Sand and gravel aggregates are widely used in various construction fields such as water conservancy and hydropower, construction, bridges, and highways. The quality of aggregate directly affects the strength of concrete. What determines the quality of sand and gravel aggregates? How to improve the quality of sand and gravel aggregate? What kind of sand and gravel aggregate production equipment is used? Today, Baichy is here to give you a detailed introduction.

1. What are the factors that affect the quality of sand and gravel aggregates?

The quality of sand aggregate is directly related to the properties of the processed rock, equipment, and processing technology.

Different rocks have different physical and chemical properties, and they also differ in specific gravity, porosity, compressive strength, and tensile strength. At the same time, rocks of different properties have different choices of equipment and processes.

2. What are the sand and gravel aggregate production equipment?

The equipment required for the production of sand and gravel aggregates includes feeders, vibrating screens, crushers, sand-making machines, and conveyor belts. The main types of crushers are jaw crushers, cone crushers, hammer crushers, roller crushers, etc. The sand-making machine mainly includes impact crushers, fine crushers, hammer crushers, and so on. Different crushing and sand-making equipment are suitable for different materials and finished products.

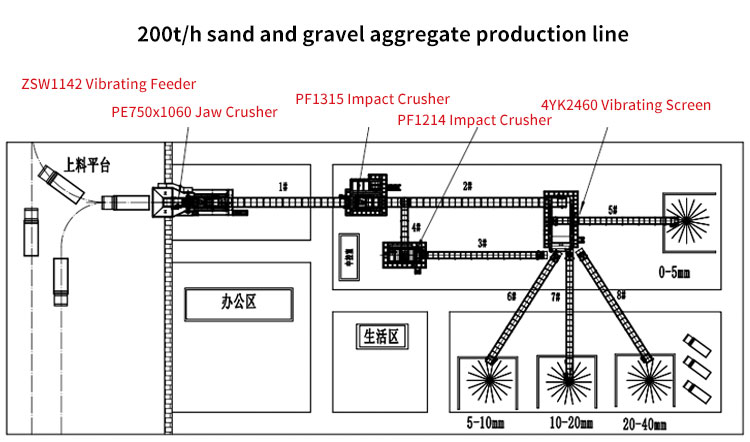

3. What is the specific configuration of the sand and gravel aggregate production line with an output of 200 t/h?

In the production of sand and gravel aggregates, our commonly used crushing equipment includes a jaw crusher, impact crusher, and vibrating screen. We will match and combine these crushing equipment according to the characteristics of the processed stone, the requirements of the quality of the finished product, and the setting of the production capacity.

Aggregates are generally divided into coarse aggregates and fine aggregates. Coarse aggregates are rock particles with a particle size greater than 4.75mm, mainly including pebbles and crushed stones. Fine aggregates are rocks with a particle size of less than 4.75m, such as river sand, mountain sand, sea sand, etc. According to the characteristics of these two materials, the configuration of our entire product line is mainly divided into four parts: feeding, crushing, sand making, and screening.

The specific configuration of the sand and gravel aggregate production line with an output of 200 tons per hour is a feeder, jaw crusher, impact crusher or cone crusher, sand making machine, and vibrating screen.

There are many factors that need to be considered in the configuration of the sand and gravel aggregate production line and the selection of equipment. How ensure the quality of the finished product is our top priority.