What is the maximum feed size range of Raymond Mill equipment?

The maximum feed size range of Raymond Mill is usually 15-30mm (1.5-3cm), but it depends on the equipment model and the manufacturer's design optimization. The feed size of most Raymond mills is ≤25mm (such as 3R/4R series), and some models with enhanced design can handle materials of ≤30mm.

Limiting factors:

- Gap between grinding roller and grinding ring: Too large feed can easily lead to blockage or reduced grinding efficiency.

- Main engine power: Large-size feed requires higher power drive, which may increase energy consumption.

Raymond mill itself cannot directly handle 30cm raw materials, and usually needs to be matched with primary crushing equipment such as jaw crusher and hammer crusher.

YGM series high pressure grinding mill comparison table

| Parameters | YGM95 | YGM130 | YGM160 |

| Maximum feed size | ≤30mm | ≤35mm | ≤40mm |

| Capacity range | 15-35 tons/day (gypsum powder) | 30-60 tons/day | 50-100 tons/day |

| Finished product fineness | 80-425 mesh | 80-425 mesh | 80-425 mesh |

| Main motor power | 90kW | 160kW | 220kW |

| Number of grinding rollers | 4 | 5 | 6 |

| Grinding roller diameter | 310mm | 410mm | 470mm |

| Equipment weight | ~12 tons | ~18 tons | ~25 tons |

| Applicable materials | Gypsum, limestone, calcite | Gypsum, barite, fluorite |

High-hardness ores (such as marble) |

Raymond mill equipment selection recommendations

1. YGM95 (economical and practical)

Recommended scenarios:

- Daily output of gypsum powder 20-30 tons (need to run close to the upper limit).

- Raw material size ≤30mm, general power infrastructure (90kW motor adapts to common industrial voltage in Libya).

Advantages:

- Low investment cost, simple maintenance, suitable for start-ups or small government reconstruction projects.

2. YGM130 (balanced high-yield type)

Recommended scenarios:

- Daily output of gypsum powder 30-60 tons, need to take into account future capacity expansion.

- The raw material contains a small amount of impurities (such as clay associated with gypsum ore), which requires stronger grinding force.

Advantages:

- Larger feed (≤35mm), reducing pre-crushing pressure;

- The grinding roller has stronger pressure and more stable powder fineness.

3. YGM160 (large industrial grade)

Recommended scenarios:

- Daily output of gypsum powder more than 50 tons, or processing high-hardness ores (such as gypsum containing quartz sand in some areas of Libya).

- Supporting stable industrial power grid (220kW high power consumption).

Advantages:

- Ultra-high production capacity, suitable for building materials groups or export-oriented powder processing plants;

- Extremely durable, but requires a professional operation and maintenance team.

Things to note for the Libyan market

1. Power matching:

- YGM95 (90kW) can be adapted to diesel generator backup, and YGM130/160 needs to ensure the stability of the factory's three-phase power.

2. Raw material pretreatment:

- If the size of gypsum raw material is greater than 40mm, a jaw crusher + impact crusher (such as PE600×900 + PF1214) is required.

3. After-sales response:

- It is recommended to equip YGM130/160 with a local technical agent and reserve grinding rollers, bearings and other wearing parts.

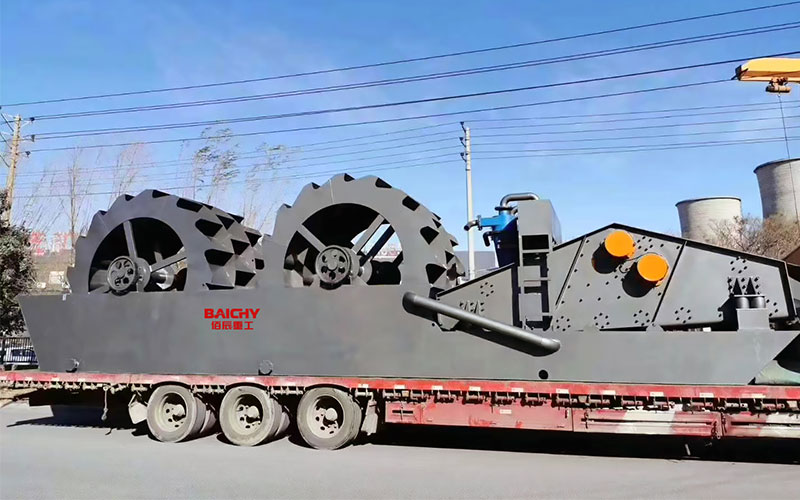

Why choose Baichy Heavy Industry?

1. Deep technical accumulation, industry leading

● 20 years of R&D experience: Focus on deep technology in the field of mining machinery, and accumulate rich industry insights and solutions.

● 56 patented technologies: Covering key links such as equipment design and production process, reflecting continuous innovation capabilities and technical barriers.

● Market-proven star products: PFL series equipment has sold more than 5,000 units worldwide, with stable and reliable performance to meet diversified production needs.

2. Guaranteed service, worry-free for customers

① Extremely fast response mechanism:

● Engineers provide 7×24-hour online technical support to solve emergencies as soon as possible.

● Any site in the world within 48 hours to minimize losses.

②Long-term cost advantage:

● Core components are guaranteed for one year to reduce the maintenance cost of young people.

● Accessories are supplied at cost price for life to eliminate the problem of price compensation for late replacement.

3. Globalization, adapting to extreme working conditions

● Covering 150+ countries and regions: including Southeast Asia, Africa, South America and other markets, the verification equipment is widely applicable.

● Extreme environment test: It can still operate stably under groundwater conditions such as high temperature, high humidity, and high special zone, and has strong technical reliability.

4. Full-cycle service support to help efficient operation

● From installation to training: Provide professional on-site guidance installation and worker operation training to ensure rapid production of equipment.

● After-sales system: Improve maintenance, technical upgrade support, long-term operation of efficient equipment, and extend service life.

● Rights protection: Directly connect through official channels (official website: http:www.baichychina.com/WhatsApp:+86 15093222637) to avoid intermediate risks and enjoy genuine services.