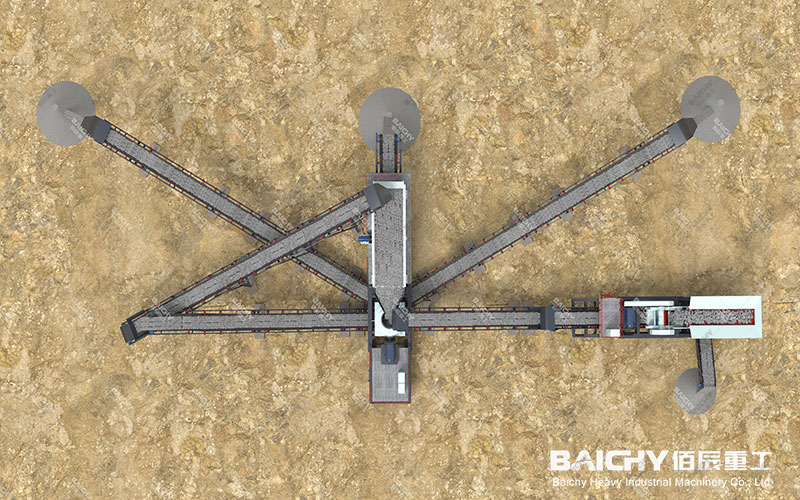

The mobile crushing line configuration (mobile jaw crusher + mobile cone crushing and screening station) is a classic and highly efficient combination, especially for processing hard rock ores.

Below, I will answer your two questions in detail.

1. Typical Application Scenarios of This Line

This mobile crusher combination of "jaw crusher + cone crusher + screening" is primarily used in the following scenarios due to its high efficiency, stability, and high-quality finished product:

1. Large-scale mining: particularly metal ores (such as iron and copper) and limestone mines for large cement plants. These applications require large, hard raw materials with high throughput, perfectly leveraging the advantages of the jaw crusher's powerful coarse crushing and the cone crusher's efficient medium and fine crushing.

2. Large-scale construction aggregate production: Specialized in providing high-quality concrete aggregate and foundation stone for large infrastructure projects such as highways, railways, dams, and airports. The cone crusher's "laminated crushing" principle produces cubic particles with excellent particle shape and low flake content, meeting the material standards for high-end construction.

3. Hard Rock Crushing: Specifically designed for crushing medium-to-high-hardness and highly abrasive rocks such as granite, basalt, quartz, and diabase. This is the core application area for cone crushers, whose wear resistance and stability far exceed those of impact crushers and other equipment.

4. Projects requiring continuous operation and limited space: Mobile crushers with built-in axles and tires enable combined operation, reducing truck transportation costs for intermediate material transfers. They are suitable for flexible movement within a mining area or quarry as the work surface advances.

Core Features Summary: This configuration is a "heavy-duty weapon" for handling high-hardness, large-block, and high-volume materials, aiming to produce high-quality, controllable-size, small- to medium-sized finished aggregates.

II. How is it used for crushing granite?

It is very suitable, even one of the top configurations for crushing granite.

Granite is a typical hard and highly abrasive rock, requiring equipment with high crushing force, high stability, and high wear resistance. Your production line meets all of these requirements:

1. Jaw Crusher (Primary Crushing):

• Advantages: Its powerful crushing force and large feed opening make it ideal for handling the large granite lumps produced by blasting. Its sturdy structure can stably withstand the high impact and compression of granite.

• Note: The jaw plates should be made of high-manganese steel or a more wear-resistant composite alloy to cope with the highly abrasive nature of granite.

2. Mobile Cone Crusher and Screening Station (Secondary & Screening):

• Core Advantage: This is the best choice for crushing granite. Cone crushers utilize the principle of laminated crushing, achieving crushing through compression and grinding between rocks rather than simple impact.

• High Efficiency and High Yield: Laminated crushing is extremely efficient, ensuring stable high output.

• Excellent Particle Shape: The finished product is mostly cubic with low flake content, making it an ideal shape for high-quality concrete aggregate.

• Wear-resistant and durable: Both the moving and fixed cones are inlaid with high-strength wear-resistant liners for a long service life, making them ideal for crushing highly abrasive materials like granite.

• Screening equipment: Built-in or tightly coupled screening equipment can promptly screen out materials of acceptable particle sizes, returning unqualified coarse material to the cone crusher for further crushing (closed-circuit circulation), ensuring uniform finished material specifications and efficient production.

Granite crushing workflow:

Raw ore (large granite lumps) → Mobile jaw crusher station (coarse crushing to less than 250mm) → Conveyor belt → Mobile cone crusher and screening station (secondary and fine crushing and screening) → Output of finished aggregates in a variety of sizes (e.g., 0-5mm, 5-10mm, 10-20mm, 20-31.5mm, etc.).

The mobile jaw crusher + mobile cone crusher and screening station configuration you described is an ideal solution for granite crushing. It not only performs crushing tasks efficiently and stably, but also produces high-quality aggregate with a well-shaped and high-grade particle size, thereby achieving higher market prices and economic benefits.

Final Tip:

When selecting a specific model, be sure to consider the maximum particle size of your granite raw material, your desired output (tons/hour), and the desired final product specifications to ensure optimal production line configuration.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)