone production line involves more than just a jaw crusher. Depending on the specifications of your final product (e.g., 0-5mm, 5-10mm, 10-20mm, etc.), we usually recommend the following supporting equipment:

1. Secondary crushing equipment: such as a cone crusher (suitable for high-hardness rocks) or an impact crusher (suitable for medium-to-low hardness rocks, with better particle shape).

2. Screening equipment: multi-layer vibrating screen, used to classify the crushed material into different product specifications.

3. Feeding and conveying system: vibrating feeder and belt conveyor, forming a continuous and efficient production line.

We can provide complete solutions and equipment supply, from single machines to entire production lines.

Frequently Asked Questions (FAQ)

Q1: For the Philippine market, is it better to use the 24"x36" or PE600x900 designation?

A1: There is essentially no difference between the devices themselves. The key is to clearly define the technical parameters with the supplier. It's more important to choose a manufacturer with extensive export experience, who can provide clear English drawings, international standard spare parts lists, and localized after-sales support.

Q2: What are the power consumption and foundation requirements for this equipment?

A2: The main motor power is typically between 55-75kW. The equipment weighs approximately 15-20 tons and requires a sturdy concrete foundation. Our technical team will provide detailed foundation drawings and installation instructions.

Q3: What is the lifespan of the wear parts (jaw plates)?

A3: This directly depends on the abrasiveness of the crushed material. For basalt and andesite commonly found in the Philippines, high-manganese steel jaw plates typically last 3-6 months under normal use. We offer jaw plates made of various materials (such as ultra-high manganese steel and composite metals) to suit different working conditions and optimize your cost per ton.

Q4: Can you provide local after-sales support?

A4: Yes. Based on 20 years of global operating experience, we have reliable service agents and spare parts warehouses in the Philippines with whom we have long-term partnerships. We can provide timely installation guidance, operation training, regular inspections, and spare parts supply support to ensure your production line continues to generate profits.

Choosing a reliable 24"x36" or PE600x900 jaw crusher is a solid first step towards the success of your stone project in the Philippines. Instead of focusing on the name, it's better to focus on the manufacturer's strength, technical expertise, and long-term service commitment. We look forward to becoming your trusted partner, leveraging our twenty years of professional experience to explore the unlimited possibilities of the Philippine market together.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.