| Key Words | Vertical Roller Mill Price |

|---|---|

| Product Name | Vertical Roller Mill |

| Feed Size | 0-38mm |

| Motor Power | 185-1000kw |

| Capacity | 10-120t/h |

| Core Functions | The crushing and grinding action of the rollers. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

|

Please note: The above table data is for reference only. For specific information, please contact us. |

|

1. Analysis of Vertical Roller Mill Price: What Determines the Cost?

Vertical roller mill prices are not fixed, but affected by multiple core factors. As a professional manufacturer, we analyze these key elements in detail to help you avoid blind purchases and choose products matching your budget and needs.

1.1 Equipment Specifications & Production Capacity

This is the most direct factor affecting price. Our vertical roller mills have hourly output of 10t/h-120t/h, installed power of 185KW-1000KW, feed particle size ≤50mm and discharge fineness 80-3000 mesh. Small models (10-30t/h) cost $3,000-$50,000 (for small plants/laboratories); medium models (30-60t/h) $50,000-$150,000 (widely used in mining/building materials); large models (above 60t/h) $150,000-$800,000+ (for large production lines like cement plants).

1.2 Core Components Quality

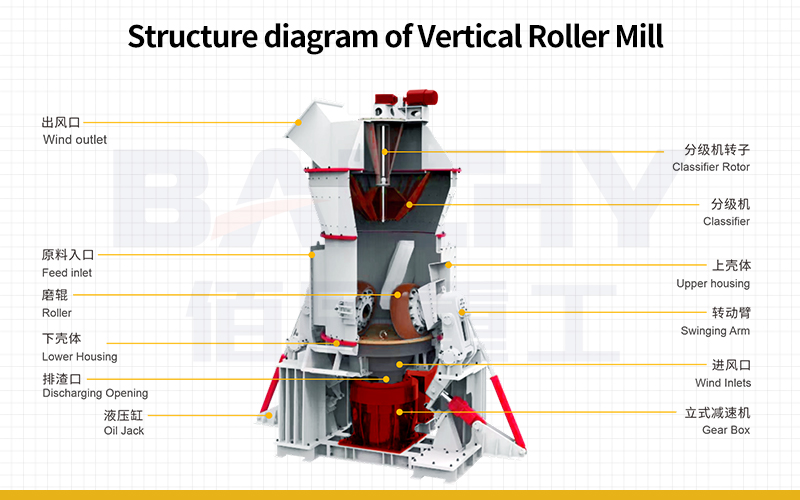

Core components (grinding rollers, discs, hydraulic systems, classifiers) directly determine service life, stability and price. We use high-wear-resistant alloy for grinding parts (extending service life by 2-3 times) and well-known brand hydraulic/control components to reduce failure rates. Though high-quality components increase initial cost, they save long-term maintenance expenses.

1.3 Customization Requirements

Customizations (e.g., drying systems for high-moisture materials ≤15%, ultra-fine fineness 3000 mesh, corrosion-resistant materials) will increase prices. We provide personalized solutions with reasonable quotes based on your specific needs.

2. Overview of Vertical Roller Mill: What Is It & Where Is It Used?

Vertical roller mills integrate crushing, grinding, drying, grading and conveying, gradually replacing traditional ball mills as the preferred grinding equipment in many industries.

2.1 Working Principle

Adopting "material-bed grinding", the motor drives the grinding disc via reducer. Materials spread to the disc edge by centrifugal force, are ground by hydraulic-pressed rollers, and carried by hot air to the classifier. Qualified fine powder is collected as finished products; coarse powder is re-ground. The whole process is fully automated.

2.2 Application Scope

Widely used in mining, building materials, chemical, metallurgy and power industries, it grinds non-flammable/non-explosive materials (Mohs hardness ≤7) such as limestone, slag, coal and quartz. Its application scope and market demand are constantly expanding.

3. Advantages of Our Vertical Roller Mill: Why Choose Us?

Our vertical roller mills have obvious advantages in quality, efficiency, cost and after-sales, with more competitive prices. Core advantages are as follows:

3.1 High Efficiency & Energy Saving

Saves 20%-50% energy vs. ball mills. Its strong drying capacity (handles materials ≤15% moisture) eliminates the need for additional drying equipment, improving efficiency and reducing costs.

3.2 Stable Quality & Long Service Life

Strict quality control ensures core components (wear-resistant alloy) have a 5-8-year service life (2-3 times longer than ordinary models). The advanced automatic control system keeps failure rate below 3%, enhancing production efficiency.

3.3 Reasonable Price & Transparent Pricing

As a direct manufacturer, we avoid intermediate markups, offering prices 10%-20% lower than trade companies. Transparent pricing (no hidden costs) and tailored recommendations help you choose cost-effective products.

4. Real Case: Our Vertical Roller Mill Cooperation & Price Reference

Below are two real cases (prices for reference only; specific prices adjust with market, specifications and customization).

4.1 Case 1: Indonesian Medium-Sized Limestone Processing Plant

Demand: 30t/h limestone, 200 mesh, drying system (12% moisture), energy-saving and stable.

Solution: VR-30 medium vertical roller mill with drying system and automatic control.

Price: $95,000 (including installation/commissioning/training; excluding transportation/customs).

Feedback: Stable operation for 2 years, low energy consumption, qualified products, timely after-sales, 1.5-year expected cost recovery.

4.2 Case 2: Turkish Large-Scale Slag Processing Plant

Demand: 80t/h blast furnace slag, 325 mesh, high stability/efficiency, customized classifier.

Solution: VR-80 large vertical roller mill with optimized classifier, imported hydraulic components and dust removal system.

Price: $320,000 (including customization/installation/commissioning/training; excluding transportation/customs).

Feedback: 85t/h output (exceeding expectation), 30% energy saving vs. ball mill, uniform particle size, satisfactory customization and professionalism.

5. Related Equipment Recommendation: Support Your Production Line

We provide full-set supporting equipment at reasonable prices to improve efficiency and reduce procurement costs. Key recommendations:

5.1 Jaw Crusher

Primary crushing of raw materials (≤1000mm to ≤50mm), simple structure, high efficiency, price $15,000-$80,000 (by model/capacity).

5.2 Belt Conveyor

Conveys materials between equipment, stable and adjustable, price $5,000-$30,000 (by length/capacity).

5.3 Dust Removal Equipment

Collects dust (efficiency ≥99%), meets environmental standards, price $8,000-$50,000 (by treatment capacity).

5.4 Control System

Automatic centralized control of production line, reduces manual operation, price $10,000-$40,000 (by complexity).

6. FAQ About Vertical Roller Mill Price: Answers to Your Most Concerned Questions

We answer 3 common questions to solve your doubts about vertical roller mill prices:

Q1: Do customization services affect the vertical roller mill price? What customizations are available?

A1: Yes, customization services will increase the price appropriately, and the specific increase depends on the customization requirements. Common available customizations include adding drying systems for materials with moisture ≤15%, optimizing discharge fineness to 3000 mesh, using corrosion-resistant materials for special working environments, and upgrading the control system to full intelligent operation.

Q2: Why is there a price difference between your vertical roller mill and small manufacturers?

A2: The core reason lies in the quality of components and after-sales service. Small manufacturers use ordinary materials for core parts (such as grinding rollers and discs) to reduce costs, resulting in short service life and high failure rate. We adopt high-wear-resistant alloy components and well-known brand accessories, and provide professional after-sales service (warranty, on-site maintenance, etc.), so the price is slightly higher but more cost-effective in the long run.

Q3: What is the average price of a vertical roller mill? Is there a minimum order quantity?

A3: Prices vary by model: small (10-30t/h) $3,000-$50,000; medium (30-60t/h) $50,000-$150,000; large (above 60t/h) $150,000-$800,000+. No minimum order quantity; bulk orders get preferential policies.

Get Quotes

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet perse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!