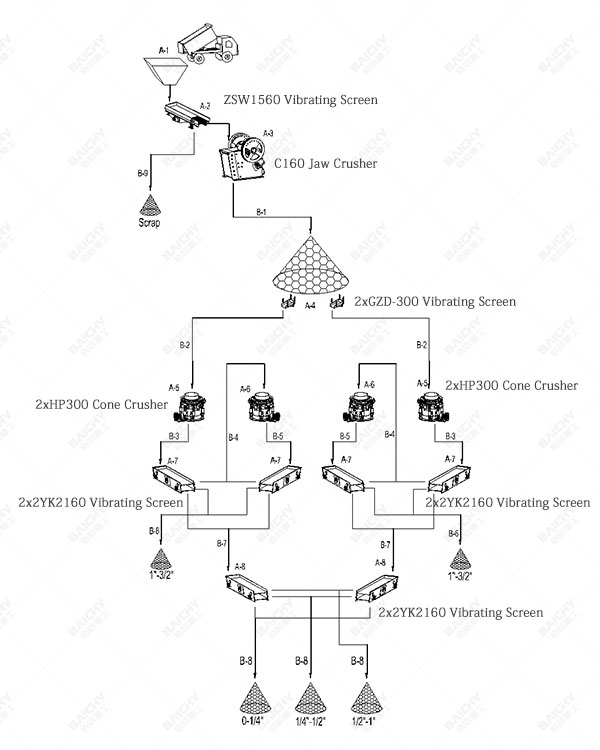

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW1500X6000 | 1 |

| A-3 | Jaw Crusher | C160 | 1 |

| A-4 | Vibrating Feeder | GZG-300 | 2 |

| A-5 | Cone Crusher | HP300 | 2 |

| A-6 | Cone Crusher | HP300 | 2 |

| A-7 | Vibrating Screen | 2YK2160 | 4 |

| A-8 | Vibrating Screen | 2YK2160 | 2 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B1400 | 35m | 1 |

| B-2 | B1000 | (28+8)m | 2 |

| B-3 | B1000 | 21m | 2 |

| B-4 | B800 | (23+8)m | 2 |

| B-5 | B800 | 21m | 2 |

| B-6 | B800 | (25+8)m | 2 |

| B-7 | B800 | 21m | 2 |

| B-8 | B650 | (25+8)m | 3 |

| B-9 | B650 | 20m | 1 |

For large-scale aggregate production needs, we have designed an intelligent rock crushing solution with a capacity of 500-600 tons/hour. This system integrates high-efficiency crushing, intelligent control, and environmental protection with low noise, meeting the processing requirements of various hard rocks (granite, basalt, limestone, etc.) and ensuring the production of high-quality aggregates.

• Adopting HP300 cone crusher and laminated crushing technology, energy consumption is reduced by 30%, which is more power-saving than traditional equipment.

• Automated control system, real-time monitoring of equipment operation status, and reduction of manual intervention.

• Two-stage cone crusher (medium crushing + fine crushing) optimizes aggregate particle shape, reduces needle-like content, and meets Class I aggregate standards.

• C160 jaw crusher + HP300 cone crusher combination, suitable for high-hardness rock (compressive strength ≤350MPa).

• Four 2YK2160 vibrating screens in parallel, high screening efficiency, reducing the risk of blockage.

• Fully enclosed steel structure design, equipped with pulse dust removal system, dust emission ≤20mg/m³.

• Low-noise vibration equipment, factory boundary noise ≤75dB, in line with environmental protection requirements.

Applicable rock types: granite, basalt, diabase, quartz stone and other high-hardness ores.

• 0-5mm (machine-made sand, used for concrete, dry mortar)

• 5-10mm (fine aggregate, used for prefabricated components)

• 10-20mm (medium aggregate, used for commercial concrete stations)

• 20-31.5mm (coarse aggregate, used for roadbed, asphalt concrete)

• Capacity: 550 t/h

• Equipment configuration: C160 jaw crusher + 4 HP300 cone crushers + 4 2YK2160 vibrating screens

• Finished product use: Supply local infrastructure projects, with stable aggregate gradation and high customer satisfaction.

• Capacity: 600 t/h

• Environmental protection measures: fully enclosed + dust removal system, passed environmental assessment acceptance.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!