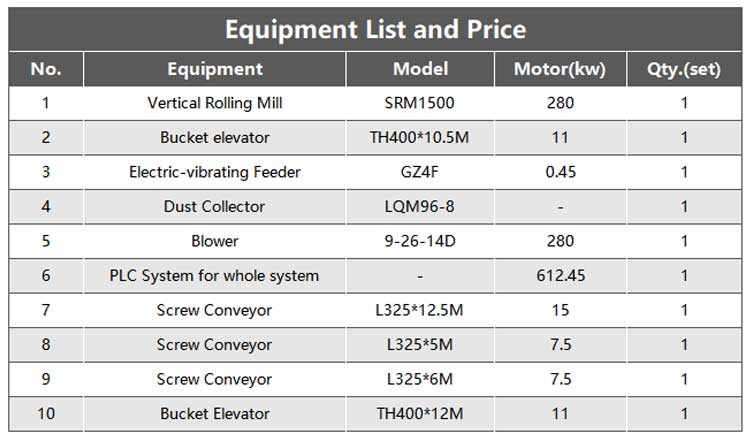

According to the customer's detailed specifications, we are pleased to offer our Vertical roller mill system SRM1500-3 for a recommendation, detailed scope below.

Vertical roller mill is an advanced grinding equipment designed and developed on the basis of extensive use of advanced technology at home and abroad, combined with years of experience in the production of vertical roller mill for various mills.

Vertical roller mill is an ideal equipment for the milling industry that integrates crushing, drying, grinding, and grading and conveying. Can be widely used in cement, electric power, metallurgy, chemical industry, non-metallic minerals and other industries. It is used to grind block, granular and powdery raw materials into the required powdery materials.

The vertical roller mill is mainly composed of powder separator, grinding roller device, grinding disc device, pressure device, reducer, motor, shell and other parts.

Separator is an efficient and energy-saving powder selection device. The grinding roller is a component used to crush and crush the material.The grinding disc is fixed on the output shaft of the reducer and is the place where the grinding rollers roll the material. The pressure device is the part that provides the grinding pressure to the grinding roller, and provides enough pressure to the grinding roller to grinding the material.

If you want to know more details, please check: DMC Pulse dust collector

Working principle of vertical roller mill

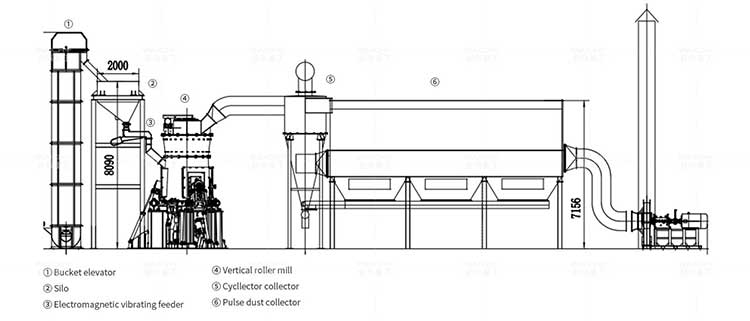

1).Feeding Parts:

The main motor drives the grinding disc to rotate through the reducer, and at the same time, the hot air enters the vertical mill from the air inlet, and the material falls into the center of the grinding disc through the feeding port.

2).Milling Parts:

When the roller table area is milled, the bulk material is directly crushed by the grinding roller, and the fine-grained material is extruded to form a material bed for inter-particle crushing. The pulverized materials continue to move to the edge of the grinding table until they are taken away by the strong airflow at the air ring. Among the materials carried by the airflow, the larger particles fall back to the grinding table under the action of their own gravity and continue to be pulverized.

3).Separating Parts:

Then it enters the high-efficiency dynamic separator with the airflow for powder classification. Under the action of the high-efficiency dynamic separator blades, the materials that do not meet the fineness requirements are returned to the grinding disc for grinding, while the materials that meet the fineness requirements pass through the pipeline with the airflow. It enters the pulse dust collector for collection, and is discharged through the discharge device as the finished powder.

4).Discharging Part:

When the hard-to-grind debris such as iron blocks mixed with the material in the main machine moves to the edge of the grinding table with the material, it cannot be blown up by the wind due to its heavy weight, and falls into the lower chamber of the grinding machine to be scraped by the scraper installed at the bottom of the grinding table to discharge the slag. After opening, discharge it to the outside of the main unit.

5).Drying Parts:

Ideally, the crushed material with a certain humidity is easier to be ground and crushed. During the operation of the main mill, the machine itself will generate an upward hot air flow. During this process, the materials with humidity below 10% are dried and achieve drying effect. Materials with substandard humidity and size fall back to the grinding table for regrinding and drying. Finally, The finished product moist is not more than 1%mass.

Related suggestion: Calcite Grinding Mill Plant / Barite Grinding Mill Plant