24x36 Jaw Crusher | 100-150 TPH Solution for Hard Rock Crushing

In hard rock mining and the design of large-scale stone production lines, the primary crushing stage is the choke point that determines the efficiency, stability, and operating costs of the entire production line. Choosing a high-performance, robust, and durable jaw crusher is the first step to success.

Recently, we received a precise inquiry from a customer requesting a 24x36 jaw crusher with a capacity of 100-150 tons per hour for primary crushing of hard rock. This requirement list is very typical and representative, clearly outlining the core requirements of medium to large-scale hard rock crushing projects. As a manufacturer with twenty years of technological experience, we will use this as an example to deeply analyze how to scientifically configure a powerful tool for hard rock crushing.

In-depth Requirement Analysis: The Stringent Challenges of Hard Rock Crushing

The customer's requirements clearly point to the primary crushing of hard rocks (such as granite, basalt, quartz, etc.). These rocks have high compressive strength and strong abrasiveness, placing extraordinary demands on the durability, power, and structure of the equipment. A capacity of 100-150 tons per hour means the equipment needs to operate stably under continuous high loads. Any design flaws or insufficient configuration can lead to insufficient capacity or frequent downtime.

Every detail of the customer's requirements list is crucial:

• Specification 24x36: This is the feed inlet size (inches), approximately 600x900mm, a classic model for handling medium-sized raw materials and achieving the target output.

• Material requirement Mn18 or Mn18Cr2: This directly reflects the customer's deep understanding of wear-resistant components. High-manganese chromium alloy is key to resisting the intense wear of hard rock.

• Long connecting rod stroke: This design increases the swing stroke of the moving jaw, improving the crushing ratio and output, representing an advanced design concept for efficient hard rock crushing.

Our solution overview: Born for Hard Rock

To address the above challenges, the PE-600×900 reinforced deep-cavity jaw crusher, which we recommend and manufacture, is tailor-made for such working conditions. It's not simply a standard product offering, but a comprehensive hard rock crushing solution, from core components to power matching.

Core Design and Performance Advantages

The advantages of this model are reflected in every detail of handling hard rock crushing:

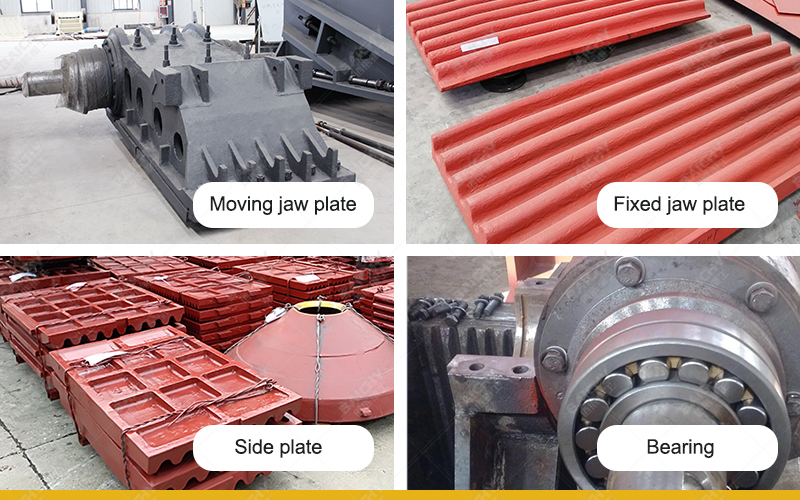

Wearing Parts Of PE600x900 Jaw Crusher

1. Exceptional Durability Core

◦ Jaw Plates: Strictly using customer-preferred Mn18Cr2 ultra-high manganese steel jaw plates. The addition of chromium refines the grain, enabling faster work hardening under severe impact. Its wear life is more than 30% longer than ordinary manganese steel, making it ideal for hard rock crushing.

◦ Heavy-duty Frame: An integral cast steel frame or high-strength welded frame, stress-relieved, ensures no deformation under continuous high-intensity impact, providing a rock-solid stable foundation for the entire machine.

2. Superior Structural and Dynamic Design

◦ Optimized Cavity Shape and Long Stroke: Adopting a V-shaped symmetrical deep cavity design, combined with customer-specified long connecting rods and a long stroke structure. This not only improves processing capacity and crushing ratio but also promotes laminar crushing, effectively reducing needle-like and flaky products and uniformly wearing down the jaw plates, extending their service life.

◦ Heavy-duty eccentric shaft: Forged from high-strength alloy steel, precision-machined and heat-treated, its load-bearing capacity far exceeds that of ordinary designs, ensuring absolute reliability under hard rock impact.

3. Powerful and stable power matching

◦ Standard configuration includes a 75-90kW high-efficiency energy-saving motor, providing ample and sufficient power reserves for hard rock crushing. The motor base is integrated with the main unit, making installation simple and minimizing operating vibration.

4. Comprehensive turnkey configuration

◦ We provide a complete set of equipment, including the main unit, motor, motor base, V-belt, and anchor bolts. The total weight of the equipment is approximately 15.5 tons, with a compact and robust structure and a packaging volume of approximately 30 cubic meters, facilitating sea transport and rapid on-site installation.

Stationary crushing production line

Classic Application Case

This model of equipment has been successfully applied in a large granite quarry in Southeast Asia. The project's initial feed size is ≤500mm, and the discharge size requirement is ≤150mm, used for feeding the downstream cone crusher. Our 24x36 jaw crusher, with its stable output of 100-150 tons/hour and the ultra-long service life of its Mn18Cr2 jaw plates, has won high recognition from the customer, becoming the backbone of the production line, operating continuously for over 8000 hours without major repairs.

Recommended Extended Equipment

For customers who have completed primary crushing, we recommend the following equipment to build an efficient medium and fine crushing production line:

• Secondary Crushing: HPT multi-cylinder hydraulic cone crusher, specifically designed for medium and fine crushing of hard rock, offering high output and excellent particle shape.

• Tertiary Crushing/Shaping: VSI vertical shaft impact crusher, used for sand making and aggregate shaping, increasing product added value.

• Feeding and Screening: Heavy-duty plate feeder, circular vibrating screen, etc., forming a complete closed-loop circulation system.

Frequently Asked Questions (FAQ)

Q1: Will this 24x36 jaw crusher have a higher capacity when processing other materials, such as limestone?

A1: Absolutely. When processing medium- to low-hardness materials like limestone, with the same discharge port settings, its capacity can easily be increased by 30%-50%, reaching 150-200 tons per hour or even higher. The equipment's durability and low failure rate advantages will be even more pronounced.

Q2: What is the approximate service life of the jaw plates (Mn18Cr2)?

A2: This depends on the specific abrasive index of the rock and the output. In typical granite crushing, the service life of a set of Mn18Cr2 jaw plates is typically between 60,000 and 100,000 tons of output. We recommend periodic reversal to maximize the use of its wear surface.

Q3: How long does it take from ordering to the equipment arriving at our port?

A3: The standard production cycle is approximately 25-30 working days. Including sea freight time (depending on the destination port, it usually takes 30-45 days to reach major ports), the total delivery cycle is typically around 60-75 days. For urgent projects, we can provide expedited production solutions.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!