PE16"X24" Jaw Crusher | 400x600 Jaw Crusher Price and Advantages

As a mining crushing equipment manufacturer with 20 years of extensive experience, we understand the importance of reliable and efficient primary crushing equipment for the entire production line. Among numerous jaw crusher models, the PE16x24 jaw crusher (i.e., a jaw crusher with a feed opening size of 400x600mm) is considered the gold standard and backbone for small and medium-sized crushing plants. It perfectly balances processing capacity, equipment investment, and operational stability, making it one of the most widely used classic models globally.

| Key Words | PE16"X24" Jaw Crusher |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤340mm |

| Motor Power | 30kw |

| Capacity | 15-60t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

The 16x24 specification directly indicates the size of the crusher's feed opening (16 inches wide x 24 inches long, approximately 400mm x 600mm). This size design is not accidental, but rather the optimal solution derived from engineering practice:

• Wide applicability: Its feed size can easily accommodate most common primary ores, river pebbles, granite, basalt, etc., with a maximum feed size typically around 340mm, making it ideal for the first crushing stage.

• Optimal capacity range: Under standard working conditions, this model typically has a processing capacity of 16-60 tons per hour. This capacity range perfectly matches the actual needs of many small and medium-sized sand and aggregate production lines, construction waste treatment projects, and small and medium-sized mines, avoiding the waste of resources from oversized equipment or the inadequacy of undersized equipment.

• Cost-effective choice: Compared to larger models, it has a smaller footprint, lower infrastructure costs, and relatively economical energy consumption; compared to smaller models, its capacity and stability are significantly improved, resulting in higher long-term overall benefits.

Reliable Performance of a Classic Structure

The PE16x24 jaw crusher adopts the classic double-toggle jaw crusher structure. Its core working principle is to crush materials through the combined action of compression, splitting, and bending caused by the periodic reciprocating motion of the movable jaw relative to the fixed jaw. The main structure includes:

• Robust frame: Made of high-quality steel plates and welded, it undergoes stress relief treatment to ensure long-term stability under heavy load impacts. • High-Chrome Alloy Jaw Plates: Both the movable and stationary jaws are equipped with replaceable, high-wear-resistant jaw plates, offering not only a long service life but also providing the optimal crushing tooth profile.

• Heavy-Duty Eccentric Shaft: The forged and precision-machined eccentric shaft is the core component for power transmission, boasting extremely high load-bearing capacity.

• Adjustable Discharge Opening: The discharge opening size can be easily adjusted using a wedge or shim adjustment device, allowing for precise control of the final product particle size and offering high flexibility.

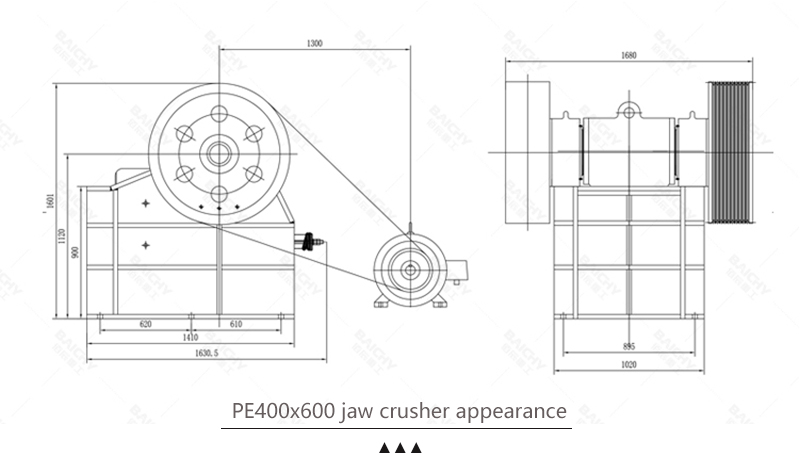

PE400x600 Jaw Crusher Outline Dimensions Diagram

Quality Forged by 20 Years of Manufacturing Experience

Based on our twenty years of technological accumulation and continuous improvement, our PE400x600 jaw crusher boasts the following outstanding advantages:

1. Exceptional Reliability: Core bearings use well-known brands and employ grease or thin oil lubrication systems, ensuring continuous and stable operation under harsh working conditions. The low equipment failure rate is crucial for guaranteeing continuous operation of the production line.

2. High Crushing Performance: The optimized cavity design delivers a higher crushing ratio and capacity. The deeper crushing chamber ensures that the material is fully crushed within the chamber, increasing single-machine output.

3. Lower Operating Costs: Wear parts such as jaw plates use our proprietary high-wear-resistant materials, resulting in a long service life and significantly reducing the cost per ton of crushed material. The overall structure is simple, making maintenance quick and easy.

4. Strong Adaptability: It can handle not only hard and abrasive ores, but also has been specially optimized for adaptability to humid and sticky materials, reducing the risk of clogging.

5. Flexible Power Configuration: It can be matched with 30-37kW motors, and can be driven by either a diesel engine (suitable for mountainous areas without electricity) or an electric motor, meeting perse customer needs.

30-50 tph river pebble crushing production line

Application Cases: The Common Choice of Global Customers

Case Study 1: A Granite Quarry in Southeast Asia

This customer uses one of our PE16X24 jaw crushers as a primary crusher, paired with a cone crusher and a vibrating screen, forming a 50-ton per hour aggregate production line. The equipment has been operating stably for over 5 years, with a stable output particle size of 0-40mm, used for local road construction. The customer reported that the equipment requires almost no attention, only requiring jaw plate replacement once a year, resulting in very low maintenance costs. • Case Study Two: A Construction Waste Recycling Project in China

In this project, our 400x600 jaw crusher is responsible for the primary crushing of concrete blocks and bricks after initial sorting. Its powerful impact resistance and adjustable discharge opening perfectly address the challenges of complex composition and numerous impurities in construction waste, making it a core piece of equipment in this project.

Related Equipment Recommendations

A complete crushing production line involves more than just a jaw crusher. We provide our customers with a one-stop solution:

• Secondary and Fine Crushing Options: We recommend pairing it with a PY spring cone crusher or PF impact crusher for secondary crushing to obtain finer, better-shaped finished products.

• Feeding and Screening: A ZG series vibrating feeder is used at the front end to ensure uniform feeding; a 3YK series circular vibrating screen is used at the back end for efficient classification.

• Conveying System: We provide a complete set of TD belt conveyors to connect all process stages.

Frequently Asked Questions (FAQ)

Q1: What is the maximum feed size of this equipment?

A1: The maximum feed size is approximately 340mm (depending on the material characteristics). We recommend that the longest side of the feed material does not exceed 320mm to achieve optimal crushing results and equipment protection.

Q2: How fine can the output particle size be adjusted?

A2: By adjusting the discharge opening, the discharge opening adjustment range is typically between 40-100mm. Therefore, the main particle size range of the final product is approximately 50-150mm. For finer products, a secondary crushing equipment is required.

Q3: Are the installation and foundation requirements of the equipment complex?

A3: As a medium-sized jaw crusher, its installation requires a professional civil engineering foundation. We will provide detailed foundation drawings and installation instructions with the equipment. For overseas customers, we can send engineers for on-site installation and commissioning guidance.

Q4: What is the lifespan of key wear parts (such as jaw plates)?

A4: This strongly depends on the hardness of the crushed material (Mohs hardness). Taking limestone crushing as an example, the lifespan of a set of jaw plates can usually reach 6-12 months or even longer. We offer jaw plates made of various materials (such as high manganese steel, alloy steel, etc.) to suit different materials.

Q5: Do you provide after-sales service?

A5: Absolutely. We provide global after-sales support, including: a 12-month quality warranty, lifetime technical consultation, rapid supply of spare parts (we maintain a large inventory), and online and offline operation and maintenance training.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.