In industries such as mining, building materials, and metallurgy, crushing equipment is the first hurdle in production. Jaw crushers, cone crushers, and gyratory crushers are the three mainstays of coarse and medium crushing, and their selection directly affects the efficiency and cost of the entire production line. The most frequently asked question by customers is: Which crusher offers the best price?

Gyratory Crusher PDF, Download ↓↓↓

In fact, best price cannot be determined solely by the initial purchase price; it's a complex issue that considers initial investment, operating costs, output requirements, and service life. Today, we'll conduct a thorough comparison to see which one reigns supreme in terms of cost-effectiveness.

I. Introduction to the Three Musketeers: Positioning and Characteristics

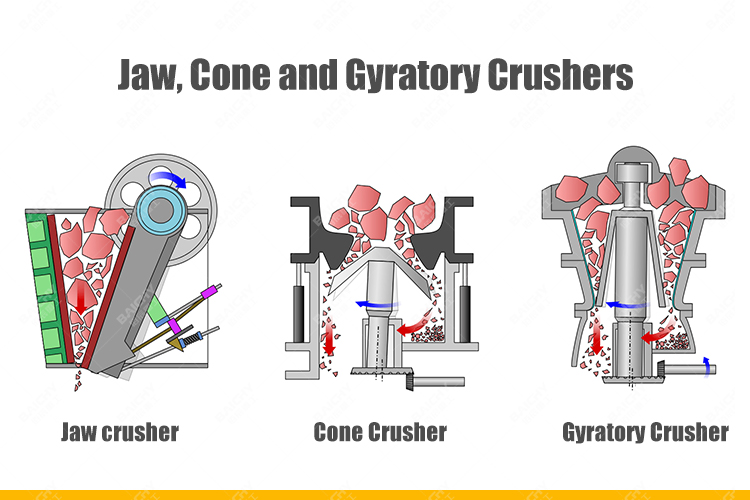

• Jaw Crusher: Coarse Crushing Pioneer. Simple structure, robust and durable, and affordable. It operates on the squeezing principle between the moving and fixed jaws, excelling at handling materials of various hardnesses, but the product particle size is relatively uneven.

• Cone Crusher: Medium Crushing Expert. Utilizes the principle of layered crushing, offering high efficiency and producing products with good particle shape and uniform particle size. • Gyratory Crusher: A more complex structure and more expensive than a jaw crusher of the same specifications, but it operates more smoothly and consumes less energy.

• Gyratory Crusher: A high-yield behemoth. Primarily used for primary crushing in large mines and quarries. It has a huge processing capacity, can continuously feed, and is extremely efficient. However, the equipment is large, the initial investment is very high, and the installation foundation requirements are stringent.

II. Optimal Price? A Multi-Dimensional Cost-Effectiveness Game

To answer which has the best price, the key lies in your return on investment calculation.

| Equipment Type | Initial Investment | Operating and Maintenance Costs | Processing Capacity | Product Particle Size | Applicable Scenarios | Core Cost-Effectiveness |

| Jaw Crusher | Lowest | Lower replacement cost for wear parts (jaw plates), but relatively high energy consumption | Medium | General, mostly needle-like and flaky particles | Small to medium-sized production lines, mobile stations, projects with limited budgets | Optimal initial investment |

| Cone Crusher | Medium | Long wear-resistant part life, high energy efficiency, but high maintenance technical requirements | High | Excellent, uniform cubic particles | Medium to large-scale production lines with high requirements for product particle shape and seeking long-term stable operation | Optimal long-term operating cost |

| Gyratory Crusher | Highest | Lowest energy consumption and cost per unit throughput, but high cost per maintenance | Very High | Good | Large and super-large mines, pursuing maximum output | Optimal unit cost under large-scale production |

Conclusion: There is no absolute optimal, only the most suitable optimal

• If your budget is limited, your output requirements are not high, and you are looking for quick production and the lowest entry cost, then a jaw crusher is your most cost-effective choice.

• If you prioritize long-term returns, have high-volume production, and strict requirements on product particle shape, and aim to reduce costs per ton, then although the initial investment is higher, the overall cost-effectiveness of a cone crusher is undoubtedly higher.

• If your project involves a giant mine processing over one million tons annually, then only a gyratory crusher can meet your capacity requirements. Its enormous processing capacity dilutes unit costs, achieving optimal pricing through economies of scale.

Selection Recommendation: When making your decision, please be sure to comprehensively consider your material characteristics, expected output, budget range, and final product quality requirements. Contact our engineers for a free selection consultation and tailor the most cost-effective crushing solution for you!