10tph full gypsum processing line

With the rapid development of infrastructure construction and urbanization in Ethiopia, the local building materials market has an increasingly strong demand for high-quality gypsum powder. As a manufacturer of mining crushing and grinding equipment with 20 years of professional experience, we deeply understand the market pain points and have successfully designed and delivered a highly efficient and stable 10-ton/hour full gypsum processing production line for our Ethiopian clients. This article will delve into the core advantages and application value of this production line, providing professional reference for clients interested in investing in the Ethiopian gypsum industry.

I. Project Background and Market Analysis

Ethiopia possesses abundant natural gypsum mineral resources, providing a solid foundation for the development of its local gypsum building materials industry. However, traditional processing methods often suffer from low efficiency, substandard product particle size, and serious pollution, failing to meet the high-quality, high-volume demands of modern construction for gypsum products (such as gypsum board, gypsum putty, and mold plaster).

Therefore, introducing an automated, large-scale gypsum processing production line has become key to unlocking the potential of the local market. Our 10-ton/hour gypsum processing production line is tailor-made for clients with medium-sized investments seeking high returns. It can stably and continuously process raw ore into gypsum powder of various finenesses that meet market standards.

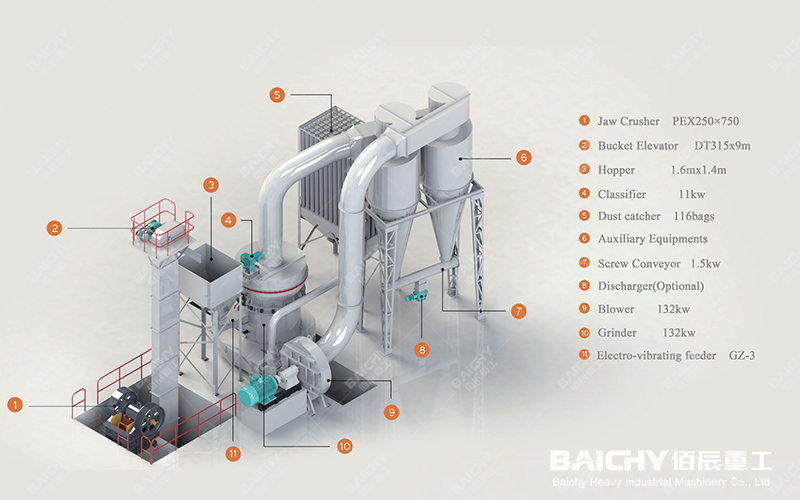

Flow chart of grinding production line

II. Overview of Core Process Flow of the Production Line

Our gypsum processing production line adopts an integrated design of "crushing-grinding-calcination-modification," ensuring full controllability from raw materials to finished products.

1. Coarse Crushing and Pre-homogenization

Large pieces of natural gypsum ore are first primary crushed by a jaw crusher to a size of less than 100mm, facilitating subsequent conveying and homogenization, and ensuring the stability of the raw material entering the mill.

2. Fine Grinding and Drying

The coarsely crushed gypsum blocks are fed into a hopper by a bucket elevator and then evenly fed into a Raymond mill or vertical mill via a feeder. Inside the grinding chamber, the gypsum is crushed and ground by grinding rollers, while hot air is introduced, achieving simultaneous grinding and drying, effectively reducing material moisture and improving grinding efficiency.

3. Calcination and Cooling

The ground gypsum powder is fed into a fluidized bed furnace or rotary kiln for calcination, removing some of the water of crystallization and transforming it into building gypsum (calcined gypsum). The calcined gypsum is then cooled by a high-efficiency cooler to stabilize its physical properties.

4. Finished Product Collection and Storage

The calcined and cooled finished gypsum powder is conveyed to the finished product silo by an airflow system. It can be equipped with an automatic packaging machine or a bulk delivery system as needed to complete the final stage of the production line.

III. Core Advantages of the Production Line

• High Cost-Effectiveness and Adaptability: The 10-ton/hour capacity design perfectly matches the market demand of medium-sized projects in Ethiopia and surrounding areas, with a moderate investment scale and a reasonable payback period.

• High Efficiency and Energy Saving: Utilizing our optimized grinding and calcination system, energy consumption is reduced by approximately 15-20% compared to traditional equipment, significantly reducing long-term operating costs for customers.

• Superior Finished Product Quality: The production line is equipped with a highly efficient grading system, allowing for flexible adjustment of the fineness of the finished gypsum powder between 80-325 mesh. The particle size distribution is reasonable, and the powder has high activity, fully meeting the standards for high-quality building materials production.

• Stable and Reliable Operation: Core equipment such as the crusher, mill, and calcining furnace are manufactured using mature processes accumulated over 20 years, ensuring long-term stable operation and a low failure rate under Ethiopian working conditions.

• Environmental Compliance: The entire line adopts negative pressure production and is equipped with a pulse bag filter. Dust emissions are far below international environmental standards, achieving green production.

Grinding production line customer site

IV. Success Story Sharing

Our client in Oromia State, Ethiopia, introduced this 10-ton/hour all-gypsum processing production line in 2023. The client's primary goal is to supply raw materials to gypsum board factories in Addis Ababa and surrounding cities. Since its commissioning, the production line has operated smoothly, consistently achieving its designed production capacity. The purity and fineness of the produced gypsum powder have been highly recognized by downstream customers, helping them quickly capture regional market share and achieve significant economic benefits.

V. Recommended Equipment

• PE Series Jaw Crusher: As the "pioneer" of the production line, it processes large gypsum ore with its robust structure and high crushing ratio.

• MTW European-style Grinding Mill: The core grinding equipment, with high output, low energy consumption, and uniform finished product fineness, ensuring high-quality gypsum powder production.

• Gypsum Fluidized Bed Calcining Furnace: Provides uniform calcination and high thermal efficiency, allowing precise control of the gypsum phase composition and improving product performance.

VI. Frequently Asked Questions (FAQ)

1. What are the requirements for the plant and infrastructure of this production line?

A: We will provide complete plant layout and basic drawings in the early stages of the project. Generally, a factory space with a height of approximately 15-20 meters is required, along with a stable power supply (specific power depends on configuration) and a reliable water source for equipment cooling (recycled). Our engineers will provide full guidance throughout the process.

2. How long does it take from installation to commissioning?

A: Ideally, under the condition that equipment and civil engineering proceed smoothly in tandem, it typically takes 2-3 months from equipment arrival on site to completion of installation and commissioning. Our professional team will provide full installation guidance and worker training services.

3. Is the supply and replacement of vulnerable parts convenient?

A: We have established a central spare parts warehouse for our global clients. For Ethiopian clients, we are committed to providing long-term supply support for key vulnerable parts and provide clear replacement instructions. Standard parts can usually be delivered within 3-4 weeks via sea freight.

Investing in a stable and efficient gypsum processing production line is a wise move to seize opportunities in Ethiopia's booming building materials market. With 20 years of professional experience, we ensure that we deliver not just equipment, but a complete production solution and sustained value returns. We look forward to partnering with you to unlock Ethiopia's gypsum wealth.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!