Vibrating Grizzly Feeders | Classification & Separation

Before crushing, screening, and mineral processing, efficient and uniform feeding, and the initial grading and separation of materials, are crucial first steps in improving overall efficiency and finished product quality. This article will delve into the outstanding application of vibrating bar feeders in this core process.

I. In-depth Analysis: Why a Vibrating Bar Feeder?

In industries such as mining, quarrying, building materials, and metallurgy, the materials from blasted ore to the next process are typically complex in composition, uneven in particle size, and may contain impurities such as mud. Traditional feeding methods (such as plate feeders) can only perform the conveying function and cannot pre-process the materials.

Vibrating bar feeders cleverly combine the functions of vibrating feeding and bar screening. Its core principle lies in using a powerful vibrating motor to drive the material in the trough, causing it to continuously jump forward. During this movement, fine materials smaller than the grid gaps (such as qualified particle size products or soil) are separated in advance and fall directly into the lower conveyor belt or hopper, while larger materials continue to be conveyed along the grid surface to the crusher. This design achieves a three-in-one system of feeding, screening, and coarse separation.

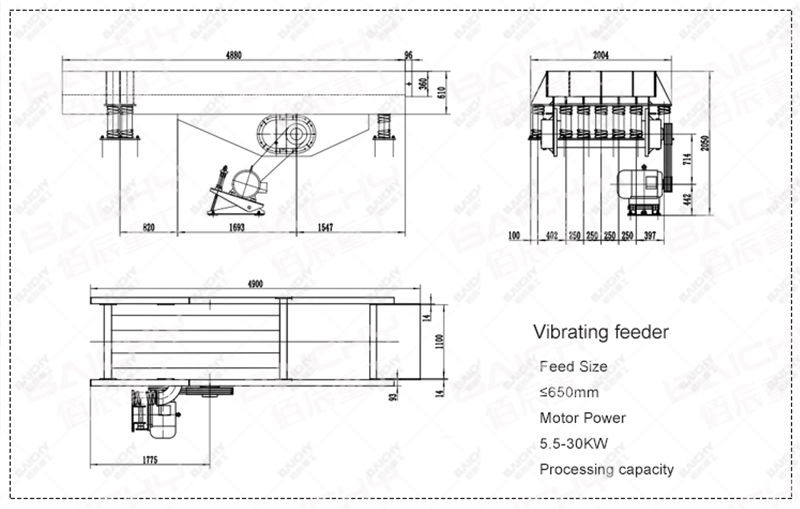

Vibrating feeder outline drawing

II. Equipment Overview and Working Principle

1. Core Structural Components

A typical vibrating grid feeder mainly consists of the following parts:

• Vibrating Motor: Serves as the power source, generating high-frequency linear vibration.

• Grid Trough: Made of wear-resistant steel plate, with the bottom of the trough covered with a grid cut from wear-resistant steel bars or plates. The gaps can be customized according to process requirements.

• Shock Absorbing Springs: Support the entire equipment and isolate the vibration force transmitted to the base frame.

• Frame Base: Provides stable support for the equipment.

2. Workflow Overview

Material enters the feeder trough from the silo or stockpile → Under the directional excitation force generated by the vibrating motor, the material is thrown up and moves forward in a parabolic motion → During this motion, fine particles fall through the gaps in the grid → Larger pieces and qualified materials are conveyed to the discharge end of the equipment for the next process (usually a jaw crusher).

III. Significant Advantages of Choosing a Vibrating Bar Feeder

• Pre-treatment, improved efficiency: Pre-screening removes soil and fine materials, reducing the burden on the primary crusher, preventing material blockage, and effectively increasing the processing capacity of subsequent crushing systems by 20%-30%.

• Dual-purpose, cost-effective: One machine replaces both the traditional feeder and the pre-screening machine, saving on equipment purchase costs, installation space, and power consumption.

• Uniform feeding, stable operation: Vibrating feeder ensures continuous, uniform, and controllable feeding of material into the crusher, helping to maintain the fullness of the crushing chamber, protecting the equipment, and producing more uniform crushed products.

• Wear-resistant and durable with a long service life: Key contact parts (such as the grid and trough bottom) are made of high-strength wear-resistant steel plates or replaceable wear-resistant liners, adapting to harsh mining conditions and ensuring a long service life.

• Flexible customization and strong adaptability: The grid gap, trough size, inclination angle, vibration intensity, etc., can all be customized according to your material characteristics (particle size, moisture content, specific gravity) and output requirements.

Vibrating feeder on-site operation diagram

IV. Successful Application Cases

A large granite quarry successfully implemented a ZF-1560 vibrating grid feeder. In the customer's original process, the raw material had a high soil content, which caused frequent blockages and low efficiency when directly fed into the jaw crusher.

• Solution: We installed a vibrating grid feeder with a grid gap of 80mm under the raw material silo.

• Operational results: Approximately 30% of the soil and fine stone chips were separated in advance, the jaw crusher no longer experienced blockages, and the hourly throughput increased from 180 tons to 230 tons. Simultaneously, the separated fine material was sold as a by-product, bringing additional economic benefits to the customer. The equipment has been operating stably for over 3 years and has received high praise from customers.

V. Recommended Related Equipment

To build an efficient and continuous primary crushing production line, we generally recommend using the vibrating bar feeder in conjunction with the following equipment:

1. Heavy-duty jaw crusher: Receives large pieces of material after preliminary screening for coarse crushing.

2. Belt conveyor: Used to transport undersize material and crushed material.

3. Magnetic separator: Can be installed above the feeder or the discharge belt to remove iron pieces from the raw material, protecting downstream crushing equipment.

VI. Frequently Asked Questions (FAQ)

1. Is a vibrating bar feeder suitable for handling sticky materials?

For highly sticky soil or materials with high clay content, bar clogging may occur. In this case, we recommend using a bar feeder, which has larger gaps between the bars and a certain self-cleaning ability under vibration, resulting in better anti-clogging performance. Specific testing and analysis based on material samples are required.

2. Can the bar gap be adjusted?

The grid gap is determined and fixed according to your process requirements during equipment manufacturing. It is generally not adjustable afterward. However, we can offer a quick-change grid design, allowing you to adapt to different future production requirements by replacing grid modules with different gaps, providing greater flexibility.

3. Is equipment maintenance complex?

Maintenance is very simple. The main tasks focus on periodically checking the tightness of the vibration motor bolts, the lubrication oil condition, and inspecting the wear of the wear-resistant liners and grid. Daily maintenance simply requires keeping the equipment operating area clean and free of accumulated material obstructing vibration.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!