With the continuous development of infrastructure construction, the demand for sand and gravel aggregates remains high. A scientifically designed and efficiently operated sand and gravel production line is the key to profitability for stone quarries. A 50-ton-per-hour (50t/h) production line, with its moderate investment and high return, is an ideal choice for many small and medium-sized investors. This article will provide a comprehensive analysis of the equipment configuration, process flow, and core advantages of a 50-ton/hour sand and gravel production line.

I. Core Positioning: Why Choose a 50-ton/hour Production Capacity?

With a 50-ton/hour production capacity, based on a 10-hour working day, daily output can reach 500 tons, easily exceeding 400,000 tons annually. This production capacity scale is perfectly suited to:

• Regional sand and gravel supply: Meeting the needs of local construction, road construction, small-scale water conservancy projects, and other projects.

• Small and medium-sized investment: The initial investment is relatively manageable, the risk is low, and the payback period is short.

• Flexible production needs: Production plans can be flexibly adjusted according to market changes. II. Classic Equipment Configuration (Granite as an Example)

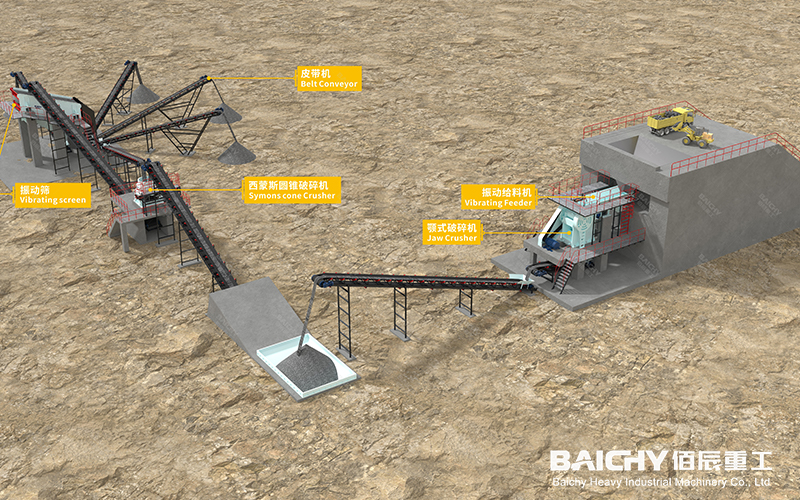

The core of an efficient sand and gravel production line lies in the perfect coordination of "crushing, screening, and conveying."

The following is a typical solution for medium-hard materials:

1. Feeding: ZSW Series Vibrating Feeder

◦ Function: Uniformly and continuously feeds raw materials from the silo to the jaw crusher, preventing blockage. It is the "throat" of the production line.

2. Primary Crushing: PE Series Deep-Cavity Jaw Crusher

◦ Function: Performs the initial crushing, reducing large lumps of raw stone to less than 250mm. Its sturdy structure and high processing capacity make it the "iron fist" of the production line.

3. Secondary Crushing: PF Series Impact Crusher or Single-Cylinder Hydraulic Cone Crusher

◦ Selection Recommendations:

▪ Impact Crusher: Produces fine-grained, cubical-shaped material, making it suitable for projects requiring high-quality stone shapes, such as high-grade highway pavement. However, it wears out relatively quickly.

▪ Cone Crusher: Highly wear-resistant, suitable for crushing hard and abrasive materials. Operating costs are low, but the finished product may contain slightly higher levels of flakes.

4. Screening: 3YK Series Circular Vibrating Screen

◦ Function: Classifies the material after secondary crushing, screening out material that meets the finished product specifications. Oversized material is returned to the secondary crusher for further crushing, forming a closed-loop system to ensure high yield and particle size.

5. Sand Making (Optional): VSI Series Vertical Shaft Impact Sand Making Machine

◦ Function: If manufactured sand is required, some of the crushed stone can be fed into the sand making machine for shaping and sand production, increasing product value.

III. Process Flow Detail

Large Stone → Vibrating Feeder → Jaw Crusher (Primary Crushing) → Impact Crusher/Cone Crusher (Secondary Crushing) → Circular Vibrating Screen (Screening) →

• Qualified Finished Product: → Belt Conveyor → Finished Product Pile

• Unqualified Large Material: → Returns to the Secondary Crusher for Further Crushing

IV. Outstanding Advantages of the Production Line

• Modular Design: The equipment features a compact layout, a small footprint, and quick installation and commissioning, enabling rapid commissioning.

• Energy-Saving and Environmentally Friendly: Multi-layer sealing and dust removal devices effectively control dust and noise, meeting environmental standards.

• High Level of Automation: A centralized electronic control system allows one person to operate the entire production line, significantly reducing labor costs.

• High Return on Investment: The equipment features long-lasting wear parts, a low failure rate, and simplified maintenance, resulting in low long-term operating costs and strong profitability.

A well-designed 50 tons/hour sand and gravel production line is more than just a production tool; it's a reliable "wealth generator." Choosing an experienced equipment supplier with professional process design, reliable equipment support, and comprehensive after-sales service is key to project success.