What is a Gold Concentrator?

Gold Concentrator is a key equipment in the gold ore dressing process, mainly used for tailings concentration, pulp dehydration and precious metal recovery. It uses the principle of gravity sedimentation to quickly precipitate solid particles in the pulp, achieve solid-liquid separation, greatly improve the gold ore dressing efficiency, and reduce subsequent processing costs.

Core advantages:

• Efficient concentration: large processing capacity, concentration efficiency is more than 30% higher than traditional equipment.

• Energy saving and environmental protection: low energy consumption design, reduce water waste, and meet green mine standards.

• Automatic control: equipped with intelligent monitoring system, easy to operate, and reduce labor costs.

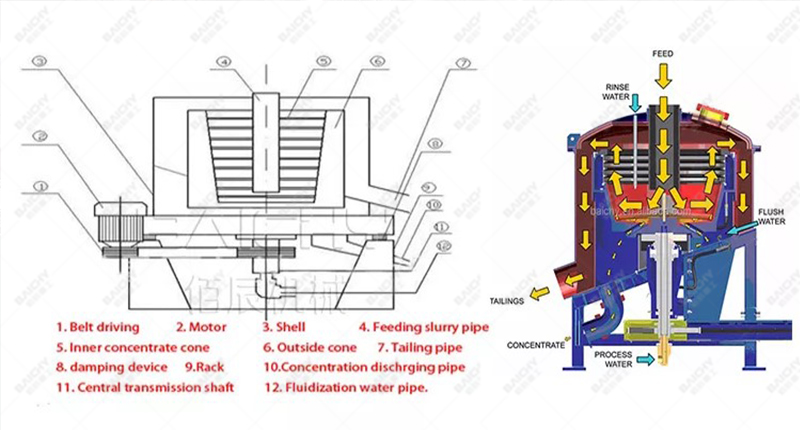

Working principle of gold concentrator

Gold concentrator is mainly based on gravity sedimentation and centrifugal force. The specific process is as follows:

• Slurry feeding: gold-containing slurry enters the center of the concentrator through the feed pipe.

• Sedimentation separation: Solid particles settle under gravity, and clean water rises to the overflow tank for discharge.

• Concentrated underflow: High-concentration slurry (underflow) is collected through the bottom discharge port to facilitate subsequent gold extraction.

• Automatic mud discharge: Some models are equipped with automatic mud scraping devices to ensure continuous and efficient operation.

Applicable scenarios:

• Tailings treatment in gold ore dressing plants

• Concentration before gold cyanide leaching

• Pre-concentration of high-grade gold ore pulp

• Gold concentrator models and selection guide

Different gold ore processing requirements correspond to different concentrator models. The following are common classifications:

| Model | Processing capacity (t/d) | Applicable slurry concentration | Features |

| BC-10 | 100-300 | 20%-40% | Applicable to small gold mines, economical and affordable |

| BC-50 | 500-1000 | 30%-50% | Mainstream model for medium-sized dressing plants |

| BC-100 | 1000-3000 | 40%-60% | Dedicated to large gold mines, high degree of automation |

Selection suggestions:

Small gold mines: BC-10 is recommended, with low investment and simple maintenance.

Medium-sized dressing plants: BC-50 is cost-effective and has stable processing capacity.

Large-scale mines: BC-100 is energy-efficient and supports intelligent control.

Maintenance and maintenance of gold concentrators

To ensure long-term and stable operation of the equipment, regular maintenance is required:

• Daily inspection: Observe the operating status of the motor and bearings to prevent overload.

• Regular cleaning: Remove sediments in the concentration tank to avoid blockage.

• Lubrication maintenance: Lubricate key parts (such as scraper tracks) regularly.

Common fault handling:

• Overflow water is turbid → Check the sedimentation rate and adjust the feed concentration.

• Underflow discharge is not smooth → Clean the discharge port or adjust the frequency of mud discharge.

Why choose a gold concentrator?

Gold concentrators are efficient equipment that improves gold recovery and reduces operating costs. They are suitable for all types of gold ore beneficiation processes. Whether it is a small mine or a large beneficiation plant, choosing the right concentrator model and matching it with the technical support of professional manufacturers can greatly improve production efficiency!

Consult Now: Get a free selection plan or quotation. Please contact Baichy Heavy Industry mining equipment experts!