How to Build a Stone Crushing Plant?

In today's booming infrastructure development, the efficient and economical production of high-quality sand and gravel aggregates is a core demand for many investors. However, building a stone crushing plant is far more than simply piling up equipment; it's a systematic engineering project requiring meticulous planning. Are you facing this dilemma: how to balance equipment investment, operating costs, and final output efficiency within a limited budget? How to choose the most suitable crushing solution for specific material types and product specifications? This article will provide you with a complete guide from scratch, systematically analyzing the construction process of a stone crushing plant to help you make informed decisions and avoid potential risks.

I. Basic Understanding of Stone Crushing Plants: More Than Just a Few Crusher Machines

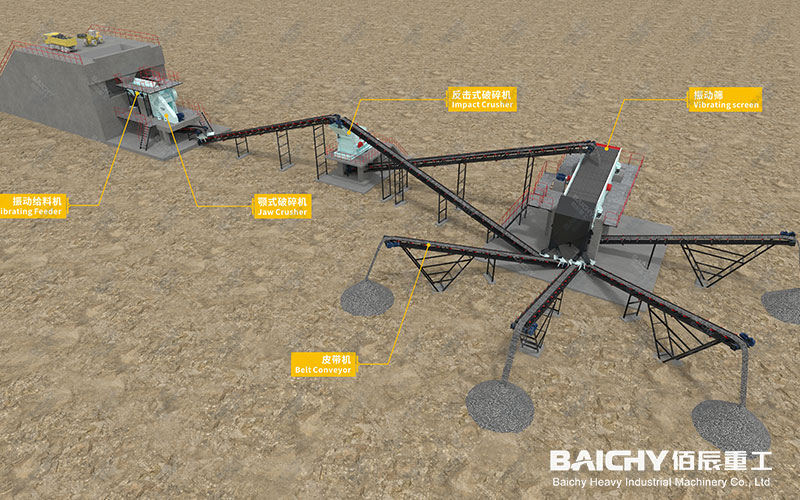

Before delving into the details, we first need to establish an overall concept. A modern stone crushing plant is essentially a highly collaborative production system, not just a combination of a few crushers.

• Core Definition: It is typically an organic integration of feeding equipment (such as vibrating feeders), multi-stage crushing equipment (such as jaw crushers and cone crushers), screening equipment (such as vibrating screens), and conveying equipment (such as belt conveyors).

• Basic Workflow: Raw materials enter from the hopper, undergo primary crushing (coarse crushing), and are then graded by a screening machine. Finished products meeting specifications are separated, while oversized particles enter the secondary crushing (medium and fine crushing) stage for closed-loop circulation until all materials meet requirements. Finally, they are transported to the finished product storage yard by a conveyor.

• Two Main Equipment Categories:

◦ Configuration Equipment: Responsible for material flow and placement, such as feeders, conveyors, and stacker cranes.

◦ Main Equipment: Undertakes core processing tasks, such as crushers at various levels and screening machines.

• Deployment Type Selection: Based on project cycle and flexibility requirements, it is mainly pided into mobile crushing stations (flexible relocation, suitable for short-term, decentralized projects) and fixed crushing lines (high capacity, strong stability, suitable for long-term, centralized production).

II. Detailed Explanation of Core Equipment: Building the Steel and Iron Skeleton of the Production Line

Choosing the right equipment is half the battle. Here is an in-depth analysis of key equipment:

1. Primary Crushing Equipment: The First Barrier in Production

This is the crucial stage for processing large raw materials (typically over 1 meter in diameter), determining the upper limit of the entire production line's processing capacity.

PE750x1060 Jaw Crusher

• Jaw Crusher: The first choice for hard rock crushing. Its working principle is similar to an animal's chewing action, crushing stone through the squeezing motion between fixed and movable jaw plates. Simple in structure and robust, it is the most widely used primary crushing equipment.

Coarse crushing equipment - gyratory crusher

• Gyratory Crusher: As a high-capacity alternative, it is suitable for processing highly abrasive materials with large production demands. It operates continuously, with a processing capacity far exceeding that of a jaw crusher of the same size, but its investment and maintenance costs are also higher.

• Supporting Equipment: Vibrating feeders and bar screens are indispensable. Bar screens remove dirt and fine debris before the material enters the crusher, preventing equipment blockage and ensuring stable and uniform feeding, protecting the crusher and improving efficiency.

2. Secondary Crushing Equipment: Refined Master Craftsmen

Responsible for medium and fine crushing and shaping of materials after coarse crushing to obtain aggregates with excellent particle shape and final specifications.

• Cone Crusher: Excels at crushing medium-hard rocks. Produces excellent particle shape with low needle-like and flaky content, particularly suitable for producing high-quality concrete aggregates. High wear resistance and relatively controllable operating costs.

• Impact Crusher: Utilizes a high-speed rotating rotor to impact the stone, achieving impact crushing. Advantages include good product particle shape, mostly cubic, and easy adjustment of discharge particle size. Ideal for producing road base aggregates of various grades.

• Vertical Shaft Impact Crusher: Typically used for tertiary crushing (sand making) and stone shaping. Through the stone-on-stone or stone-on-iron principle, it produces high-quality manufactured sand with reasonable gradation and rounded particle shape, a key piece of equipment for obtaining high value-added products.

3. Screening and Conveying System: The Circular Neural Network of Production

YK Series Vibrating Screen

• Vibrating Screen: The Command Center of the Production Line. Through multiple layers of screens with different apertures (metal woven mesh, polyurethane rubber screen, perforated steel plate, etc.), the crushed material is precisely graded into various specifications (e.g., 0-5mm, 5-10mm, 10-20mm, etc.).

Conveying equipment - belt conveyor

• Belt Conveyor: A Powerful Tool for Finished Product Stacking. The rear of the frame can rotate radially, achieving fan-shaped stacking, greatly reducing the transfer distance and cycle number of the loader, saving fuel and labor costs.

• Closed-Loop Circulation: A Manifestation of Intelligent Production. Oversized particles that do not meet the standards are automatically sent back to the crusher for further crushing on the vibrating screen, forming a closed-loop system that maximizes the utilization of raw materials and reduces waste.

III. Five-Step Construction Process: Clear Guidance, Step-by-Step Approach

1. Step One: Material Extraction and Loading. Use an excavator to extract raw materials; oversized stones can be pre-treated with a breaker hammer.

2. Step Two: Primary Crushing The pre-treated raw materials are evenly fed into a jaw crusher or gyratory crusher for coarse crushing via a feeder.

3. Step Three: Secondary Crushing and Screening. The coarsely crushed material is lifted by a conveyor to a vibrating screen for grading. The oversize material (large, non-conforming particles) enters a cone crusher or impact crusher for medium and fine crushing.

4. Step Four: Tertiary Crushing and Shaping (Optional). For producing manufactured sand or requiring extremely high particle shape, a VSI sand making machine can be configured for shaping and sand making.

5. Step Five: Finished Product Conveying and Stacking. The qualified finished products from each screening stage are transported to different finished product stockpiles via a radial stacker conveyor or a fixed belt conveyor.

IV. Pre-Project Decision Checklist: Five Dimensions to Help You Plan Accurately

Before starting the project, please clarify the following key questions:

Consideration Dimensions Key Questions That Must Be Answered

• Cost Budget: What is the upper limit for equipment investment? Have the life-cycle costs, such as replacement of wearing parts, energy consumption, and daily maintenance, been considered?

• Deployment Mode: How long is the project cycle? Is frequent relocation necessary? Is the flexibility of mobile crushing more important, or is the high capacity of stationary crushing more critical?

• Certification Standards: What are the target market requirements for aggregates (e.g., DOT certification)? Is HSI/VSI and precision screening required to ensure particle size distribution?

• Material Characteristics: What are the hardness (granite/limestone), silica content, and moisture content of the material to be crushed? What are the maximum feed size and final product specifications?

• Capacity Targets: What is the expected hourly output (tph)? How many different specifications of finished products need to be produced simultaneously?

V. Frequently Asked Questions (FAQ)

Q1: How to choose between a mobile crushing plant and a stationary crushing plant?

A: It depends on your operating scenario and capacity requirements:

| Dimensions | Mobile Crushing Plant | Stationary Crushing Plant |

| Applicable Scenarios | Multiple site relocations, on-site processing, short-term projects | Long-term quarries, high-capacity continuous production |

| Advantages | Reduced transportation costs, flexible deployment, rapid commissioning | High capacity, stable operation, low unit cost |

| Investment Costs | Higher initial investment | High infrastructure costs, but relatively low equipment unit price |

| Optimal Capacity | Typically 100-400 tph | Up to 500+ tph |

Recommendation: Choose mobile crushing plants for short project cycles and frequent site relocations; choose stationary crushing plants for long-term fixed operations and maximizing capacity.

Q2: Why does my crushing plant's capacity always fall short of design standards?

A: Common Bottlenecks and Solutions:

1. Unstable Feeding → Check for grid bar blockage and adjust vibrating feeder speed.

2. Improper Crusher Discharge Port Setting → Optimize the tight-side discharge port (CSS) according to the target particle size.

3. Low Screening Efficiency → Check screen wear and confirm screen type matches material.

4. Excessive Closed-Loop Circulation Load → Adjust screen size and reduce return material.

5. Insufficient Conveying Capacity → Upgrade conveyor bandwidth or speed to ensure upstream and downstream matching.

Key Principle: Balance the capacity of each station; the weakest link determines the overall line output.

Q3: How to plan the replacement cycle and cost of wear parts in a stone crushing plant?

A: Key Wear Parts and Reference Lifespan:

| Equipment | Wear Parts | Reference Lifespan | Cost Percentage |

| Jaw Crusher | Jaw Plate | 4-12 months | 30-40% of maintenance costs |

| Cone Crusher | Mantle, Crusher Wall | 3-6 months | High manganese steel is more wear-resistant |

| Impact Crusher | Hammer, Impact Liner | 200-400 hours | Fluctuates greatly depending on feed hardness |

| Vibrating Screen | Screen Mesh | 2-8 weeks | Rubber screen mesh has a longer lifespan than metal mesh |

Cost Planning Recommendations:

- Reserve an annual maintenance budget of 10-15% of the original equipment cost

- Establish a stockpile of critical spare parts (jaw plates, hammers, screen mesh) to reduce downtime.

- Choose original equipment manufacturer (OEM) or high-quality alternatives to reduce long-term overall costs.

VI. Conclusion and Action Recommendations

The core of building a successful stone crushing plant lies in accurate planning in the early stages. Correct equipment selection is the cornerstone of efficient production, while a scientifically sound layout ensures that the equipment's maximum potential is realized. We hope this guide can clear away any confusion and provide a clear path forward.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!