In the large-scale modern mining and coal washing industry, capacity and efficiency are the gold standard for measuring core competitiveness. When processing capacity remains below 100 tons, you may be able to cope; however, when market demand calls for much larger output, traditional production lines pieced together from multiple machines often prove inadequate—bottlenecks frequently appear, energy consumption is high, maintenance is complex, and ultimately, profit margins are eroded.

Today, we will delve into a game-changing solution: an integrated screening and crushing system with a processing capacity of up to 280 tons per hour. This is not merely an upgrade of a single machine, but a systemic restructuring of the entire production process.

I. Why "280 tons/hour"?

A processing capacity of 280 tons per hour (TPH) is a significant threshold. It signifies:

• Large-scale operation: Corresponding to the fuel pre-processing needs of large open-pit mines, regional coal storage and transportation centers, or large thermal power plants. It signifies that your business has entered the top tier of industrialized, large-scale production.

• Economic Break-Edge: At this capacity level, investing in a highly integrated system offers far greater overall benefits than maintaining a complex production line consisting of multiple small crushers and vibrating screens. It directly reduces the investment cost (CAPEX) and operating cost (OPEX) per unit output.

• Continuity Guarantee: It ensures a continuous and stable supply to downstream coal washing plants, chemical plants, or loading and transportation systems, avoiding downtime losses due to uneven upstream material supply.

II. Core Advantages of the 280 Tons/Hour Screening and Crushing System

This "jumbo" system's value extends far beyond its size. It integrates several key advantages, directly addressing the pain points of traditional production lines.

1. Intelligent Integration of "Screening Before Crushing" and "Crushing Before Screening"

High-end 280TPH equipment is often modularly designed, allowing for flexible process configuration based on raw material characteristics. For raw coal with a high pulverized coal content, a "screen-before-crush" approach can be adopted, allowing materials that meet the particle size requirements to be pre-screened, avoiding over-crushing and reducing equipment wear and energy consumption. For raw materials containing large pieces of gangue, a "crush-before-screen" approach can be adopted, ensuring that all materials are effectively crushed. This flexibility is the foundation for achieving efficient production.

2. High Integration, Optimized Footprint, More Conservative Investment:

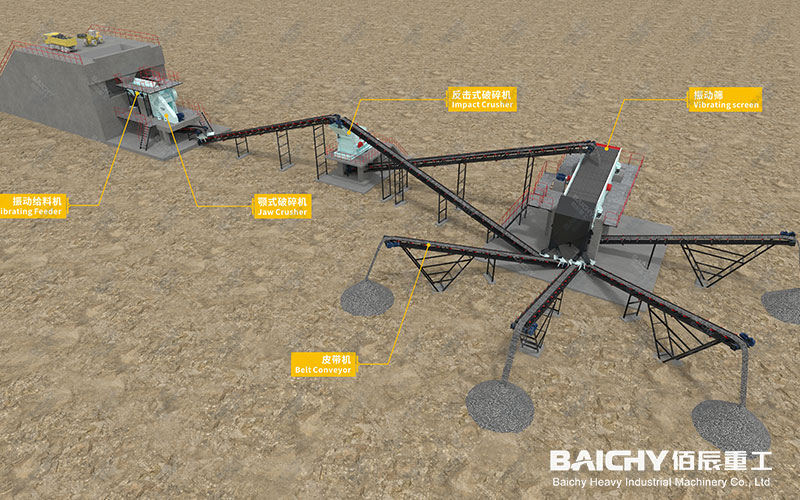

Traditional production lines require independent feeders, crushers, vibrating screens, multi-layer belt conveyors, and massive steel structure foundations. A mobile or semi-mobile station integrating screening and crushing functions significantly reduces the footprint, lowers civil engineering costs and equipment transfer requirements, and greatly shortens the installation and commissioning cycle, allowing for faster production and results.

3. Superior Particle Control Capabilities, Maximizing Product Value:

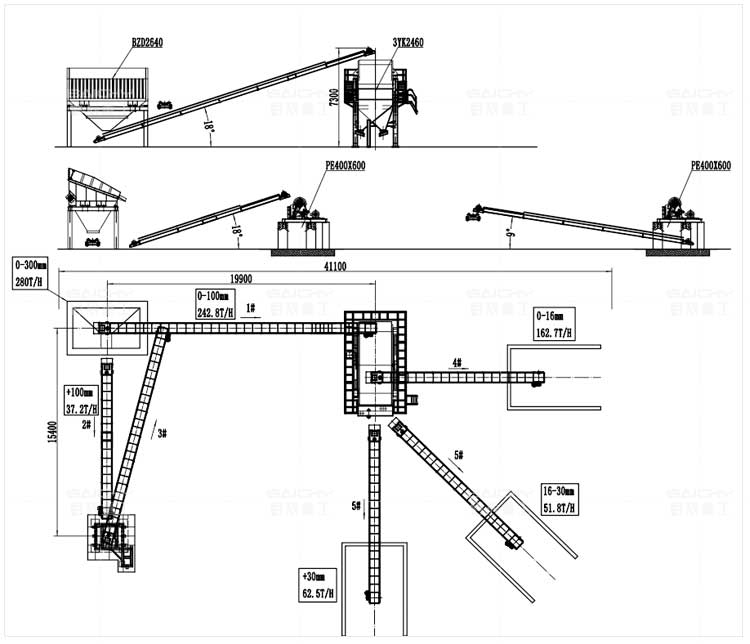

The value of coal is closely related to its particle size. The advanced 280TPH screening and crushing system employs a multi-layer vibrating screen and high-efficiency crushers (such as toothed roller crushers and double-stage crushers), precisely controlling the output within the target particle size range (e.g., 0-10mm, 10-30mm, 30-50mm), significantly improving the yield of high-value coal types and meeting the personalized needs of different customers.

4. Intelligent and Reliable Systems for Continuous Operation

For such high-load equipment, reliability is paramount. The system comes standard with an advanced PLC control system that monitors key parameters such as bearing temperature, vibration, and oil pressure in real time, enabling fault warnings and interlocking shutdowns. Key components such as bearings, screen plates, and crushing teeth are made of ultra-wear-resistant materials and are designed with convenient maintenance spaces, minimizing unplanned downtime.

III. Key Considerations for Choosing a 280 Tons/Hour Equipment

Faced with a perse range of products on the market, how do you make an informed choice? Here are some key decision points:

• Raw Material Characteristics Analysis: What are the hardness, moisture content, gangue content, and initial particle size of your coal? This is the primary basis for selecting the crushing method (impact, compression) and screen type.

• Target Output Requirements: How many types of final products do you need? What are the stringent requirements for particle shape? This determines whether to choose two-stage or single-stage crushing, and the number of screen layers.

• Mobility Needs: Is your mine a fixed mining site, or does it require frequent equipment relocation? This determines whether you should choose a stationary, semi-mobile, or fully mobile solution.

• Supplier's Overall Strength: Beyond the equipment itself, it's crucial to examine the supplier's case experience, after-sales service network, spare parts supply capabilities, and ability to provide customized design solutions. The value of a responsible partner becomes increasingly apparent throughout the project's lifecycle.

Investing in a 280-ton/hour screening and crushing plant is not simply a replacement of equipment, but a strategic capacity upgrade. It's about how to build your own cost advantage and quality barrier by improving technological equipment in an increasingly competitive market environment.

It solves not only the problem of "fragmentation," but also the problem of how to achieve value transformation more intelligently, economically, and reliably. When your production line can operate efficiently at a stable pace of 280 tons per hour, you will have the strong confidence to lead the market.