Mobile Crushing Plant Solutions in Mexico

As a major mineral resource country in North America, Mexico has seen a continuous increase in demand for mobile crushing plants in recent years, particularly in mining and construction waste processing. Mobile crushing plants, with their flexibility, mobility, and rapid deployment, have become the preferred equipment for Mexican mining and infrastructure projects. Mexican customers prioritize relocation flexibility, processing capacity, and overall operating costs when selecting mobile crushing plants.

Core Advantages of Mobile Crushing Plants

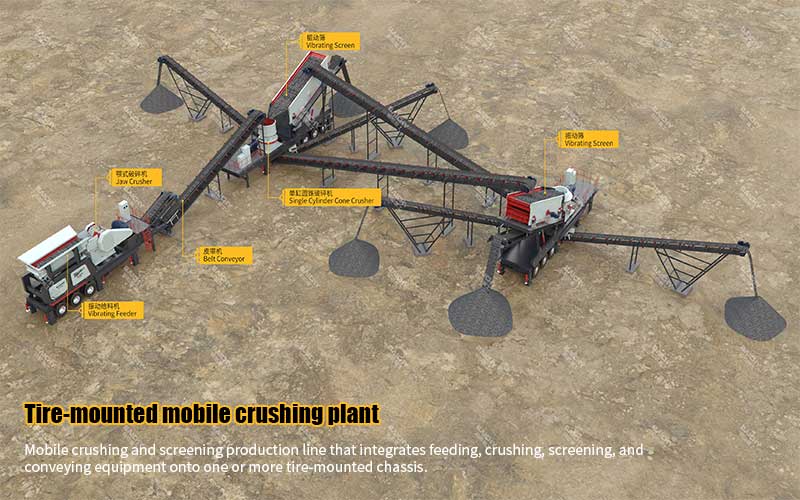

Integrated Design, Rapid Deployment

Mobile crushing plants integrate feeding, crushing, screening, and conveying functions into a single modular design, eliminating the need for complex infrastructure construction. Upon arrival, the equipment can be quickly put into operation via hydraulic support, significantly reducing site preparation time and material and labor consumption. The compact spatial layout enhances site adaptability, making it particularly suitable for space-constrained scenarios such as narrow construction sites and urban demolition sites.

High Mobility, Flexible Relocation

Mobile crushing plants are available in two main types: wheeled and tracked. Wheeled plants use a traction chassis with a small turning radius, allowing direct travel on ordinary roads, making them suitable for short to medium distance relocations and reducing transportation costs. The tracked type utilizes a fully rigid ship-shaped tracked chassis, resulting in low ground pressure and strong maneuverability. It can climb steep slopes up to 30° and adapt to harsh terrains such as mountains, mud, and wetlands, even turning on the spot, enabling it to travel even where there are no roads.

Reduced Overall Costs and Increased Efficiency

Mobile crushing plants follow the principle of local processing, eliminating the need for round-trip material transportation during on-site crushing, reducing transportation costs per ton of material by 30%-50%. The equipment employs an intelligent control system, enabling centralized operation and remote monitoring, reducing maintenance costs by 35% compared to traditional equipment. Furthermore, the equipment has a short investment payback period and strong asset preservation capabilities; after the project ends, it can be quickly deployed to new sites or sold for flexible asset realization.

Flexible Configuration and Strong Adaptability

Depending on the material hardness and finished product requirements, different main crushers can be flexibly configured, such as jaw crushers (coarse crushing), impact crushers (fine crushing of medium-soft materials), and cone crushers (medium-fine crushing of high-hardness materials). For construction waste processing, a dedicated iron separator can be added to separate reinforcing steel, meeting perse production needs.

Mexico Mobile Crushing Station Granite Crushing Site

Mexico Application Cases

Case 1: Mexican Iron Ore Project

The Tianjin Binhai Port Group's iron ore project in Mexico covers eight mining areas, geographically dispersed and spanning a large area. The project utilizes 16 mobile crushing stations (eight of each of two core models). The equipment requires no fixed installation and can flexibly move between mining areas, directly completing ore crushing operations on-site. The mobile crushing stations operate for up to 18 hours per day, continuously processing magnetite raw materials, ultimately producing finished ore with a size of 0-10mm, fully meeting subsequent production and processing requirements. This solution fundamentally eliminates the long-distance transportation of ore, significantly reducing transportation costs and time losses.

Case 2: Mexican Limestone Quarry

A limestone quarry uses the NKT150-4 four-unit mobile crushing station, designed with a capacity of 150 tons/hour. The equipment adopts a fully hydraulic folding structure, facilitating road transport. Upon arrival at the site, installation and commissioning can be completed within 24 hours, allowing for rapid production commencement. Targeting local working conditions, the equipment features enhanced wear resistance of core crushing components, an intelligent control system for centralized operation, and a centralized lubrication module to reduce daily maintenance. This ensures stable output quality while better meeting the comprehensive requirements of quarries for equipment mobility, reliability, and environmental performance.

Case Study 3: Mexican Construction Waste Treatment

A construction waste treatment project utilizes a mobile crushing station for on-site crushing and screening of waste concrete, bricks, and other construction waste. After processing, the waste concrete is transformed into recycled aggregates of different sizes (0-5mm, 5-10mm, 10-20mm) for use in road subbases and brick making. This project reduced construction waste transportation costs by over 30%, achieved an 80% recycling rate, and shortened the project duration by 20%, achieving a win-win situation for both economic and environmental benefits.

Equipment Selection Recommendation

Small Project Configuration (80-100tph)

Small Project Configuration (80-100tph)

A four-unit mobile crushing station is recommended, with a total installed power of approximately 280-350 kW. This configuration features an integrated design, with four modules integrated into a single chassis, eliminating the need for separate feeding and screening foundations, saving over 50% in infrastructure costs compared to traditional fixed production lines. The equipment comes with a tire/tracked chassis, allowing easy access to rural roads and scattered construction sites, reducing transportation costs by approximately 0.3 yuan per kilometer per ton of raw material. After arrival, the equipment can be connected and commissioned within 2-3 hours, shortening preparation time by 70% compared to traditional production lines.

Medium-sized project configuration (250-300 tph)

Medium-sized project configuration (250-300 tph)

A mobile station combining a jaw crusher and a cone crusher is recommended, with a total installed power estimated at 500-700 kW. This configuration is suitable for mines with a daily processing capacity of less than 5000 tons, reducing raw material transportation costs through on-site crushing and lowering overall costs by 25%-45%. The equipment can be commissioned and put into production within 3-5 hours of arrival, shortening the project preparation cycle. It can handle high-hardness materials and can also process construction waste through adjustments. Equipped with dust covers and dust collectors, it operates with low noise and meets environmental standards.

Large-Scale Project Configuration (500tph and above)

Large-Scale Project Configuration (500tph and above)

We recommend a combination of a semi-mobile crushing plant, a semi-autogenous mill, and an AI control system. The system monitors the crushing chamber status using vibration sensors and automatically adjusts the feeding speed, increasing equipment utilization by 18%. It is equipped with a long-distance belt conveyor system with a service life of 2-5 years, suitable for sand and gravel aggregate projects with an annual processing capacity exceeding 5 million tons. The steel structure support is bolted to standard components, allowing for complete relocation within 48 hours and reducing civil engineering work by 80%.

Frequently Asked Questions (FAQ)

Q1: What materials is a mobile crushing plant suitable for processing?

Mobile crushing plants can process a variety of materials, including limestone, granite, basalt, iron ore, construction waste, concrete blocks, and waste bricks. Different types of crushing units can be configured according to the material hardness: cone crushers for hard rock, impact crushers for medium-soft materials, and iron separators for construction waste.

Q2: How long does it take to relocate the equipment?

The relocation time for a tire-mounted mobile crushing plant is relatively short, generally 1-2 days to complete the relocation and put it into production. Tracked mobile crushing plants have a relatively long relocation time but are more adaptable to different terrains. Semi-mobile crushing plants adopt a modular design and can be completely relocated within 48 hours.

Q3: What are the precautions for daily maintenance?

Daily maintenance mainly includes: regularly checking for loose bolts in all parts; configuring power cables and control switches according to the equipment's power requirements; regularly lubricating bearings, gears, and other key components; paying attention to the wear degree of easily worn parts and replacing worn parts promptly; immediately stopping the machine and checking the cause if the bearing oil temperature rises. New equipment should be lubricated appropriately after 350 hours of operation; the main shaft bearing assembly should be opened for cleaning after 2000 hours; and the needle roller bearings should be replaced after 6500 hours.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!