Still struggling with how to choose between cone crusher and jaw crusher? This article will make an in-depth comparison from multiple dimensions such as working principle, applicable materials, production capacity, energy consumption, cost, etc., and provide the latest selection suggestions to help you make the best decision based on factors such as material hardness, production requirements, budget, etc.!

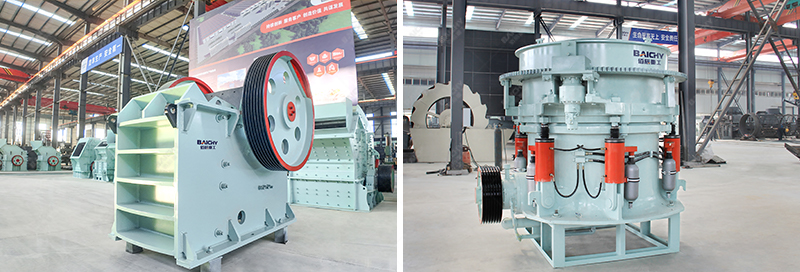

1. Cone crusher vs. jaw crusher: core differences

| Comparison items | Cone crusher | Jaw crusher |

| Working principle | Laminated crushing (extrusion + shearing) | Extrusion crushing (moving jaw reciprocating motion) |

| Applicable materials | Medium-high hardness (granite, basalt) | Medium-low hardness (limestone, shale) |

| Feed size | ≤300mm | ≤1500mm |

| Discharge size | 3-60mm (adjustable) | 10-350mm (adjustable) |

| Capacity range | 50-3000 tons/hour | 1-1000 tons/hour |

| Energy consumption | Higher (but low unit energy consumption) | Lower (but low fine crushing efficiency) |

| Maintenance cost | Higher (complex structure) | Lower (simple structure) |

| Price | More expensive (300,000-5 million) | Cheaper (50,000-1 million) |

2. How to choose? 5 key factors

2.1 Material hardness

• Cone crusher: more suitable for high-hardness rocks (such as granite and basalt), with high crushing ratio and good finished product particle shape.

• Jaw crusher: suitable for medium and low hardness materials (such as limestone and coal gangue), but wears quickly when processing hard rocks.

2.2 Production requirements

• Cone crusher: high production and high efficiency, suitable for large sand and gravel aggregate production lines (such as more than 500 tons per hour).

• Jaw crusher: flexible to adapt to small and medium production, often used for primary crushing (coarse crushing).

2.3 Discharge requirements

• Cone crusher: uniform finished product particle size, suitable for machine-made sand and high-grade aggregate production.

• Jaw crusher: wide range of discharging particle size, but high content of needle-like flakes.

2.4 Budget and Maintenance

• Cone Crusher: High initial investment, but low long-term operating cost (low unit energy consumption).

• Jaw Crusher: Affordable price, simple maintenance, suitable for projects with limited budget.

2.5 Production Line Configuration

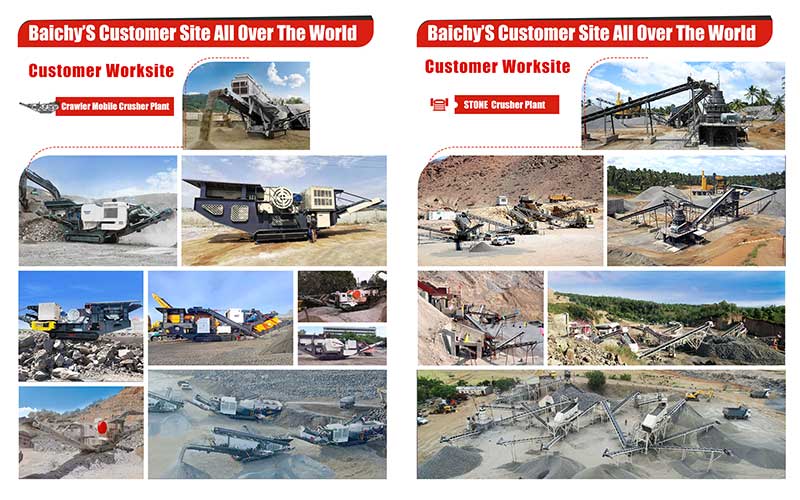

• Jaw Crusher + Cone Crusher Combination: Commonly used in large sand and gravel plants (jaw crusher for coarse crushing → cone crusher for medium and fine crushing).

• Single jaw crusher or single cone crusher: Select according to material characteristics and production capacity requirements.

3. Selection Recommendations

Choose a cone crusher if:

• Crushing high-hardness rocks (such as granite and basalt)

• High production and fine crushing are required (such as machine-made sand production)

• High requirements for finished product particle shape (such as commercial aggregate)

Choose a jaw crusher if:

• Handling medium- and low-hardness materials (such as limestone and coal gangue)

• Limited budget or simple coarse crushing is required

• Large feed particle size (such as initial crushing of raw rocks in mines)

4. Frequently Asked Questions (FAQ)

Q1: Can cone crushers and jaw crushers be used together?

Yes! Many large-scale sand and gravel production lines use a combination of "jaw crusher coarse crushing + cone crusher medium and fine crushing" to balance efficiency and cost.

Q2: How much more expensive is a cone crusher than a jaw crusher?

The price of a cone crusher is usually 2-5 times that of a jaw crusher, but it is more energy-efficient in long-term operation and suitable for high-production needs.

Q3: Which crusher is suitable for wet and sticky materials?

Jaw crusher is more suitable, cone crusher is easy to block (need to be matched with vibrating feeder).

When choosing a crusher, there is no absolute good or bad, only suitable or not. It is recommended to make a comprehensive evaluation based on material characteristics, production capacity, and budget, or consult professional equipment manufacturers to obtain customized solutions.

Need one-on-one selection guidance? Welcome to contact our technical team to provide free solution design + equipment quotation!