Choosing a suitable secondary crusher requires comprehensive consideration of factors such as material properties, production requirements, equipment performance, and economy. The following is a detailed selection guide from Baichy Heavy Industry, I hope it can help you.

1. Clarify the characteristics of the crushed material

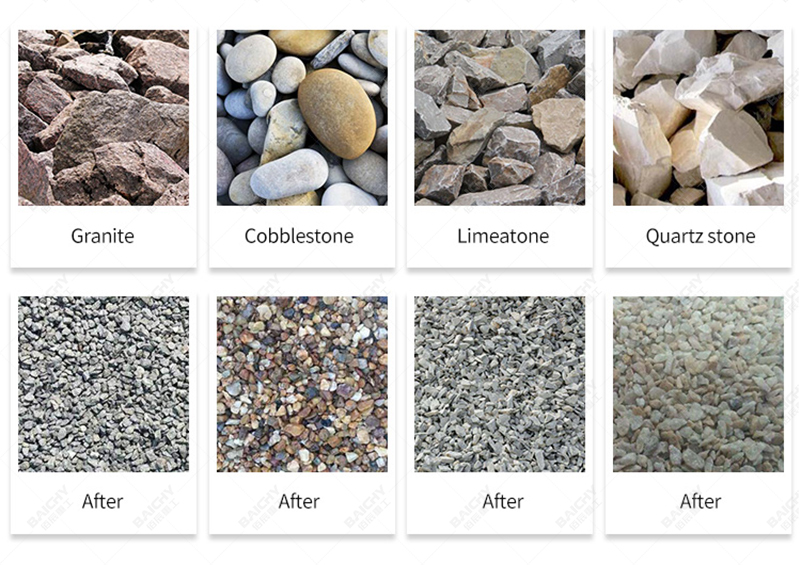

• Hardness and wear resistance: High-hardness materials (such as granite) require equipment with strong wear resistance (such as a cone crusher); medium and low hardness (limestone) can choose an impact crusher or hammer crusher.

• Particle size requirements: If fine crushing (≤30mm) is required, an impact crusher or a vertical shaft impact crusher is preferred; if medium particle size (30-100mm) is required, a cone crusher or hammer crusher is more suitable.

• Moisture content and viscosity: Wet and sticky materials are prone to clogging, so you need to choose equipment with grates or impact plates (such as an impact crusher) and avoid using a jaw crusher or a cone crusher.

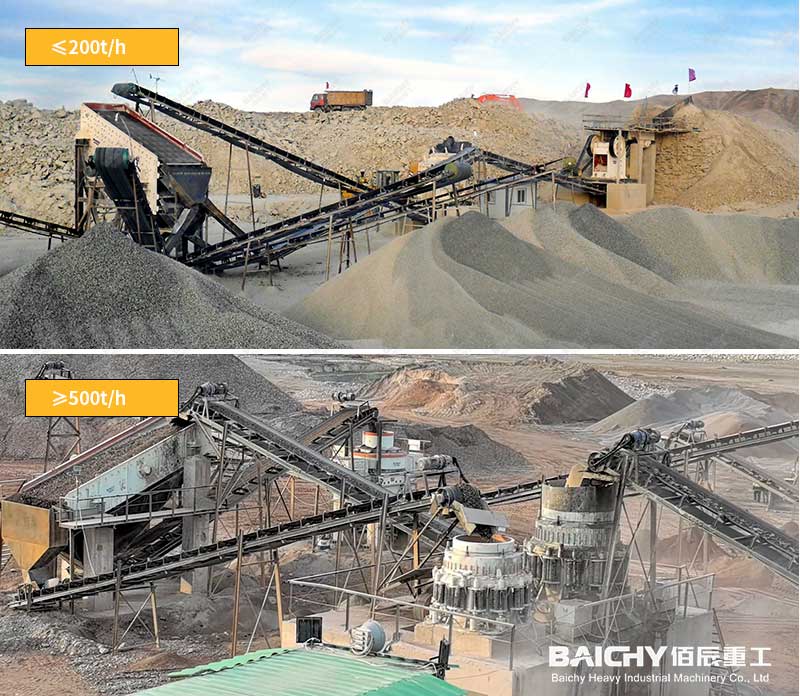

2. Match production needs

• Capacity requirements: For small and medium-sized production capacities (≤200t/h), an impact crusher or hammer crusher can be selected; for large production lines (≥500t/h), a cone crusher or a multi-machine combination is recommended.

• Finished product shape: When cubic particles (such as aggregates) are required, an impact crusher or a vertical shaft impact crusher is better; when the particle shape requirements are not high, a cone crusher can be selected.

• Flexibility: Mobile crusher is suitable for multi-site operations, and the fixed type is suitable for long-term stable production.

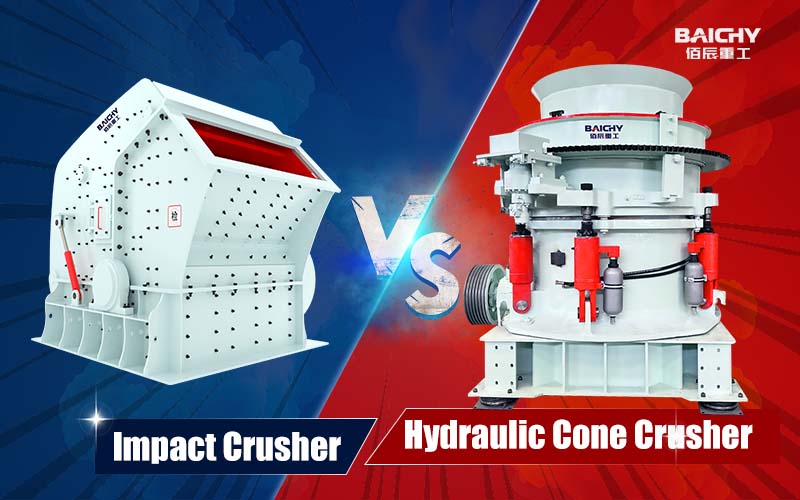

3. Equipment type comparison

| Type | Applicable materials | Discharge size | Capacity range | Advantages and disadvantages |

| Impact crusher | Medium-low hardness, brittleness | 5-60mm | 50-500t/h | Good particle shape, but short life of wear-resistant parts |

| Cone crusher | High hardness, strong abrasiveness | 10-100mm | 100-1000t/h | Wear-resistant, high energy consumption, complex maintenance |

| Hammer crusher | Medium-low hardness, brittleness | 5-20mm | 50-300t/h | Simple structure, but the hammer head wears quickly |

| Vertical shaft impact crusher | Medium-high hardness, sand making | ≤5mm | 60-400t/h | Excellent particle shape, suitable for machine-made sand |

4. Key performance parameters

• Feed size: Ensure that the maximum feed size of the equipment is ≥ the maximum size of the material (e.g., the feed port of the impact crusher needs to be ≥500mm).

• Motor power: High-hardness materials require higher power (e.g., a cone crusher of 200t/h needs more than 200 kW).

• Speed and rotor diameter: The rotor speed of the impact crusher directly affects the crushing efficiency (usually 20-40m/s).

5. Economic efficiency and maintenance cost

• Initial investment: Cone crusher > impact crusher > hammer crusher, but cone crusher is more economical under long-term high production capacity.

• Replacement of wear-resistant parts: The life of the plate hammer of the impact crusher is about 200-500 hours, and the mortar wall of the cone crusher can reach more than 1000 hours.

• Energy consumption comparison: The power consumption per ton of cone crusher is 10-30% higher than that of the impact crusher.

6. Site conditions

• Installation space: Cone crusher requires larger infrastructure, while mobile impact crusher occupies smaller space.

• Environmental protection requirements: Closed design (such as a vertical shaft crusher) can reduce dust, and noise must be controlled below 85 dB.

7. Recommended selection process

• Sampling test: Conduct material crushing work index (Bond index) and abrasiveness test.

• Simulated production: Verify the discharge effect through the equipment manufacturer's test machine.

• Comparison plan: Calculate the total cost for 3-5 years (including energy consumption, maintenance, and capacity loss).

• Customized plan: Requires the manufacturer to adjust the design for special needs (such as high soil content).

Example selection

Granite sand making (100t/h): HP300 cone crusher (coarse crushing) + VSI1140 vertical shaft impact crusher (sand making).

Limestone secondary crushing (200t/h): PFW1313 impact crusher, discharge ≤30mm, equipped with soil removal screening.