In fields such as ore processing, building materials production, and metallurgy and chemical engineering, material crushing and grinding is a core process. However, when dealing with raw materials with high moisture content, traditional grinding equipment is often inefficient and prone to clogging, seriously impacting production efficiency and product quality.

To address this industry pain point, the YGM95 Drying and Grinding Production Line was developed. With its unique integrated design, it is the ultimate solution for grinding high-moisture materials.

1. What is the YGM95 Drying and Grinding Production Line?

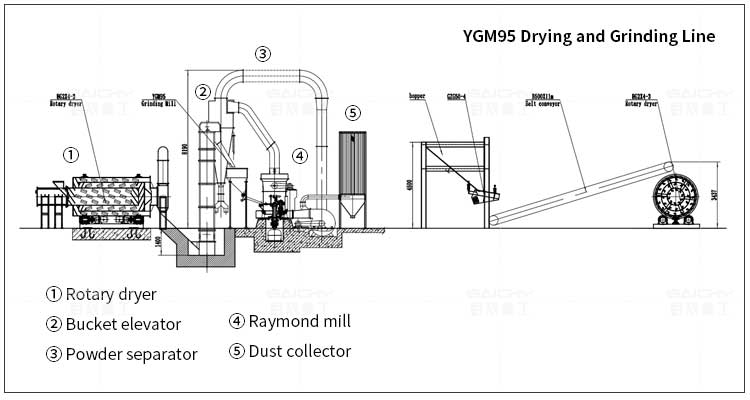

The YGM95 Drying and Grinding Production Line is more than a simple stack of equipment; it is an automated production system that integrates material drying, grinding, grading, and conveying.

Based on the classic YGM95 high-pressure suspension roller mill, it innovatively integrates a high-efficiency hot air furnace and drying system at the front end, effectively drying the material before it enters the grinding chamber, achieving continuous and efficient processing from "wet material" to "finished powder."

2. Core Advantages: Why Choose the YGM95 Drying and Grinding Production Line?

1. Integrated Design, Simplified Process: Combining the drying and grinding processes into one, the YGM95 reduces intermediate transportation and storage steps, saves plant space and equipment investment, and optimizes the production process.

2. Overcoming High-Moisture Challenges, Widely Applicable: Designed specifically for materials with moisture contents of 10%-15% or even higher (such as slag, coal, clay, and bentonite), it effectively solves the problem of traditional mills malfunctioning due to material adhesion and clogging.

3. High Efficiency and Energy Saving, Low Operating Costs: The system utilizes a scientific hot air circulation and thermal insulation design for high thermal energy utilization. Furthermore, the YGM95 main unit utilizes the proven roller and ring compaction principle, resulting in low power consumption and high output, effectively reducing unit production costs.

4. Stable Product Quality: The stable drying system ensures consistent dryness of the incoming material, resulting in a uniform fineness, concentrated particle size distribution, and excellent quality in the final powder.

5. High Level of Automation: The production line can utilize a PLC control system for centralized control, easy operation, and a dust-free working environment, meeting environmental requirements.

III. Main Technical Parameters and Applications

• Finished Product Fineness: Flexible adjustment within the 80-425 mesh range.

• Applicable Materials: Widely applicable to various non-flammable and non-explosive minerals with a Mohs hardness of up to 9.3, such as quartz, feldspar, calcite, talc, barite, fluorite, slag, slag, cement clinker, etc.

The YGM95 Dry Grinding Production Line represents a key development in modern industrial milling technology towards intelligent, intensive, and efficient production. It not only solves the challenges of grinding high-moisture materials, but also provides powerful equipment for businesses to enhance product competitiveness and achieve cost reduction and efficiency gains. If you are struggling with material moisture issues, the YGM95 Dry Grinding Production Line is undoubtedly a trustworthy choice.

Please contact us for a customized technical solution and quote!