In large-scale mining and aggregate production lines, 500t/h stationary crushing plantsare core equipment for handling high production demands. Choosing the right model directly impacts production efficiency, operating costs, and return on investment. This article systematically analyzes the key factors in selecting a 500t/h stationary crushing plant to help you make an informed decision.

1. Accurate Production Capacity Calculation

1.1 Verification of Theoretical Output

• Require suppliers to provide actual production data under similar material conditions

• Consider the impact of material hardness (Praeters hardness coefficient), moisture content, and mud content on production capacity

• It is recommended to reserve 10-15% of production capacity to cope with peak demand

1.2 Crushing Ratio Calculation

• Primary crushing (jaw crusher) recommended crushing ratio of 4-6

• Secondary crushing (cone crusher/impact crusher) crushing ratio of 3-5

• The overall crushing ratio must meet the requirements for feed size (e.g., 800mm) to finished product size (e.g., 0-31.5mm)

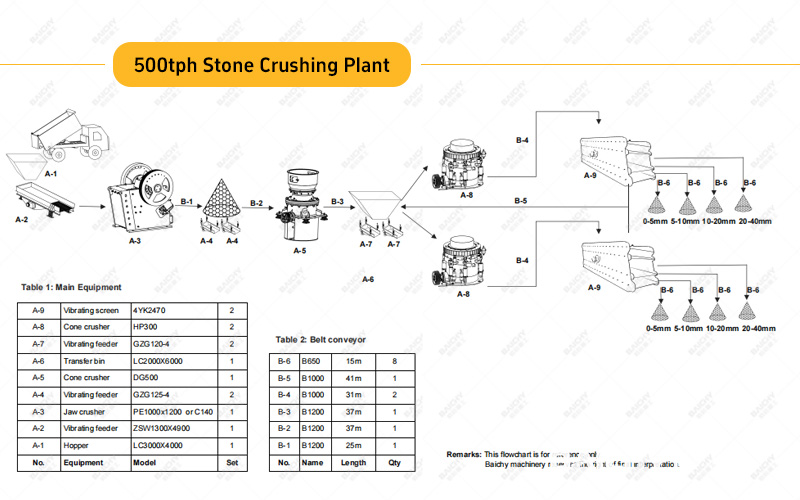

2. Equipment Configuration Selection

Comparison of Typical Configuration Options

| Configuration Options | Applicable Materials | Energy Consumption (kWh/t) | Finished Product Shape | Maintenance Cost |

| Jaw Crusher + Cone Crusher | High Hardness Rock | 1.8-2.2 | Cubic | Medium |

| Jaw Crusher + Impact Crusher | Medium-Low Hardness | 1.5-1.8 | Multi-Angular | Gyratory Crusher + Cone Crusher |

| Gyratory Crusher + Cone Crusher | Extra-Large Mine | 1.6-2.0 | excellent | High |

Key Equipment Selection Recommendations

• Primary crushing: Select a C-series jaw crusher (feed opening ≥ 800 x 1000mm)

• Secondary crushing: HP multi-cylinder hydraulic cone crusher (for highly abrasive materials) or CI-series impact crusher

• Screening Equipment: 3-4 decks of heavy-duty vibrating screens (screening efficiency ≥ 90%) are recommended.

3. Site Planning and Infrastructure Requirements

3.1 Key Site Layout

• Equipment Spacing: A 15-20 meter buffer zone is recommended between the jaw crusher and cone crusher.

• Stockpile Height: Buffer pile capacity before primary crushing ≥ 2 hours' output (approximately 1,000 tons).

• Conveyor Angle: Conveyor inclination ≤ 18° (≤ 15° for high-water content materials).

3.2 Infrastructure Standards

• Concrete Foundation Thickness: ≥ 2.5 meters for main equipment.

• Spring shock absorbers are required for vibrating equipment.

• Maintain a safe distance of at least 10 meters between the electrical room and the crushing area.

4. Energy Consumption and Operating Cost Analysis

4.1 Recommended Power Supply Configuration

• Total Installed Power: Approximately 800-1000 kW (including auxiliary equipment).

• Power Factor Compensation (cosφ ≥ 0.92) is recommended.

• Power consumption per ton of aggregate is controlled at 1.6-2.0 kWh.

4.2 Estimated Wear Parts Consumption

• Jaw plate life: Approximately 60,000-80,000 tons/set under granite conditions

• Cone crusher liner: 30,000-50,000 tons/set

Welding repair technology is recommended to extend service life by 30%

5. Intelligent and Environmentally Friendly Configurations

5.1 Intelligent Control System

• Required Functions: Automatic load adjustment, blockage warning, remote monitoring

• Recommended Configuration: Online particle size analyzer (can reduce over-crushing by 15%)

5.2 Environmental Compliance Plan

• Spray system: Water consumption 0.05-0.1 m³/ton of material

• Dust removal efficiency: ≥99% (pulse bag filter)

• Noise control: Overall ≤75 dB (using a soundproof enclosure + muffler)

6. Return on Investment Calculation

Economic Evaluation Parameters

• Equipment Investment: Approximately 8-12 million RMB (including auxiliary equipment)

Payback period: Approximately 2-3 years based on current aggregate prices.

• An LCC (Life Cycle Cost Analysis) analysis is recommended.

Selecting a 500-ton fixed crushing plant requires comprehensive consideration of multiple factors, including material characteristics, site conditions, investment budget, and environmental requirements.

For a customized selection plan or to schedule a site visit, please contact our technical team. We will provide a complete solution, including equipment configuration drawings, basic construction drawings, and an investment budget.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)