Faced with the growing market demand for building gypsum powder and high-strength gypsum powder (α-gypsum), investing in an automated, high-output gypsum powder production line is a key focus for many entrepreneurs. This article will provide an in-depth understanding of the core processes, key equipment, and how to choose a suitable production line solution based on your specific needs.

I. Introduction to Gypsum Powder Production Lines: More Than Just Grinding

Many beginners believe that gypsum powder production is simply grinding, but this is not the case. A complete, modern gypsum powder production line is a complex system integrating crushing, grinding, calcination, modification, cooling, conveying, and packaging. Its core purpose is to process natural gypsum stone or industrial by-product gypsum (such as desulfurized gypsum and phosphogypsum) into building gypsum powder (β-gypsum) with specific setting times and strengths, or high-strength mold gypsum powder (α-gypsum).

II. Core Process Unveiled

The production process varies slightly depending on the type of gypsum powder, but the main process can be summarized as follows:

1. Raw Material Crushing and Pre-homogenization: Large pieces of gypsum stone are first coarsely crushed using a jaw crusher, then transported to a raw material silo by a bucket elevator for homogenization, ensuring stable raw material composition.

2. Raw Material Grinding: The homogenized gypsum blocks are evenly fed into a grinding mill (such as a Raymond mill or vertical mill) via an electromagnetic vibrating feeder for grinding, producing fine powder (usually 80-120 mesh) that meets calcination requirements.

3. Core Step – Calcination: This is the crucial step determining the quality of the gypsum powder. The ground raw gypsum powder is fed into calcination equipment, where some of the water of crystallization is removed at a specific temperature, transforming it into hydrated gypsum powder (hemihydrate gypsum).

Common calcination equipment includes:

◦ Fluidized bed furnace: Currently the most mainstream and efficient equipment, suitable for large-scale, continuous production, with high thermal efficiency and stable product performance.

◦ Stir-fry pan: Traditional equipment, low investment, suitable for small to medium-scale production, but relatively high energy consumption.

◦ Rotary kiln: Suitable for producing α-high-strength gypsum, using high-pressure steam in a closed environment for calcination.

4. Finished Product Cooling and Modification: The calcined gypsum powder is at a high temperature and needs to be cooled by a cooler to prevent agglomeration. Simultaneously, retarders and other additives can be added for modification according to product requirements.

5. Finished Product Storage and Packaging: The cooled and modified finished gypsum powder is conveyed to the finished product silo by a screw conveyor and finally packaged in bags or bulk using fully automatic or semi-automatic packaging machines.

III. Overview of Core Equipment in a Production Line

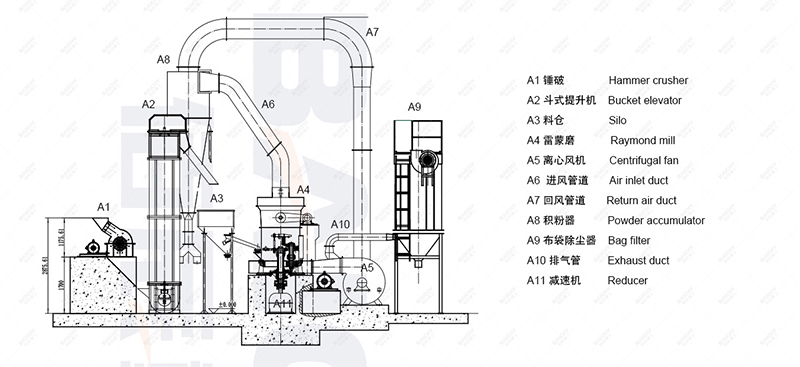

A standard production line typically includes the following equipment:

• Crushing Equipment: Jaw crusher, hammer crusher

• Grinding Equipment: Raymond mill, vertical mill, ball mill

• Calcination Equipment: Fluidized bed furnace, frying pan, rotary kiln

• Conveying and Lifting Equipment: Bucket elevator, screw conveyor, belt conveyor

• Cooling Equipment: Vibrating cooler, air-cooled system

• Dust Removal and Environmental Protection Equipment: Pulse jet bag filter, desulfurization tower

• Automation Control System: PLC control cabinet for intelligent control of the entire line

IV. How to Choose the Right Production Line Solution for You? Key Factor Analysis

When choosing a production line, you should not only focus on how much does a gypsum powder production line cost, but should consider the following comprehensively:

1. Product Positioning: Will you mainly produce building gypsum powder (β-gypsum) or high-strength gypsum powder (α-gypsum)? This directly determines the calcination process and equipment selection.

2. Raw Material Characteristics: Is natural gypsum stone used, or industrial by-product gypsum such as desulfurized gypsum or phosphogypsum? By-product gypsum usually has a high water content and requires drying treatment first.

3. Production Capacity Requirements: 10,000 tons, 50,000 tons, or over 100,000 tons per year? Production capacity determines the model and scale of equipment.

4. Investment Budget: The budget range determines the level of automation of the production line and the grade of equipment selected.

5. Site and Environmental Requirements: Plant area, height restrictions, and local environmental emission standards.

V. Regarding Investment Costs and Pricing

How much does it cost to invest in a gypsum powder production line? This is the most pressing question for customers. In reality, the price ranges from hundreds of thousands to millions of yuan because it is a highly customized system engineering project. The main factors affecting the price include:

• Automation Level: There is a huge price difference between fully automatic and semi-automatic production lines.

• Equipment Selection: Choosing between domestic first-tier brands and imported brands results in different prices.

• Production Capacity: The larger the production capacity, the larger the required equipment specifications, and the higher the total investment. • Environmental Investment: High-efficiency dust removal and desulfurization equipment is an essential cost component.

We recommend: Simply provide your specific needs (such as raw materials, target products, and budget range), and our engineers will tailor the most economical and efficient process solution for you free of charge, providing a detailed equipment quotation.

Why Choose Us?

• Professional Experience: Decades of experience in gypsum deep processing, with successful cases both domestically and internationally.

• Leading Technology: Providing advanced low-temperature calcination technology to ensure superior product performance and lower energy consumption.

• Turnkey Project Delivery: Providing one-stop turnkey project services from design, manufacturing, installation to commissioning and training.

• Lifetime Service: Providing comprehensive after-sales service and technical support to ensure long-term stable operation of the production line.

If you are planning a gypsum powder production project, please contact us immediately! Our professional engineers will provide free technical consultation and personalized production line solutions and quotations based on your needs.