Vertical ultrafine grinding mill(vertical roller mill) is an efficient and energy-saving powder processing equipment, which is widely used in mining, building materials, chemical industry, metallurgy and other industries. It is suitable for ultrafine grinding of limestone, calcite, barite, slag, coal powder and other materials. The equipment adopts advanced roller grinding principle, and the fineness can reach 3000 mesh. At the same time, the energy consumption is reduced by more than 30% compared with the traditional ball mill. It is an ideal choice for modern ultrafine powder production.

Core advantages

✔ High efficiency and energy saving: optimize the grinding structure, reduce energy consumption, increase output, and achieve significant comprehensive benefits.

✔ Ultrafine grinding: The finished product fineness is 80-3000 mesh adjustable to meet the high-precision powder needs of different industries.

✔ Stable and reliable: use high-quality wear-resistant materials to extend the service life of the equipment and reduce maintenance costs.

✔ Environmental protection and low noise: fully enclosed design, dust emission meets the standard, low noise, and meets environmental protection requirements.

✔ Intelligent control: PLC automatic control system can be optionally equipped to achieve precise adjustment and improve production efficiency.

Applicable materials

Vertical ultrafine grinding mill is suitable for ultrafine processing of various non-metallic minerals and industrial solid wastes, including but not limited to:

• Non-metallic minerals: limestone, calcite, barite, talc, dolomite, bentonite, kaolin, etc.

• Industrial solid waste: slag, steel slag, water slag, fly ash, coal gangue, etc.

• Chemical raw materials: gypsum, graphite, fluorite, potassium feldspar, etc.

Technical parameters

| Model |

Grinding disc diameter (mm) |

Feed particle size (mm) |

Finished product fineness (mesh) |

Output (t/h) |

Power (kW) |

| SRM1300 |

1300 |

≤30 |

80-3000 |

5-12 |

160 |

| SRM1700 |

1700 |

≤35 |

80-3000 |

10-25 |

250 |

| SRM2200 |

2200 |

≤40 |

80-3000 |

20-50 |

450 |

Vertical roller mill vs. traditional ball mill

| Comparison item |

Vertical roller mill |

Traditional ball mill |

| Energy consumption |

Energy saving of more than 30% |

High energy consumption |

| Fineness |

Adjustable from 80 to 3000 meshes |

Generally not exceeding 800 meshes

|

| Footprint |

Compact structure, small footprint |

Large equipment, requires a large space |

| Maintenance cost |

Long life of wear-resistant parts, simple maintenance |

Fast wear of steel balls, frequent maintenance |

| Environmental protection |

Low noise, low dust |

High noise, poor dust control |

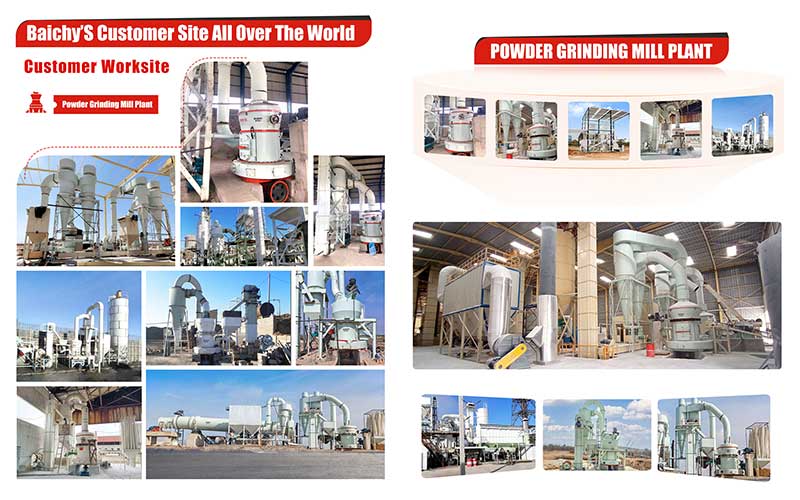

Application case

Case 1: Indonesian limestone ultrafine powder project

• Material: limestone

• Fineness requirement: D97 ≤ 10μm (about 1250 meshes)

• Equipment model: SRM1700 vertical roller mill

• Effect: Capacity 18t/h, reduced energy consumption 35%, high customer satisfaction.

Case 2: Vietnamese barite ultrafine powder processing

• Material: barite

• Fineness requirement: D90 ≤ 5μm (about 2500 mesh)

• Equipment model: SRM1300 vertical roller mill

• Effect: The fineness of the finished product is stable, and the equipment runs 5000 hours without trouble.

Frequently Asked Questions (FAQ)

Q1: What is the service life of the vertical roller mill?

A: Under normal use, the life of the core wear-resistant parts can reach 2-3 years, and the life of the whole machine 8-10 years.

Q2: How long does it take to install the equipment?

A: Standard model 7-15 days Complete installation and commissioning, and provide operation training.

Q3: Does it support non-standard customization?

A: Yes! Exclusive solutions can be customized according to material characteristics and production capacity requirements.

Vertical ultrafine grinding mill (vertical roller mill) has become the mainstream equipment in the modern powder processing industry due to its advantages of high efficiency, energy saving, ultrafine grinding, stability and reliability. If you are looking for a high-yield, low-energy, intelligent ultrafine grinding solution, please contact us for professional selection suggestions!

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.