In the fields of mining, aggregate production, and large-scale infrastructure construction, stationary crushing plants have always been a cornerstone. When you seek a stable, high-yield, and long-term crushing solution, a stationary crushing plant with a capacity of 30 tons per hour (30 TPH) is often an ideal choice for entry-level or small-to-medium-sized production lines. This article will delve into the value of a 30 TPH stationary crushing plant and explore whether it remains the wisest investment decision today.

I. Overview of the 30 TPH Stationary Crushing Plant

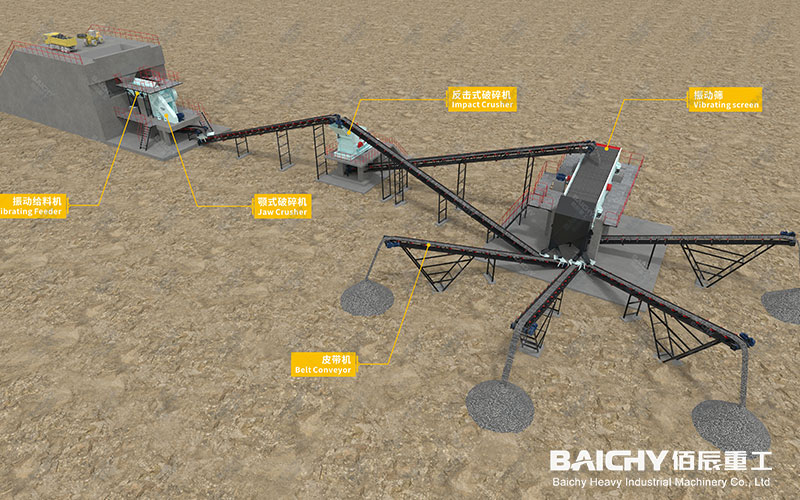

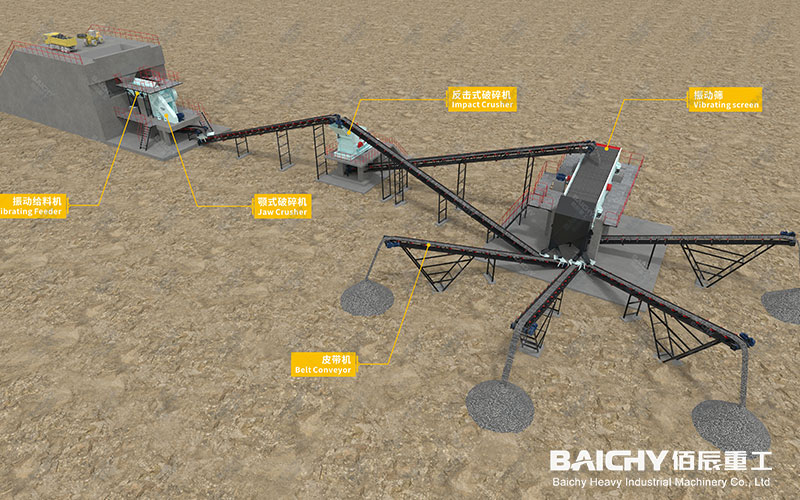

A 30 TPH stationary crushing plant, as the name suggests, is a non-mobile integrated processing system designed for a theoretical output of 30 tons of stone per hour. It typically consists of feeding, crushing, screening, and conveying equipment modules installed and connected in a fixed location, forming a continuous assembly line. This production line is suitable for processing various materials such as limestone, granite, pebbles, and construction waste, producing finished aggregates of different specifications, and is widely used in commercial concrete plants, road construction, railway ballast, and other fields.

| Key Words |

30 TPH Stationary Stone Crusher Plant |

| Product Model |

Stone Crushing Plant |

| Capacity |

0-2000t/h |

| Core Advantages |

Multi-stage fragmentation and reshaping |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

II. Analysis of the Traditional Advantages of Stationary Crushing Plants

The reason why stationary crushing solutions have maintained a significant market share for many years is due to their significant inherent advantages:

1. High Stability and Continuous Operation Capability

Stationary production lines have a solid foundation, and each link is tightly connected, allowing for uninterrupted operation 24/7, which is particularly suitable for medium-to-large-sized quarries or fixed material yards with stable production demands.

2. Lower Operating Costs and Convenient Maintenance

Because the equipment is fixedly installed, its power system, lubrication system, etc., can be centrally arranged, optimizing energy consumption. At the same time, the fixed platform provides ample space and convenient conditions for daily maintenance, upkeep, and major repairs, reducing long-term operation and maintenance costs in terms of manpower and time.

3. Strong Customization and Expansion Potential

In the initial project planning, stationary production lines can be highly customized according to raw material characteristics and finished product requirements (such as choosing different combinations of jaw crushers + cone crushers, or impact crushers + sand making machines). If capacity expansion is needed in the future, it is easy to add equipment and extend the process based on the original production line.

III. A Classic Case Study: Transformation of a Medium-Sized Quarry

A medium-sized limestone quarry in East China originally used decentralized, old-fashioned single-machine operations, resulting in low efficiency, high dust levels, and a finished product qualification rate of less than 80%. In 2019, the quarry invested in and built a fixed crushing and screening production line with a capacity of 30 tons per hour, configured with a classic closed-circuit process of "vibrating feeder + jaw crusher (coarse crushing) + cone crusher (medium and fine crushing) + circular vibrating screen".

Results: After the production line was put into operation, it achieved fully automated control, with a stable output of 32-35 TPH. The finished aggregate had excellent particle shape and a qualification rate of over 95%. Although the initial civil engineering and equipment installation investment was high, the costs were recovered within three years through stable capacity and high-quality products, becoming a benchmark production line in the region.

IV. From the Perspective of a Mobile Crushing Equipment Manufacturer: Relevant Recommendations and Considerations

Although the 30 TPH fixed production line has obvious advantages, as a leading manufacturer of mobile crushing equipment for mining, we must point out that in today's market environment, customers have more flexible and cost-effective options—mobile crushing plants.

For the following scenarios, we strongly recommend considering our mobile crushing solutions:

Short project cycle (1-3 years) or dispersed work sites: Mobile plants are easy to relocate and do not require large-scale civil engineering.

Limited site space or complex terrain: Mobile plants are highly integrated and can reach the work face directly.

Limited initial investment budget: Mobile plants can operate as single units, allowing for phased investment as needed, lowering the entry barrier.

Extremely high environmental protection requirements: Modern mobile plants are equipped with comprehensive dust removal and noise reduction systems and can be quickly moved away from sensitive areas.

A set of 30 TPH wheeled mobile jaw crusher or impact crusher combinations offers flexibility that fixed lines cannot match. We recommend that investors comprehensively compare the total life cycle costs (including infrastructure, installation, operation, relocation, etc.) of fixed and mobile solutions before making a decision on a 30 TPH crushing solution.

Mobile Jaw Crusher

Mobile Impact Crusher

V. Frequently Asked Questions (FAQ)

Q1: What is the approximate total budget for a 30 TPH fixed crushing production line?

A1: The price range is quite wide, mainly depending on the equipment brand, configuration complexity (number of crushing stages, number of screening layers), and degree of automation. A basic configuration of a domestically produced production line may cost between 300,000 and 800,000 RMB. However, additional costs for civil engineering foundations, power facilities, installation, and commissioning must be included, which may account for 20%-50% of the equipment cost.

Q2: How long does it take from installation to commissioning for a fixed production line?

A2: This depends on the scale of the production line and site conditions. For a standard 30 TPH line, it usually takes 1-2 months from equipment arrival to complete foundation construction, equipment installation, and system debugging. Initial site planning and power application may take longer.

Q3: As an equipment manufacturer, do you offer fixed production lines? How do they compare to mobile crushing plants?

A3: As a professional manufacturer, we provide both fixed core single machines (such as jaw crushers and cone crushers) and complete mobile crushing and screening plants. The key to choosing depends on your specific project requirements. If the raw material source is single, the production cycle is longer than 5 years, and you require ultimate stability and low cost, a fixed line is the preferred option. If you prioritize flexibility, rapid commissioning, and adaptability to multiple locations, then our mobile crushing plant will be a more efficient and economical solution. We can provide you with free solution design and comparison services.

Investing in a 30 TPH fixed aggregate production line is an important long-term decision. It represents a classic model of stability, reliability, and continuous returns. However, in the face of a rapidly changing market and increasingly diverse project needs, mobile crushing solutions are becoming the new favorite of more and more savvy investors due to their unparalleled flexibility and ever-improving efficiency.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!