PE400×600 is a common model of jaw crusher, suitable for coarse and medium crushing operations, and is widely used in mining, building materials, highways, railways, water conservancy, and other industries.

Technical Parameters

| Model |

Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

| PE400x600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

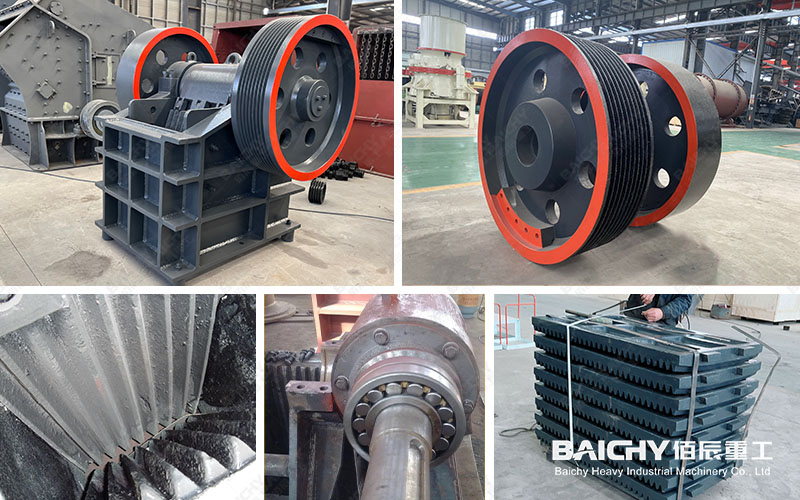

Working principle of PE400×600 jaw crusher

• Feeding: The material enters the crushing chamber from the top feed port.

• Extrusion crushing: The movable jaw plate reciprocates under the drive of the eccentric shaft, forming an extrusion effect with the fixed jaw plate to crush the material.

• Discharge: The crushed material is discharged from the bottom discharge port, and the particle size is adjusted by the discharge port.

Advantages:

• Simple structure and easy maintenance;

• Large crushing ratio (4-6), suitable for coarse crushing;

• Stable operation and strong adaptability.

Disadvantages:

• Loud noise;

• Jaw plate wears quickly (needs to be replaced regularly).

Factors affecting the price of PE400×600 jaw crusher

• Material: High manganese steel jaw plate is more expensive than ordinary materials, but has a longer life.

• Motor brand: Domestic motors (such as Nanyang motors) are cheaper, and imported motors (such as Siemens) are more expensive but stable.

• Configuration: Whether it contains belt conveyor, electric control cabinet, dust removal equipment, etc.

• Payment method: full payment vs installment (some manufacturers provide financing support).

Frequently Asked Questions (FAQ) about PE400×600 jaw crusher

Q1: Which is better, PE400×600 or PE500×750?

PE500×750 has a larger processing capacity (50-100t/h), but a higher price (120,000~200,000). If the output demand is not high, PE400×600 is more economical.

Q2: How often should the jaw plate be replaced?

Depending on the hardness of the material, generally 3-6 months (granite wears quickly, limestone wears slowly).

Q3: Can wet and sticky materials be crushed?

Yes, but it is easy to clog. It is recommended to install a vibrating feeder or adjust the discharge port.

PE400×600 jaw crusher is an ideal choice for small and medium-sized crushing production lines. It is moderately priced and has stable performance. Recommendations for purchase:

• Compare 3-5 manufacturers, and ask for trial machine videos or on-site inspections;

• Pay attention to after-sales service (warranty period, spare parts supply);

• Choose a suitable brand according to budget and production requirements.

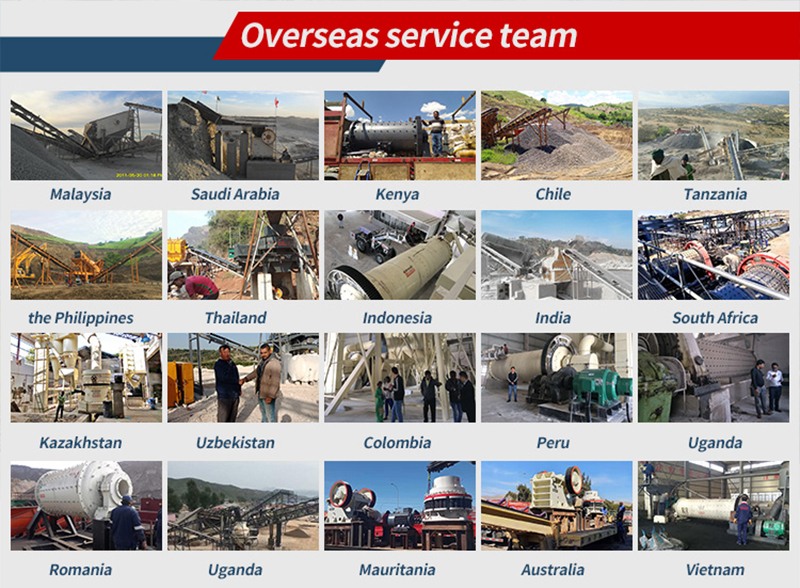

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.