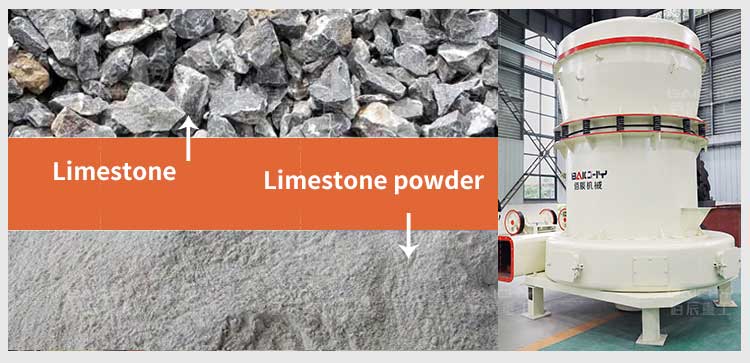

First of all, let us popularize the relevant knowledge about limestone.

Limestone is an important industrial raw material for metallurgy, building materials, chemical industry, light industry, agriculture and other sectors. With the development of the steel and cement industries, the demand for limestone will further increase. The output of cement is huge, that is, more than 100 billion tons of limestone need to be mined for cement products every year.

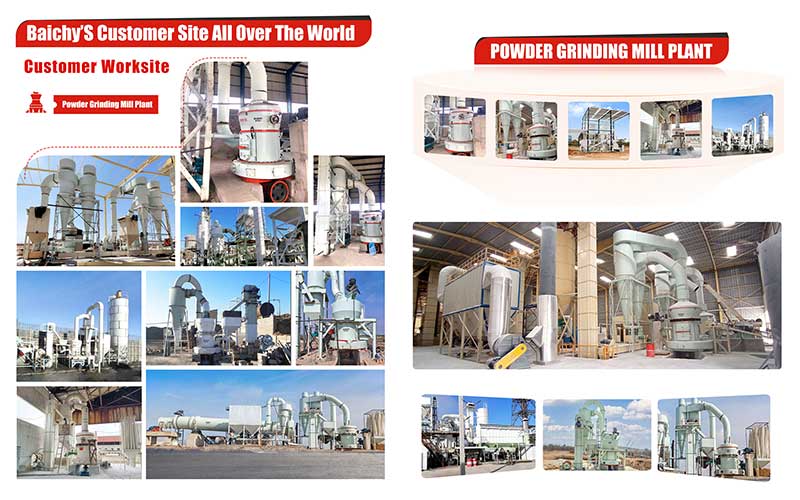

Limestone grinding mill

Limestone powder can be used in the production of quicklime, which is calcium oxide and slate lime, which is calcium hydroxide. There are many uses to limestone powder than simply producing quicklime and slaked lime.

It can be used to make other building materials, such as cement, mortar, and concrete. When limestone is crushed and heated with clay in a rotary kiln, cement is made. Cement can be mixed with sand and water to produce mortar which is used to glue bricks together.

Cement can also be mixed with sand gravel and water to produce concrete. Concrete when hardened is very strong. Pouring concrete on the steel bar structures creates reinforced concrete, which is even stronger.

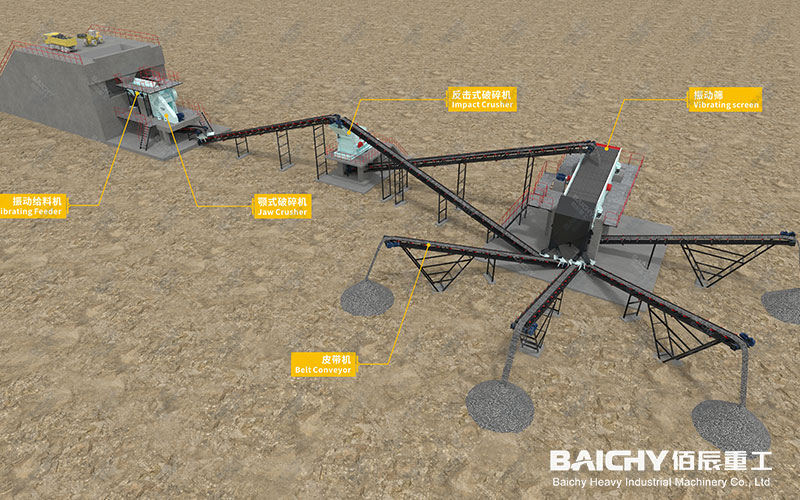

Crushing and grinding process of limestone

The first stage: coarse crushingLimestone, which is relatively brittle with a Mohs hardness of 3, can be broken initially by a jaw crusher. After the bulk limestone of 0-750mm is conveyed to the jaw crusher, limestone with a particle size of about 70mm will be generated, and the phenomenon of over-crushing will not occur. The coarsely crushed material will be screened by a vibrating screen and then conveyed to the medium and fine crushing equipment by a belt conveyor.

The second stage: medium and fine crushingIn the medium and fine crushing stage of limestone, various crushers such as cone crusher, hammer crusher, roller crusher and impact crusher can all be selected. However, due to the high investment of the cone crusher and the small capacity of the roller crusher, a hammer crusher or an impact crusher will be a more appropriate choice.

After the limestone is crushed by the hammer crusher or impact rock crusher, the particle size of the limestone produced will be less than 25mm, and the material larger than 25mm will be returned to the crusher by a vibrating screen to be crushed again;

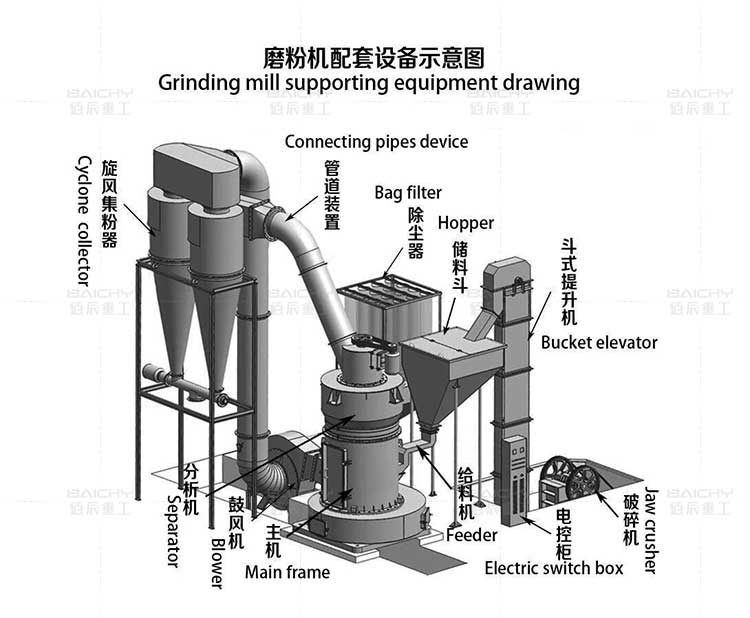

The third stage: grinding

The small pieces of limestone(≤30mm) will be sent to the silo by the bucket elevator, and then they can be evenly and quantitatively sent into the grinding mill by the vibrating feeder, which can produce ultrafine limestone powder.

Common Problems and Solutions

Question 1: Crusher output decreases?

Solution: Check if the discharge port is blocked, adjust the crushing ratio, or replace worn parts.

Question 2: Low grinding efficiency of ball mill?

Solution: Optimize the steel ball ratio, adjust the material filling rate, or upgrade the powder selection system.

Question 3: Severe dust pollution?

Solution: Install a pulse bag dust collector or use wet dust suppression technology.

Optimization of limestone crushing and grinding process can not only improve production efficiency, but also reduce energy consumption and operating costs. Choosing suitable crushing equipment (such as jaw crusher, cone crusher) and grinding equipment (such as ball mill, vertical mill), combined with scientific process management, can achieve high-quality and low-cost limestone powder production.

If you have specific needs (such as ultrafine powder processing, energy-saving transformation, etc.), please consult a professional team to get customized solutions!