| Product Name | Vertical Roller Mill |

|---|---|

| Key Words | High-Efficiency Vertical Roller Cement Mill |

| Feed Size | 0-38mm |

| Motor Power | 185-1000kw |

| Capacity | 10-120t/h |

| Core Functions | The crushing and grinding action of the rollers. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

1. Analysis of High-Efficiency Cement Mill: Core Value & Market Demand

The high-efficiency cement mill is an upgraded version of the traditional cement mill, which solves the pain points of low grinding efficiency, high energy consumption and unstable product quality of traditional equipment. With the continuous development of the cement industry and the increasing requirements for energy conservation and environmental protection, the market demand for high-efficiency cement mill is growing rapidly, and its core value is mainly reflected in two aspects: improving production efficiency and reducing comprehensive costs.

1.1 Key Factors Determining the Efficiency of High-Efficiency Cement Mill

The "high efficiency" of thehigh-efficiency cement mill is not accidental, but is determined by multiple core factors. First, the optimized structural design, such as the reasonable matching of grinding rollers and grinding discs, reduces the energy loss during the grinding process. Second, the advanced grinding principle adopts the material bed grinding technology, which makes the materials grind more fully and improves the grinding efficiency by 30%-50% compared with the traditional ball mill. Third, the intelligent control system realizes the automatic adjustment of the grinding process, avoids manual operation errors, and ensures the stable operation of the equipment. In addition, the quality of core components (such as wear-resistant grinding rollers and hydraulic systems) also directly affects the efficiency and service life of the high-efficiency cement mill.

1.2 Market Demand Trend of High-Efficiency Cement Mill

With the global emphasis on energy conservation and environmental protection, more and more cement plants are upgrading their production lines and replacing traditional cement mills with high-efficiency cement mill. Especially in developing countries and regions, the demand for infrastructure construction is large, and the demand for cement is increasing, which further drives the market demand for high-efficiency cement mill. At the same time, the market has higher and higher requirements for the performance of high-efficiency cement mill, such as higher output, lower energy consumption, better environmental protection and more intelligent operation, which also promotes the continuous upgrading and improvement of the equipment.

2. Overview of High-Efficiency Cement Mill: Working Principle & Application

To better understand the high-efficiency cement mill, we will elaborate on its working principle, structural characteristics and application scope, helping you have a comprehensive understanding of this equipment.

2.1 Working Principle of High-Efficiency Cement Mill

The high-efficiency cement mill adopts the advanced material bed grinding principle. The motor drives the grinding disc to rotate through the reducer. The raw materials (such as clinker, gypsum, etc.) enter the grinding chamber through the feeding device and spread evenly on the grinding disc under the action of centrifugal force. The grinding roller presses the materials tightly under the action of hydraulic pressure, and grinds the materials into fine powder during the rotation of the grinding disc. At the same time, the hot air enters the grinding chamber from the bottom of the equipment, carries the fine powder to the classifier for sorting. The qualified fine powder (meeting the fineness requirement of cement) is collected as the finished product, and the unqualified coarse powder falls back to the grinding disc for re-grinding. The whole process is fully automated, which not only improves the production efficiency, but also ensures the stability of the product quality.

2.2 Structural Characteristics

The high-efficiency cement mill has a compact structure, integrating grinding, drying, grading and conveying functions, which saves the floor space of the equipment and reduces the investment cost of the production line. Its core components include grinding disc, grinding roller, hydraulic system, classifier and intelligent control system. The grinding roller and grinding disc are made of high-wear-resistant alloy materials, which have strong wear resistance and long service life. The hydraulic system adopts well-known brand components, which has stable performance and convenient maintenance. The intelligent control system can realize real-time monitoring and automatic adjustment of the equipment operation parameters, reducing the labor intensity of operators.

3. Advantages of Baichy High-Efficiency Cement Mill: Why Choose Us?

As a professional mining crushing and grinding equipment manufacturer, Baichy has rich experience in the R&D and production of high-efficiency cement mill. Our equipment has obvious advantages in quality, efficiency, energy conservation and after-sales service, which is favored by global customers.

3.1 High Efficiency & Energy Saving

Baichy high-efficiency cement mill adopts optimized structural design and advanced material bed grinding technology, which can save 20%-40% of energy compared with traditional ball mills. At the same time, the grinding efficiency is significantly improved, and the hourly output can reach 10-150t/h, which can meet the production needs of different scales of cement plants. The strong drying capacity can handle materials with moisture content up to 12%, avoiding the need for additional drying equipment and reducing the production cost.

3.2 Stable Quality & Long Service Life

Baichy adheres to the principle of "quality first", and all high-efficiency cement mill products have passed strict quality inspection before leaving the factory. The core components (grinding roller, grinding disc, hydraulic system, etc.) are made of high-quality materials and well-known brand accessories, which ensures the stable operation of the equipment and reduces the failure rate. The service life of the grinding roller and grinding disc can reach 5-8 years, which is 2-3 times that of ordinary cement mills, greatly reducing the later maintenance cost.

4. Real Application Case of Baichy High-Efficiency Cement Mill

Below is a real application case of Baichy high-efficiency cement mill, which shows the actual use effect of the equipment, for your reference (the specific price and configuration can be adjusted according to the customer's needs).

4.1 Case: Indian Medium-Sized Cement Plant

Demand: The customer is a medium-sized cement plant in India, mainly producing ordinary Portland cement. The original equipment is a traditional ball mill, which has the problems of low output, high energy consumption and unstable product quality. It is hoped to replace it with a high-efficiency cement mill to improve production efficiency, reduce energy consumption and ensure the fineness of cement (325 mesh).

Solution: According to the customer's demand, Baichy recommended the HC-60 high-efficiency cement mill, equipped with an intelligent control system and a drying device (to handle the moisture content of raw materials up to 10%). The equipment has an hourly output of 60t/h, an installed power of 315KW, and can stably produce cement with 325 mesh fineness.

Price: $180,000 (including equipment, installation, commissioning and training, excluding transportation and customs fees).

Customer Feedback: The Baichy high-efficiency cement mill has been in stable operation for 18 months. Compared with the original ball mill, the energy consumption is reduced by 35%, the output is increased by 40%, and the cement fineness is uniform and stable, which meets the national standard. The intelligent operation is convenient, and the number of operators is reduced by half. The after-sales service of Baichy is also very professional, and the maintenance personnel can arrive at the site in time when there is a problem, which solves our worries.

5. Related Supporting Equipment Recommendation

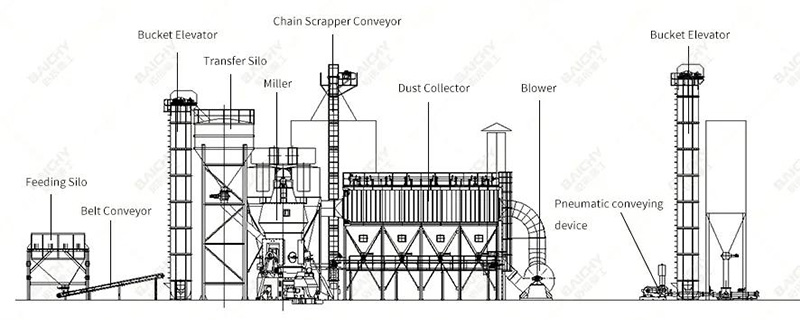

To help customers build a complete cement production line, Baichy provides a full set of supporting equipment for the high-efficiency cement mill, with reasonable prices and reliable quality, which can improve the overall efficiency of the production line and reduce procurement costs.

5.1 Jaw Crusher

Used for primary crushing of cement raw materials (such as clinker, limestone), crushing large-size raw materials into small particles (≤50mm) that meet the feeding requirements of the high-efficiency cement mill. The price ranges from $18,000 to $85,000, with simple structure, high crushing efficiency and easy maintenance.

5.2 Belt Conveyor

Used for conveying materials between equipment (such as from jaw crusher tohigh-efficiency cement mill, from cement mill to finished product warehouse), with stable conveying, adjustable speed and large conveying capacity. The price ranges from $6,000 to $35,000, depending on the length and conveying capacity.

5.3 Dust Removal Equipment

Used for collecting dust generated during the operation of the high-efficiency cement mill and other equipment, meeting environmental protection standards, protecting the environment and the health of operators. The price ranges from $9,000 to $55,000, with high dust removal efficiency (≥99.5%) and low energy consumption.

6. FAQ About High-Efficiency Cement Mill: Answers to Your Concerns

We have sorted out 3 common questions abouthigh-efficiency cement mill, and given detailed answers to help you solve your doubts and make better purchasing decisions.

Q1: What is the average price of Baichy high-efficiency cement mill? Is there a minimum order quantity?

A1: The price of Baichy high-efficiency cement mill varies according to the model and configuration. The small model (10-30t/h) is about $40,000-$120,000, the medium model (30-80t/h) is about $120,000-$250,000, and the large model (above 80t/h) is about $250,000-$900,000 or higher. There is no minimum order quantity. Whether you need 1 set or multiple sets, we can provide you with reasonable quotes and professional services. For bulk orders, we will give preferential policies to further reduce your procurement costs.

Q2: How long is the warranty period of Baichy high-efficiency cement mill? What after-sales services are provided?

A2: Baichy provides a 1-2 year warranty period for the high-efficiency cement mill (the warranty period of core components is extended appropriately). During the warranty period, if the equipment fails due to quality problems, we will provide free maintenance and replacement of damaged components. In addition, we also provide free on-site installation, commissioning and operator training; 48-hour on-site maintenance service (adjusted according to the overseas region); and lifelong maintenance support, providing technical guidance and component replacement services for the equipment during the entire service life.

Q3: Can Baichy high-efficiency cement mill be customized according to my specific needs? What customization services are available?

A3: Yes, Baichy can provide personalized customization services for the high-efficiency cement mill according to your specific needs. Common customization services include: optimizing the output and fineness of the equipment (such as adjusting the hourly output to 50t/h, the fineness to 400 mesh), adding a drying system for high-moisture materials, using corrosion-resistant materials for special working environments, and upgrading the control system to full intelligent operation. The specific customization content and price can be negotiated according to your needs.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!