In industries such as mining, construction, highways, and railways, a well-designed sand and gravel production line is the cornerstone of success. Medium-sized sand and gravel crushing production lines with an hourly output of 80-100 tons have become the first choice for many investors due to their high return on investment, stable capacity, and flexible configuration.

This article will systematically introduce each link of this complete production system.

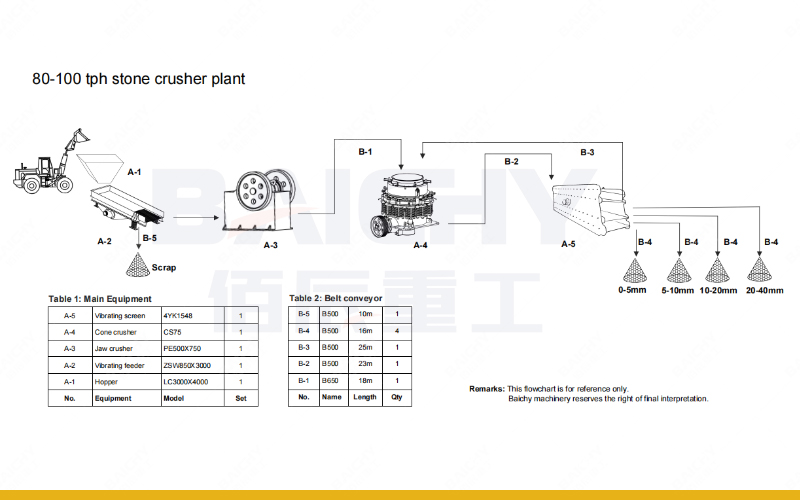

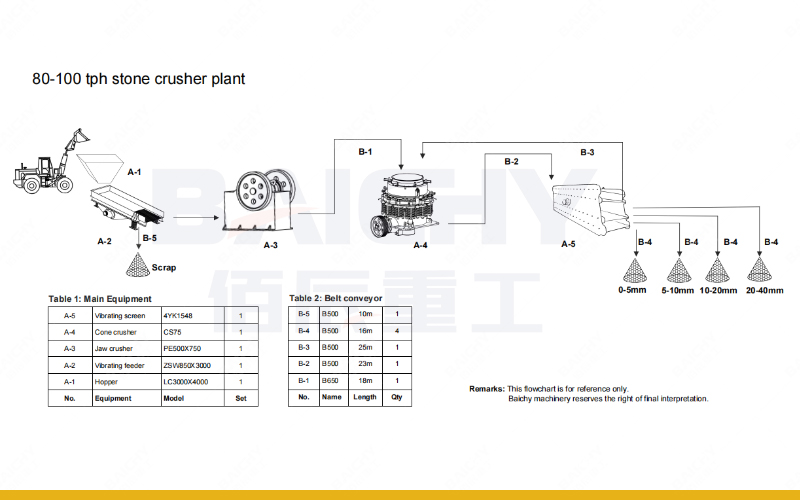

I. Core Components of the Production Line

An efficient 80-100 ton/hour sand and gravel production line is not a simple aggregation of inpidual pieces of equipment, but an organic whole.

1. Feeding System: A Uniform and Efficient Starting Point

◦ Core Equipment: Vibrating Feeder

◦ Function: Like the "throat" of the production line, it is responsible for uniformly, continuously, and stably feeding large pieces of stone from the raw material silo into the next stage crusher, which is crucial to ensuring the smooth and efficient operation of subsequent processes.

2. Multi-Stage Crushing System: The Core Link of Precision

◦ Primary Crushing (Coarse Crushing): Typically uses a jaw crusher (such as PE600×900). As a "strongman," it can initially crush large raw materials, reducing them to medium particle size, preparing them for subsequent processing.

◦ Intermediate Crushing (Medium-Fine Crushing): Depending on the hardness of the raw material (such as the hard granite commonly found in Sierra Leone), a cone crusher is recommended. Its layered crushing principle produces high-quality aggregates with better particle shape and lower needle-like and flaky content, and the equipment is wear-resistant and durable.

◦ Fine Crushing and Sand Making (Optional): To increase product added value, a sand making machine (vertical shaft impact crusher) can be configured to shape and make sand from some of the crushed stone, producing high-quality manufactured sand to meet the needs of high-standard concrete.

3. Screening and Conveying System: The Link Between Grading and Connection

◦ Screening Equipment: The vibrating screen is the "quality inspector," responsible for strictly grading the crushed mixture according to different specifications (e.g., 0-5mm, 5-10mm, 10-20mm) to ensure the accuracy of the finished product.

◦ Conveying Equipment: Belt conveyors act as the "arteries," seamlessly connecting inpidual machines to achieve automated and continuous material flow, significantly reducing labor costs.

4. Environmental Dust Removal System (Optional but Important): A Guarantee for Green Production

◦ Core Equipment: Baghouse dust collector or pulse jet dust collector.

◦ Function: Effectively collects dust generated during production, significantly reducing pollution, meeting increasingly stringent environmental requirements, and achieving green production.

II. Why Choose the 80-100 Tons/Hour Solution?

• High Efficiency and Continuity: Matched equipment capacities and a rational design ensure the entire system can operate continuously and stably for extended periods, maximizing production capacity.

• Flexible Adaptability: Equipment parameters and even partial configurations can be flexibly adjusted according to raw material characteristics (hardness, moisture content) and final product requirements (stone specifications, manufactured sand ratio), offering strong adaptability.

• Environmental Protection and Intelligence: Dust removal equipment effectively controls dust; simultaneously, modern production lines can integrate intelligent control systems to achieve remote monitoring, fault diagnosis, and automatic operation, significantly reducing labor costs and improving safety and production efficiency.

Stone Crushing Plant PDF, Download ↓↓↓

III. Value of the Sierra Leone Project

The successful application in Sierra Leone proves that this 80-100 tons/hour production line perfectly meets local market demands:

• Fast Return on Investment: The medium-sized scale avoids huge investments, and stable production capacity can quickly meet the needs of regional infrastructure projects, resulting in rapid capital recovery.

• Strong Product Competitiveness: Multi-stage crushing and screening ensures reasonable aggregate gradation and excellent particle shape in the finished product, controllable manufactured sand quality, and high market acceptance.

• Sustainable Operation: Environmentally friendly and intelligent design enables long-term stable operation, aligning with the investment philosophy of sustainable development.

The 80-100 tons/hour sand and gravel production line is a market-proven, mature, and reliable medium-sized production solution. It not only provides high-quality materials for infrastructure development in Sierra Leone but also offers an ideal blueprint for clients worldwide planning to invest in medium-sized sand and gravel plants.

If you are planning to build a sand and gravel production line with similar capacity, whether a stationary or mobile solution, we will provide you with a full range of services from site surveys and customized solution design to equipment supply and technical support. Contact us for customized solutions and detailed quotes!