Jaw Crusher Stone Rock Concrete Crushing Equipment

In the fields of mining, aggregate production, and construction waste recycling, the jaw crusher is an indispensable core equipment for the primary crushing stage. With its robust structure, efficient crushing capabilities, and wide applicability, it has become the preferred solution for processing various hard materials (such as granite, basalt, quartz, concrete, etc.).

As a mining crushing equipment manufacturer with 20 years of R&D and manufacturing experience, we deeply understand the technical essence and market application needs of jaw crushers.

| Key Words | Rock Concrete Crushing Equipment |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | 100-1200mm |

| Motor Power | 30-280kw |

| Capacity | 0-1200 t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Equipment Overview and Working Principle

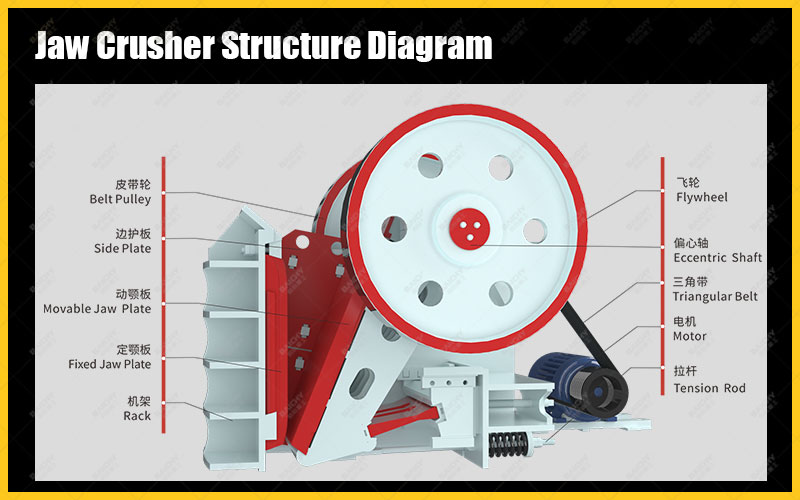

The jaw crusher, or jaw breaker, is inspired by the biting action of animal jaws. The core structure consists of a fixed jaw plate and a movable jaw plate. During operation, the motor drives the belt and eccentric shaft, causing the movable jaw to move back and forth periodically relative to the fixed jaw. When material enters the crushing chamber formed by the two jaw plates, it is crushed by a combination of compression, splitting, and bending. When the crushed material is smaller than the discharge opening, it is discharged under gravity, completing the crushing process.

PE jaw crusher structure diagram

II. Core Advantages and Features

After 20 years of technological accumulation, our jaw crushers possess the following significant advantages:

1. Robust and durable, with strong processing capacity: Using high-strength steel plate welded frames and heavy-duty eccentric shaft bearings, ensuring the stability and long service life of the equipment when crushing high-hardness stone. The crushing chamber is deep and has no dead zones, resulting in high feeding capacity and output.

2. Wide range of applicable materials: Designed specifically for the hardest rocks and concrete, it can easily handle various ores and rocks with compressive strength not exceeding 320MPa.

3. Flexible and adjustable discharge size: The discharge opening size can be easily adjusted through a wedge or shim adjustment device, thereby controlling the final product particle size to meet the crushing needs of different stages.

4. Simple maintenance and low operating costs: Simple structure, and core crushing components (such as jaw plates) are easy to replace. The optimized dynamic design reduces energy consumption, saving you long-term operating costs. 5. Intelligent and Safety Upgrades: Modern models can integrate automatic lubrication systems, tramp iron protection devices, and PLC control systems to achieve intelligent monitoring and safe operation, reducing unexpected downtime.

Stationary crushing production line

III. Application Scenarios and Typical Cases

Our jaw crushers have successfully served hundreds of projects worldwide:

Scenario 1: Large-scale Granite Aggregate Production Line

Material: Granite

Configuration: PE-1200×1500 large jaw crusher as the primary crusher.

Results: Stable hourly output of 800-1000 tons, low flaky and elongated particle content in the finished aggregate, excellent particle shape, fully meeting the material standards for highways and high-speed rail construction.

Scenario 2: Urban Construction Waste Resource Recycling Center

Material: Waste reinforced concrete, blocks

Configuration: HD series jaw crusher (reinforced type).

Results: Effectively separates concrete from rebar, the crushed recycled aggregate is clean and can be used to produce recycled bricks or road base materials, achieving resource recycling.

IV. Equipment Selection and Matching Recommendations

Choosing the right jaw crusher is crucial for the success of a production line. We recommend that customers consider the following aspects:

Material Characteristics: Hardness, moisture content, clay content, maximum feed size.

Capacity Requirements: Desired hourly or daily tonnage.

Finished Product Specifications: Required different particle size distributions.

Typically, the jaw crusher, as a primary crushing equipment, can be combined with the following equipment to form an efficient production line:

Secondary Crushing: Recommended to be paired with a cone crusher (for high-hardness rocks) or an impact crusher (for medium-low hardness rocks and construction waste) for medium and fine crushing.

Screening and Conveying: Equipped with vibrating screens and multi-layer belt conveyors to form a closed-loop or open-loop circulation system.

V. Frequently Asked Questions (FAQ)

Q1: How often do the jaw plates of a jaw crusher need to be replaced?

A1: The lifespan of the jaw plates depends on the hardness, abrasiveness, and production volume of the material being crushed. Typically, when crushing highly abrasive materials such as granite, the lifespan is several hundred to several thousand hours. We offer jaw plates made of various materials (such as high-manganese steel and alloy steel) to suit different working conditions.

Q2: Can the equipment handle clayey materials with high moisture content?

A2: For materials with high water and mud content, clogging may occur in the lower part of the crushing chamber. We can provide targeted chamber design and discharge opening adjustment solutions. Please specify your working conditions during the purchase process so that we can recommend the most suitable model.

Q3: Does the factory provide installation guidance and technical support?

A3: Yes. We provide detailed equipment foundation drawings, installation manuals, and operation and maintenance videos. We can also send experienced engineers to the site for installation guidance, commissioning, and operation training to ensure optimal equipment performance.

Q4: Is the supply of core components (such as bearings and jaw plates) guaranteed?

A4: We have a complete spare parts warehouse to ensure the supply of original spare parts for all equipment we manufacture. We provide prompt service to guarantee the continuity of our customers' production.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.