PE600×900 Jaw Crusher: Working Principle and Advantages

As a manufacturer with twenty years of experience in the field of mining crushing equipment, we understand that a reliable and efficient primary crushing machine is the cornerstone of the entire production line. Among numerous types of equipment, the jaw crusher, with its simple structure, reliable operation, and strong adaptability, is hailed as the king of primary crushing. The PE600x900 jaw crusher, in particular, is a classic model that has stood the test of time and remains highly favored by the market. This article will delve into the working principle of the jaw crusher and, combined with our years of manufacturing and application experience, provide you with a comprehensive understanding of the unique advantages of the PE600x990 jaw crusher.

| Key Words | PE600×900 Jaw Crusher |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤500mm |

| Motor Power | 55kw |

| Capacity | 90-180t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Jaw Crusher Working Principle: The Art of Crushing Simulating Animal Chewing

The core working principle of the jaw crusher can be summarized as the periodic reciprocating motion of the movable jaw relative to the fixed jaw, thereby compressing, splitting, and frictionally crushing the material.

Its working process mainly consists of two stages:

1. Feeding and Pre-crushing Stage: The material falls from the feeding port at the top of the crusher into the crushing chamber formed by the movable and fixed jaws. When the movable jaw swings towards the fixed jaw plate, the material is subjected to compression and splitting, and begins to be crushed.

2. Crushing and Discharge Stage: As the movable jaw continues to advance, the angle between the two jaw plates decreases, and the crushing force on the material increases sharply. When the force exceeds the compressive strength of the material itself, the material is crushed. The crushed material, under its own gravity, is discharged from the bottom of the crushing chamber (discharge port) as the movable jaw moves away (recedes). Each reciprocating motion of the movable jaw completes one crushing cycle.

This seemingly simple process, its efficiency and stability depend on precise calculations and manufacturing processes of power transmission, toggle plate angle, and cavity design – a testament to our twenty years of technological accumulation.

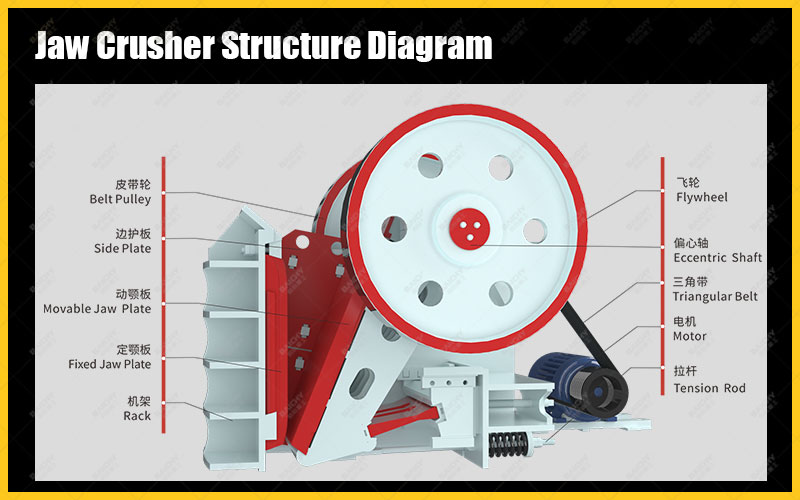

PE jaw crusher structure diagram

PE600×900 Jaw Crusher

The PE600x900 jaw crusher is one of the most common primary crushing equipment models in medium-sized production lines. Its model naming convention is straightforward: PE represents jaw crusher, 600 indicates a feed opening width of 600mm, and 900 indicates a feed opening length of 900mm. This means the machine can handle large rocks with a maximum feed size of approximately 500mm, making it an ideal entry-level and mid-range equipment for processing medium to high-hardness materials such as granite, basalt, and river pebbles.

Core Advantages of the PE600×900 Jaw Crusher

Based on the classic jaw crusher working principle, the PE600x900 model, through years of optimization, exhibits the following outstanding advantages:

• Robust Structure and High Reliability: Utilizing a high-quality cast steel frame, heavy-duty eccentric shaft, and high-quality bearings, it ensures stable operation under heavy load impacts and has an extremely low failure rate.

• Excellent Crushing Efficiency: The feed size and crushing chamber design have been optimized to achieve higher processing capacity at the same power, with an hourly output ranging from 90 to 180 tons, flexibly adapting to different production needs.

• Convenient Maintenance and Repair: All components are designed for easy accessibility. In particular, the toggle plate not only acts as a safety pin, breaking in case of overload to protect the main machine, but is also very easy to replace, significantly reducing downtime.

• Wide Adaptability: By adjusting the wedge-shaped discharge opening adjustment device at the rear, the discharge particle size can be easily changed to meet the feed requirements of downstream secondary crushing, allowing for multi-purpose use.

• Excellent Cost-Effectiveness: As a technologically mature model with a complete supply chain, it achieves the best balance between purchase cost, operating cost, and maintenance cost, resulting in a very high return on investment.

Stationary crushing production line

Case Study Sharing

Among the many clients we serve, a large aggregate project in East China is a typical example. This project uses granite as raw material and requires a primary crushing capacity of 150 tons per hour. We configured this PE600x900 jaw crusher as the primary crusher for them.

Operating Results:

• Feed: Granite raw material with a particle size of 0-500mm.

• Output: The discharge opening was adjusted to approximately 100mm, producing a primary product with a particle size of 0-100mm.

• Performance: The equipment has been running continuously and stably for over 2 years without major failures, fully meeting the stable material supply requirements of the subsequent secondary crushing and sand making processes. Customers highly praise its characteristics of handling coarse materials, stable operation, and low operating costs, which perfectly embodies the reliable working principle of the jaw crusher combined with the classic design of the PE600x900.

Related Equipment Recommendations

When configuring a production line, the PE600x900 jaw crusher usually needs to be used in conjunction with the following equipment:

• Feeding equipment: ZSW-380×96 vibrating feeder, which provides uniform and controllable feeding to the crusher, preventing blockages or idling.

• Secondary and fine crushing equipment: Single-cylinder hydraulic cone crusher (such as SC160S) or multi-cylinder hydraulic cone crusher, used for secondary and fine crushing of materials after primary crushing to produce the required aggregate specifications.

• Screening equipment: 2-3 3YK-1860 vibrating screens, forming a closed-loop system to ensure that the finished product particle size meets the requirements.

• Conveying equipment: B800-B1000 series belt conveyors, connecting each process stage.

Frequently Asked Questions (FAQ)

Q1: What is the motor power of the PE600x900 jaw crusher?

A1: It is usually configured with a 6-pole 75kw motor to ensure sufficient torque for crushing hard materials.

Q2: How fine can the output particle size of the equipment be adjusted?

A2: By adjusting the shims, the discharge opening adjustment range is usually between 65-160mm, and the corresponding main product particle size range is approximately 80-200mm. For finer products, subsequent secondary crushing equipment is required.

Q3: What is the wear cycle of the jaw plates?

A3: This is closely related to the hardness and abrasiveness of the crushed material. For hard rocks such as granite and basalt, the service life of a set of high-manganese steel jaw plates is usually 3-6 months. We offer jaw plates of various materials (such as reinforced high-manganese steel, composite alloys, etc.) to adapt to different working conditions and extend service life.

Q4: As a manufacturer, what support can you provide?

A4: We provide one-stop service from site planning, equipment selection, installation guidance, operation training to lifelong maintenance. We maintain a comprehensive inventory of spare parts to ensure your equipment operates continuously and efficiently.

We hope this detailed explanation will provide you with a deeper and more professional understanding of the working principle of jaw crushers and the classic PE600x900 jaw crusher. Choosing a reliable piece of equipment is like choosing a solid pioneer for your production line. For any specific needs or technical questions, please feel free to contact our professional team with twenty years of experience.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.