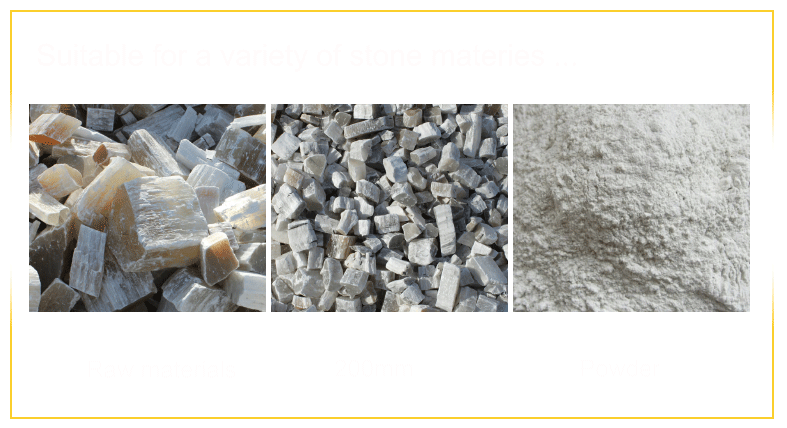

Ideal Choice For Tanzanite Gypsum Powder Processing

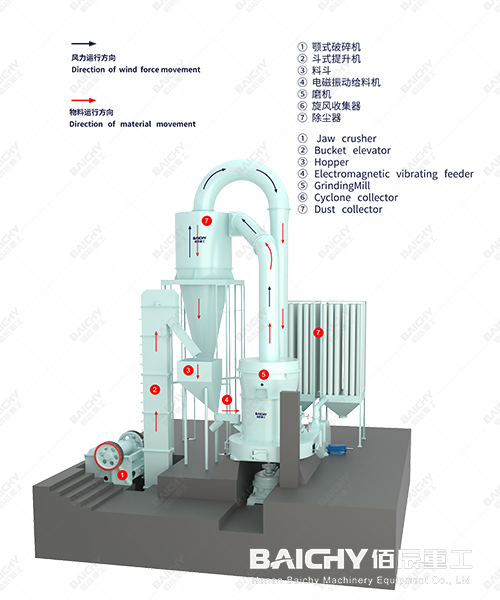

In the field of gypsum powder processing, Tanzanite gypsum is widely used in building materials, medical, food, and other industries due to its unique physical and chemical properties. To meet the needs of small and medium-sized production, the YGM95

high-pressure suspension roller mill is specially designed for Tanzanite gypsum powder processing, with a stable production capacity of 2-4 tons/hour and an adjustable finished product fineness of 80-325 mesh, helping enterprises to efficiently produce high-quality gypsum powder.

Core Advantages Of YGM95 Tanzanite Gypsum Powder Grinding Line

1. High efficiency and energy saving, reducing production costs

2. Adjustable finished product fineness, suitable for a variety of applications

3. Durable equipment and convenient maintenance

4. Factory direct sales, providing all-around support

Why Choose Our YGM95 Gypsum Powder Grinding Line?

✔ Professional team: 10+ years of experience in gypsum powder equipment manufacturing, providing free technical consultation.

✔ High cost performance: Factory direct sales, no middleman price difference, reducing procurement costs.

✔ Global service: Support customized production, installation and commissioning, and technical training to ensure efficient operation of equipment.