In industries such as mining, building materials, and metallurgy, crushers are the core equipment for material processing. Among them, cone crushers and jaw crushers are the two most common types, but they have significant differences in structure, working principle, and applicable scenarios. This article will compare these two devices in detail to help you make the best choice based on your production needs.

Comparison of the working principles of cone crushers and jaw crushers

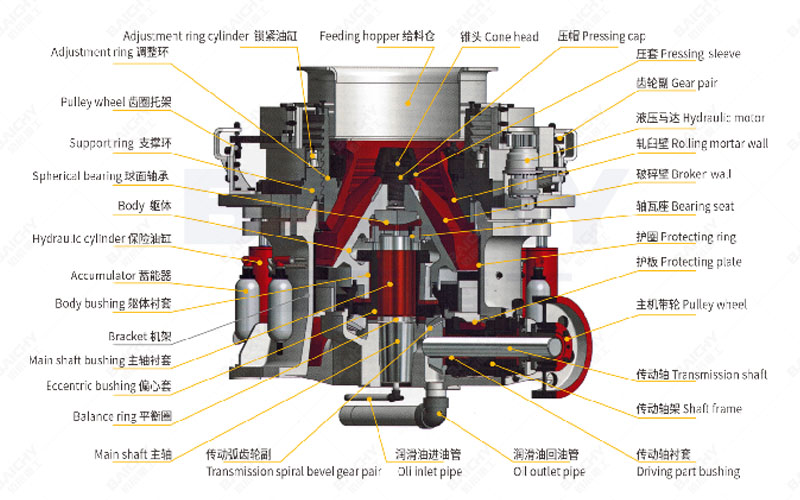

1. Cone crusher: laminated crushing, fine processing

The cone crusher adopts the principle of laminated crushing. Through the extrusion and shearing between the moving cone and the fixed cone, the material is repeatedly crushed in the crushing chamber to form uniform cubic particles.

Advantages of cone crusher:

• Large crushing ratio and uniform discharge particle size (suitable for medium and fine crushing).

• Smooth operation and low vibration, suitable for high-hardness materials (such as granite and basalt).

• High degree of automation, adjustable discharge port size.

Disadvantages of cone crusher:

• Complex structure and high maintenance cost.

• Large initial investment, suitable for large-scale production lines.

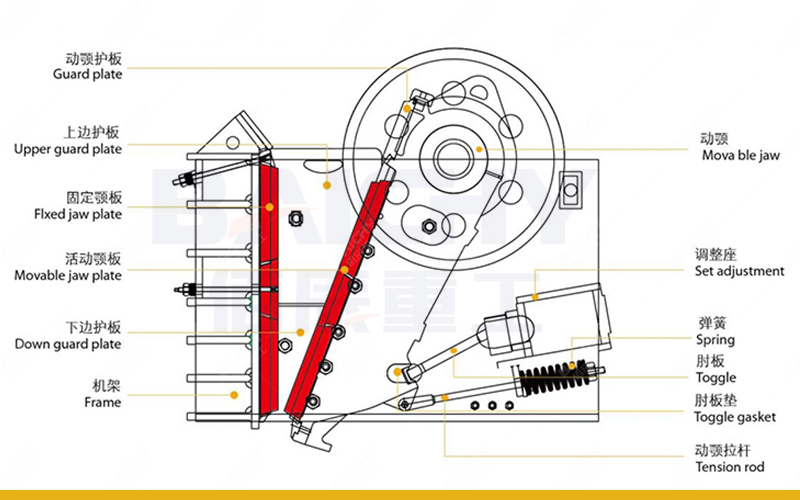

2. Jaw crusher: extrusion crushing, first choice for coarse crushing

The jaw crusher adopts the principle of extrusion crushing. Through the reciprocating motion of the movable jaw plate and the fixed jaw plate, large pieces of material are crushed into smaller particles.

Advantages of jaw crusher:

• Simple structure, easy maintenance, suitable for primary crushing (coarse crushing).

• Large processing capacity, can crush high-hardness, large pieces of material (such as iron ore, limestone).

• Low equipment price, suitable for small and medium-sized production lines.

Disadvantages of jaw crusher:

• Uneven particle size of the output material, requires screening equipment.

• Large vibration, high requirements for foundation.

The core difference between cone crusher and jaw crusher

| Comparison items | Cone crusher | Jaw crusher |

| Crushing principle | Laminated crushing (extrusion + shearing) | Extrusion crushing (moving jaw plate reciprocating motion) |

| Applicable stage | Medium and fine crushing (secondary crushing) | Coarse crushing (primary crushing) |

| Discharge particle size | Uniform, adjustable (3-60mm) | Uneven (50-300mm) |

| Applicable materials | Medium and high hardness (granite, basalt) | Various hardness (limestone, iron ore) |

| Energy consumption | Lower (low unit energy consumption) | Higher (high energy consumption for extrusion crushing) |

| Maintenance cost | Higher (complex structure) | Lower (simple structure) |

| Price | More expensive (suitable for large production lines) | Cheaper (suitable for small and medium-sized plants) |

How to choose a cone crusher or a jaw crusher?

1. Choose according to material characteristics

High hardness materials (such as granite, basalt) → Cone crusher (good wear resistance) is preferred.

Medium hardness materials (such as limestone, gypsum) → Jaw crusher (economical and efficient).

2. Choose according to production scale

Large production line (daily output of more than 1,000 tons) → Cone crusher (high efficiency, low energy consumption).

Small and medium-sized production lines → Jaw crusher (low investment, simple maintenance).

3. Choose according to discharge requirements

Need fine finished products (such as machine-made sand, gravel) → Cone crusher (uniform particle size).

Only coarse crushing is required (such as primary crushing in mines) → Jaw crusher (large processing capacity).

FAQ

Q1: Can cone crusher and jaw crusher be used together?

Yes! The "jaw crusher + cone crusher" combination is usually used:

The jaw crusher is responsible for coarse crushing, crushing large pieces of material into medium size.

The cone crusher is responsible for medium and fine crushing to ensure that the discharge meets the requirements of the finished product.

Q2: Which crusher is more power-saving?

The cone crusher has lower unit energy consumption, but the initial investment of the jaw crusher is small, and the long-term operating cost needs to be comprehensively evaluated.

Q3: Can the cone crusher replace the jaw crusher?

It cannot be completely replaced!

The cone crusher is suitable for medium and fine crushing, while the jaw crusher is more suitable for coarse crushing. The two are usually used together.

Cone crushers and jaw crushers each have their own advantages. When choosing, factors such as material characteristics, production scale, and discharge requirements need to be considered:

• Jaw crusher: The first choice for coarse crushing, economical and practical, suitable for small and medium-sized production lines.

• Cone crusher: A medium and fine crushing tool, efficient and energy-saving, suitable for large and high-hardness material processing.

If you still have questions, please leave a message and we will provide you with professional equipment selection suggestions!