PE 250x400 Jaw Crusher With Diesel

In small to medium-sized crushing projects, operations in remote areas, or frequent relocation scenarios, the flexibility, autonomy, and reliability of equipment are far more practically significant than simply having a large production capacity.

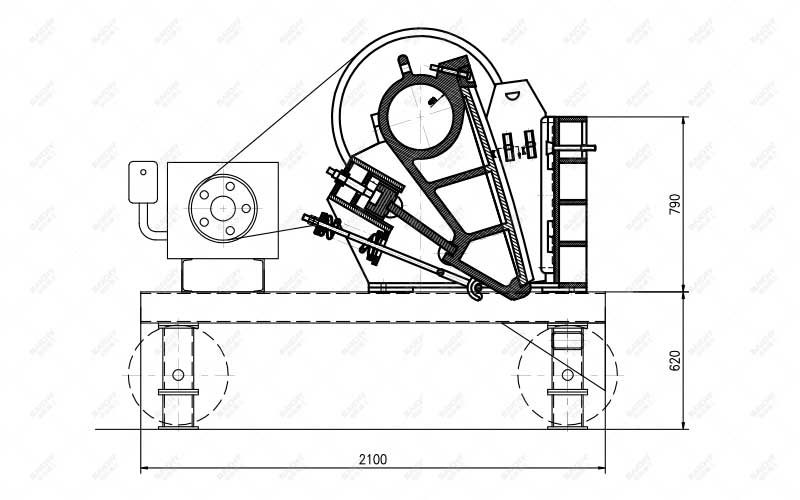

Today, we will focus on a classic model that has withstood the test of time in the market the PE250x400 mobile diesel jaw crusher and delve into why it has become a trump card for crushing basalt, bringing you a stable and efficient 20 tons/hour production capacity.

Ballast Crushing

I. Basalt Crushing: What are the Core Pain Points?

• High Hardness and High Wear: The high silica content of basalt poses a severe challenge to vulnerable parts such as jaw plates; the wear resistance of the equipment is the first hurdle.

• Numerous Site Restrictions: The approval process for building new fixed production lines is cumbersome and time-consuming. Cable laying in specific locations such as mountainous areas and riverbanks is difficult and costly.

• Investment Budget Sensitive: For small and medium-sized investors, the key to decision-making is how to achieve rapid production and quick return on investment within a limited budget.

• Flexible and Varied Demands: Short project sections and dispersed stone demand necessitate equipment capable of rapid relocation to adapt to different work surfaces.

II. Analysis of the Ace Strengths of the PE250x400 Mobile Diesel Jaw Crusher

The PE250x400 is not a new model, but its classic parameters combined with a mobile diesel engine drive precisely address the aforementioned pain points.

1. Core Power: Dual Diesel and Electric Power, Unafraid of No Power Difficulties

◦ Equipped with a mature and stable diesel engine, it delivers strong power, completely eliminating dependence on a fixed power source. Whether in remote mountainous areas or areas without power grid coverage, it starts working immediately upon ignition, greatly expanding the operating radius.

◦ Optimized fuel economy effectively controls operating costs while ensuring power, turning every drop of fuel into productivity.

2. Crushing Heart: Classic Jaw Structure, Specializing in Tough Tasks

◦ The PE series jaw crusher is a mainstay in the crushing industry, renowned for its simple structure, reliable operation, and convenient maintenance.

◦ The 250x400mm feed inlet size perfectly accommodates medium-sized basalt ore. The optimized crushing chamber design ensures strong jaw force and high crushing efficiency.

◦ High-strength manganese steel jaw plates, with optimized heat treatment processes tailored to basalt characteristics, offer wear resistance, impact resistance, and a long service life, effectively reducing the frequency and cost of replacing vulnerable parts.

3. Mobility Core: Integrated Mobile Chassis for Production Upon Deployment

◦ The PE250x400 jaw crusher, diesel engine, feeder, and conveyor are highly integrated onto a robust mobile chassis. No foundation piling is required; once the equipment arrives on site, simple site leveling is all that's needed to begin operations.

◦ During relocation, it can be moved by a tractor unit, functioning like a mobile crushing plant, perfectly adapting to the needs of multiple worksites and minimizing time costs.

4. Economic Excellence: The Golden Balance Point of 20 Tons/Hour Capacity

◦ A capacity of 20 tons/hour represents a highly cost-effective balance for small and medium-sized sand and gravel plants and engineering contracting projects. It meets the supply demands of continuous production while avoiding the investment waste and idleness caused by overly large equipment.

◦ Small investment, quick return is the core advantage of this equipment. Users can typically recover their costs in a short period and generate continuous profits, with extremely low investment risk.

III. Your Project is the Perfect Place for It

• Small and Medium-Sized Sand and Gravel Aggregate Plants: As the core coarse crushing equipment, it provides a stable source of raw materials for the sand making system.

• Urban Construction Waste Treatment: Also suitable for crushing concrete blocks, bricks, and other construction waste, achieving resource utilization.

• Highway and Railway Construction: Provides roadbed subbase materials for projects using locally sourced materials, saving significant transportation costs.

• Remote Mining: The only choice for operating without electricity; its reliability has been proven in extreme environments.

In business decisions, the wisest choice is often not the most expensive, but the most suitable. The PE250x400 mobile diesel jaw crusher, with its superior practicality, amazing flexibility, and impeccable economy, has become a magic weapon for conquering hard rocks such as basalt. It may not be a giant in terms of capacity, but it is definitely the most valiant vanguard on your profit map.

Choosing it means choosing a stable, efficient, and low-risk path to wealth. Contact us now for a customized solution to make your crushing business shine!

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.