1100/1200 Model Gold Grinding Mill Manufacturer Exporting to Egypt

Why Do Egyptian Markets Favor 1100 and 1200 Model Gold Grinding Mills?

In recent years, Egypt, leveraging its abundant gold resources, has been actively developing its domestic mining industry. Against this backdrop, efficient, reliable, and easy-to-operate mineral processing equipment has become the preferred choice for local mining companies. The 1100 and 1200 model gold grinding mills, as the golden core of medium-sized gold processing plants, perfectly meet the needs of most small and medium-sized gold mining projects in Egypt. Their moderate processing capacity, short return on investment period, and strong adaptability to complex ores are key factors in their success in the Egyptian market.

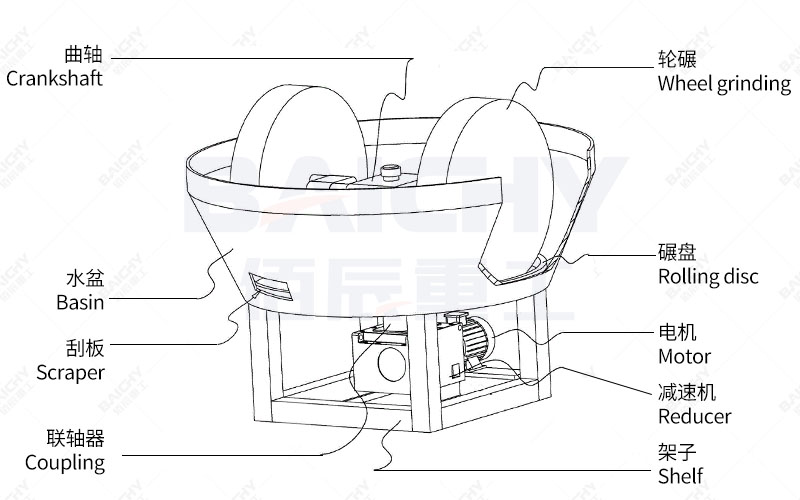

Gold grinding machine structural diagram

A Classic and Reliable Gold Extraction Tool

The gold grinding mill, also known as a wet grinding mill or roller mill, is a core piece of equipment in the amalgamation gold extraction method. It uses heavy rollers rotating on a grinding plate to crush, grind, and stir the ore, allowing gold particles to be fully concentrated in the mercury amalgam. Our 1100 and 1200 models inherit the reliability of traditional designs and incorporate modern manufacturing processes, making them highly efficient mineral processing equipment proven in numerous gold mining projects worldwide.

Excellent Performance Crafted with 20 Years of Expertise

1. Robust Structure, Durable and Long-lasting: Manufactured with thickened steel plates and heavy-duty castings, key components undergo special heat treatment, ensuring long-term stable operation under harsh working conditions and significantly reducing maintenance costs.

2. Thorough Grinding, High Recovery Rate: The unique grinding plate and roller design ensure thorough crushing and grinding of the ore, maximizing the exposure of gold particles and their combination with mercury, significantly improving the gold recovery rate.

3. Simple Operation, Convenient Maintenance: User-friendly design and stable operation allow ordinary workers to operate the machine after simple training. Modular design makes daily maintenance and replacement of wear parts easier and faster.

4. Strong Adaptability, Fast Return on Investment: Effective not only for primary ores but also for oxidized ores and placer gold deposits. The reasonable equipment investment cost helps customers quickly achieve a return on their investment.

Our Gold Grinding Mills in Egypt

Our Gold Grinding Mills in Egypt

In 2023, we partnered with a gold mining company in the Aswan region of Egypt. The company previously used outdated equipment, resulting in low recovery rates and frequent breakdowns. After evaluating several suppliers, they ultimately selected our 1200 model gold grinding mill. After installation and commissioning, the equipment operated extremely stably, increasing gold recovery rates by approximately 15%, while significantly reducing energy consumption and downtime for maintenance. The customer highly praised the quality of our gold grinding mill and our professional after-sales support, and has already planned to purchase an additional 1100 model for their new pilot production line.

Building a Complete Gold Processing Production Line

An efficient gold grinding mill needs to work in conjunction with upstream and downstream equipment to achieve maximum efficiency. As a one-stop manufacturer of mineral processing equipment, we can also provide you with:

• Crushing equipment: Jaw crushers, roller crushers, to prepare raw materials with suitable particle size for grinding.

• Grinding equipment: Ball mills, for processes requiring finer grinding particle sizes.

• Classification and separation equipment: Spiral classifiers, shaking tables, centrifugal gold concentrators, for other mineral processing methods or comprehensive recovery.

• Auxiliary equipment: Feeders, mixing tanks, dust collectors, etc.

Frequently Asked Questions (FAQ)

1. What are the main differences between the 1100 and 1200 models?

The main differences are in processing capacity and dimensions. The 1200 model has a larger grinding disc diameter and roller weight, and its hourly ore processing capacity is approximately 20-30% higher than the 1100 model, making it suitable for slightly larger processing plants. Customers can choose based on their daily ore processing volume and investment budget.

2. If the equipment is exported to Egypt, what support can you provide?

We provide comprehensive export services, including: packaging and sea freight that meet international standards, clear and easy-to-understand English installation manuals and operation videos, a package of key wear parts, and online remote debugging guidance and on-site engineer installation and commissioning services (optional). We ensure that the equipment can be successfully put into production upon arrival at your site.

3. Besides amalgamation, can the gold grinding mill be used for other purposes?

Yes. Besides gold extraction, grinding mills are also commonly used for grinding and amalgamation of rare metal ores such as silver, lead, and zinc. They are also used as efficient wet mixing and grinding equipment in some chemical and building materials industries.

Choosing a reliable grinding mill is the first step to successful gold mining investment. With our extensive technical expertise and deep understanding of global mining needs, we ensure that every piece of equipment we export embodies the reliability and efficiency of Made in China. If you are looking for a trustworthy mining equipment partner in Egypt or other parts of the world, we are ready to provide you with professional solutions.

About of Baichy Heavy Industry

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)

Further reading:

How To Reduce The Energy Consumption Of Ball Mill? 5 Practical Energy-Saving Tips

Iron Ore Beneficiation Process: Magnetic Separation/Flotation/Gravity Separation