100 TPH Stone Crushing Production Line - The Best Choice for the Indian Market

Market Background Analysis

As a major global market for crushers, India has experienced a "golden age" of infrastructure development in recent years. By 2025, India will add 18,637 kilometers of highways, with the construction market value projected to reach US$996.19 billion, representing a CAGR of 12.6%. This massive infrastructure development directly drives a huge demand for high-quality sand and gravel aggregates, providing a vast market space for 100 TPH stone crushing production lines.

In the quarry sector, the Indian market continues to demand 20-ton excavators, while quarry owners prefer to use 250-ton and 350-ton/hour crushing equipment to process aggregates, reflecting a strong market demand for high-capacity crushing equipment. The 100 TPH stone crushing production line perfectly meets the investment needs of small and medium-sized quarries and sand and gravel producers.

Overview of a 100 TPH Stone Crushing Production Line

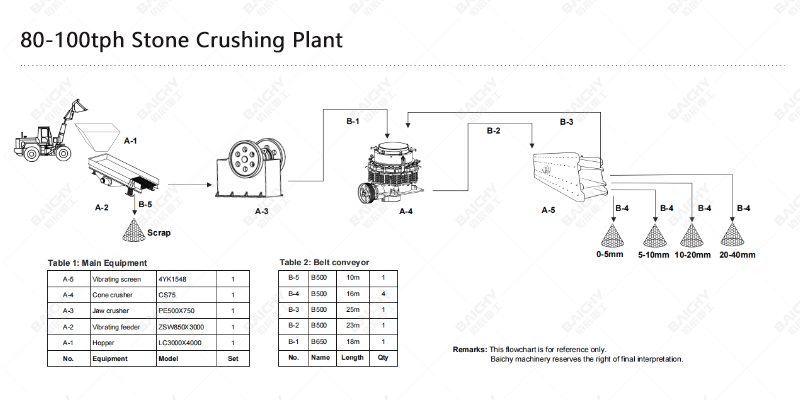

A 100 TPH (tons/hour) stone crushing production line is ideal for small to medium-sized sand and gravel processing projects. It can process various hard stones such as granite, limestone, and basalt, with a feed size up to 500mm. It can produce 3-4 different sizes of gravel, with finished product sizes ranging from 0-31.5mm. This production line offers flexible configuration and relatively low investment costs, making it suitable for small to medium-sized investors in the Indian market.

Main Configuration Options

Option 1: Jaw Crusher + Cone Crusher + Sand Making Machine Configuration

Jaw Crusher + Cone Crusher + Sand Making Machine Configuration

Core Equipment Configuration:

• Vibrating Feeder: ZSW380×95 1 unit

• Jaw Crusher: PE600×900 1 unit

• Cone Crusher: HXGYS300 1 unit

• Sand Making Machine: HX07 1 unit

• Vibrating Screen: 4YK2460 1 unit

• Conveyor: B500×15 meters (3 units)

Process Flow: Large stones are evenly fed into the jaw crusher for coarse crushing via the vibrating feeder. After crushing, the material is conveyed to the cone crusher for fine crushing, and finally fed into the sand making machine for sand making and shaping. After screening by the vibrating screen, finished aggregates of different specifications are obtained.

Option 2: Single Heavy Hammer Crusher Configuration

Core Equipment Configuration:

• Vibrating Feeder: GZD850×3000 1 unit

• Heavy Hammer Crusher: PCZ1308 1 unit

• Vibrating Screen: 2YK1854 1 unit

• Conveyor: B650×24 meters, etc.

Process Flow: This option uses a single heavy hammer crusher. The feed size can reach 1200mm, and the output size is less than 25-35mm. It achieves one-time crushing, eliminating the need for secondary crushing. The process flow is simple, and the footprint is small, making it suitable for customers with limited space.

Technical Advantages

1. High Efficiency and Energy Saving

Adopting advanced layered crushing principles and a hydraulic control system, the crushing ratio is large, production efficiency is high, and energy consumption is reduced by 15-20% compared to traditional equipment.

2. Excellent Finished Product Quality

Through multi-stage crushing and shaping processes, the finished aggregate particles are round and full, with low needle-like and flaky content, and reasonable gradation, meeting the requirements of high-standard construction aggregates.

3. Stable and Reliable Operation

Key components are made of high-strength, wear-resistant materials, resulting in a low failure rate and long service life, capable of meeting 24-hour continuous operation requirements.

4. Excellent Environmental Performance

Equipped with dust removal devices and noise reduction facilities, dust emissions and noise pollution meet environmental standards, fulfilling green production requirements.

5. High Degree of Intelligence

Utilizing a PLC automated control system, remote monitoring and fault diagnosis are achieved, making operation simple and maintenance convenient.

100 TPH Stone Crushing Production Line

Successful Cases

Case 1: Domestic 100 TPH Production Line

This customer purchased a 100 TPH stone crushing production line in 2024, employing a heavy hammer crusher configuration. Regular follow-up inspections showed stable equipment operation, a low failure rate, a high degree of automation, and the finished crushed stone particles were uniform in size and had a reasonable gradation, bringing considerable economic benefits to the customer.

Case Study 2: Baichy Heavy Industry India Project

Baichy Heavy Industry delivered 13 crushing machines to its Indian customer in a single transaction, including jaw crushers, impact crushers, sand making machines, and vibrating screens, forming a complete sand and gravel processing production line. Technical experts installed and commissioned the equipment on-site and provided technical training to local staff to ensure its proper operation.

Equipment Recommendations

1. Jaw Crusher

Recommended Models: PE600×900, PE750×1060

Features: High crushing ratio, robust structure, suitable for coarse crushing of various hard stones.

2. Cone Crusher

Recommended Models: HXGYS300, HXGYS400

Features: Employs layered crushing principle, produces good particle shape, suitable for fine crushing of medium-hard stones.

3. Sand Making Machine

Recommended Models: HX07, VSI1140

Features: Combines crushing and shaping functions, produces rounded, high-quality sand particles.

4. Vibrating Screen

Recommended Models: 4YK2460, 3YK1854

Features: High screening efficiency, capable of producing multiple specifications of finished products simultaneously.

Frequently Asked Questions (FAQ)

Q1: How much space is required for a 100 TPH stone crushing production line?

A: Depending on the configuration, the production line occupies approximately 2000-3000 square meters. If a mobile crushing station is used, the footprint can be reduced by 30-50%, and it eliminates the need for piling and is easy to relocate.

Q2: What is the replacement cycle for vulnerable parts?

A: The replacement cycle for vulnerable parts such as jaw crusher jaw plates and cone crusher liners is generally 3-6 months, depending on the material hardness and production intensity. It is recommended to maintain a stock of vulnerable parts to minimize downtime.

Q3: How long is the investment payback period for the production line?

A: Based on the price of sand and gravel in the Indian market and operating costs, the investment payback period for a 100 TPH production line is typically 12-18 months. It depends on local market conditions, raw material costs, and finished product prices.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!