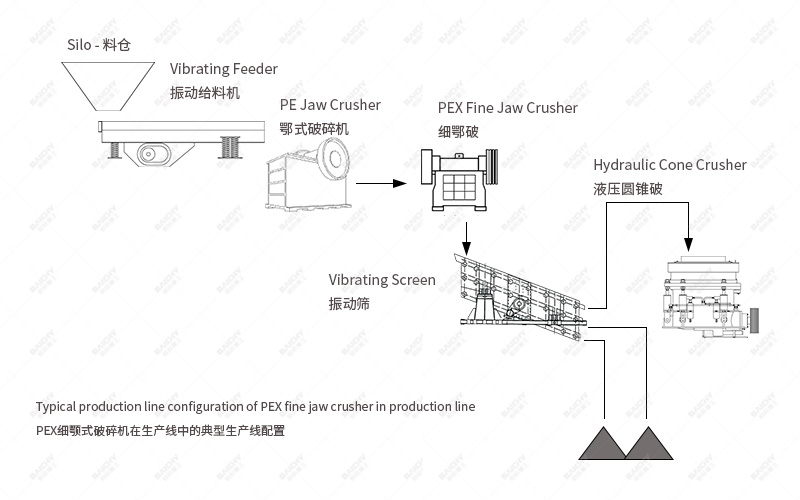

1. Typical production line configuration

PEX fine jaw crusheris usually used as secondary crushing equipment, and is used in conjunction with coarse crushing equipment (such as PE jaw crusher) and fine crushing equipment (such as cone crusher/impact crusher) in the production line. The typical configuration process is:

Raw materials → vibrating feeder → PE coarse jaw crusher (first stage coarse crushing) → PEX fine jaw crusher (second stage medium and fine crushing) → vibrating screen → cone crusher/sand making machine (final shaping) → finished product

Typical production line configuration of PEX fine jaw crusher in production line

2. Core application scenarios

• Ore crushing production line

It is used for the second-stage crushing of metal ores such as iron ore and gold ore, crushing the 100-300mm material after PE coarse crushing to 10-60mm, providing a suitable particle size for subsequent ball milling/flotation.

Advantages: lower cost than cone crusher, more resistant to the high hardness of metal ores than impact crusher.

• Building material aggregate production line

Processing hard rocks such as granite and basalt, as pre-crushing equipment before sand making, crushing the coarsely crushed materials to ≤30mm, reducing the energy consumption of the sand making machine.

Case: A granite sand making line uses "PE600×900+PEX300×1300+impact crusher", and the output is increased by 20%.

• Construction waste recycling

Medium and fine crushing of recycled materials such as concrete blocks, bricks and tiles, combined with iron removers and light material separators, to produce uniform aggregates.

Note: A dust cover needs to be installed to reduce dust pollution.

3. Key points of process adaptation

| Parameters | Requirements | Optimization suggestions |

| Feed size | ≤250mm (need to match the discharge of the front coarse crusher) | The discharge port of the front PE jaw crusher is adjusted to ≤200mm |

| Discharge requirements | 10-60mm (adjustable) | It is recommended to control ≤30mm before sand making |

| Processing capacity matching | Need to be ≥1.2 times the output of the front equipment | PEX300×1300 matches PE750×1060 for the best |

| Wet material processing | Pre-screening is required when the clay content is >5% |

4. Efficiency-enhancing configuration plan

Energy-saving plan: Add pre-screening (such as double-layer vibrating screen) after PEX fine crushing, qualified materials go directly into the finished product bin, and only oversized materials go into the subsequent sand making machine, which can reduce system energy consumption by 25%.

Automation upgrade: Install an online particle size analyzer + PLC control system to adjust the size of the discharge port in real time to ensure the stability of the discharge (±3mm error).

Wear-resistant optimization: When crushing materials with high quartz content, use a composite jaw plate (high chromium cast iron + wear-resistant alloy), which can extend the life by 2-3 times.

5. PEX fine jaw crusher maintenance guide

• Daily inspection

Lubrication system: Regularly check the lubrication of key parts such as bearings and eccentric shafts, use specified types of grease (such as lithium-based grease), and replenish it every 8 hours.

Jaw plate wear: Observe the degree of wear of the fixed jaw and the movable jaw. If there are obvious pits or cracks (wear>15%), they need to be replaced or replaced in time.

Bolt tightening: Before starting the machine, confirm that the connecting bolts of the frame, jaw plate, etc. are not loose to prevent the parts from shifting during the operation of the equipment.

• Regular maintenance

Lubrication point cleaning: Clean the oil circuit every 500 working hours and replace the lubricating oil to avoid dust blockage.

Transmission component inspection: Adjust the belt tightness to a moderate level (downward pressure range of 10-15mm), and the V-belt needs to be replaced as a whole if cracks appear.

Liner maintenance: Flip the liner over after wear (symmetrical replacement) to extend its life by 20%-30%.

• Common troubleshooting

| Fault phenomenon | Possible causes | Solutions |

| Abnormal vibration/noise | Loose bolts/jaw plate displacement | Stop the machine to tighten the bolts and reset the jaw plate |

| Discharge particle size becomes larger | Jaw plate wear/discharge port loose | Replace the jaw plate or adjust the discharge port gasket |

| Bearing overheating (>70℃) | Oil shortage or bearing damage | Replenish grease or replace bearings |

• Long-term outage maintenance

Clean the residual material in the crushing chamber to prevent rust.

Apply anti-rust oil to exposed metal parts (such as the movable jaw shaft).

Run the machine without load for 10 minutes every month to keep the transmission parts flexible.

• Safety warning

It is strictly forbidden to open the cover or reach into the chamber during operation!

Cut off the power supply and padlock during maintenance to avoid accidental start-up.

Maintenance value

Proper maintenance can extend the life of the equipment by 30%-50% and reduce energy consumption by more than 15%. It is recommended that professional technicians conduct a comprehensive inspection once a quarter.

If maintenance parameters for a specific model (such as PEX-300×1300) are required, the operating conditions can be provided for further refinement.