Tracked Mobile Crushing Plant vs. Stationary Crushing Plant

The global mobile crushing equipment market is growing at a rate exceeding 12% annually, while China has set an ambitious goal of achieving a 30% resource utilization rate for construction waste by 2025. Behind this data lies the severe challenges faced by traditional stationary crushing production lines: resource waste from construction followed by idleness, continuously eroding profits due to raw material transportation costs, and the frequent relocation demands under environmental protection restrictions.

Faced with these industry pain points, a core question confronts decision-makers: Under what circumstances must a tracked mobile crushing station be chosen? Under what circumstances is a stationary system more cost-effective?

This article will provide you with a clear decision-making matrix, combined with four real-world case studies, to help you quickly identify the optimal solution.

I. Core Comparison: 5 Dimensions to Analyze the Two Models

1.1 Investment Cost Structure Analysis

| Cost Items | Tracked Mobile Station | Fixed Crushing Plant | Key Differences |

| Initial Equipment Investment | High (1.5-8 million RMB per unit) | Medium (2-10 million RMB per production line) | Mobile stations have high integration, eliminating the need for civil engineering. |

| Civil Engineering | Almost zero | Accounts for 30%-50% of total investment | Fixed plants require foundations, factory buildings, and conveyor belt corridors. |

| Installation Cycle | 3-7 days (instant production upon arrival) | 2-6 months | Mobile stations have a significant time cost advantage |

| Relocation Costs | Low (self-propelled or flatbed truck) | Extremely high (equipment disassembly and transportation) | Fixed relocation ≈ reconstruction |

| Total Life Cycle Costs | Short-term projects are better | Long-term stable production capacity is better | 3 years is the critical equilibrium point. |

1.2 Practical Comparison of Relocation Flexibility

The tracked self-propelled capability is the core advantage of the mobile station: climbing angles up to 30°, relocation speeds of 0-2 km/h, and excellent maneuverability in complex terrain.

The modular quick-release design further improves efficiency: hydraulic outriggers automatically level, belt conveyors fold quickly, and cables are plug-and-play, significantly reducing preparation time.

In contrast, fixed relocation is extremely costly: requiring equipment hoisting, foundation dismantling, and pipeline cutting, with a single relocation costing up to 20% of the equipment value, almost equivalent to rebuilding.

1.3 Unveiling the Truth About Production Capacity and Efficiency

In terms of theoretical production capacity, the processing capacity of equipment of the same specifications is comparable (e.g., a jaw crusher with a capacity of 100-500 tons per hour).

However, actual production capacity varies significantly:

• Mobile stations: Limited by raw material distribution, requiring frequent relocation, with an actual utilization rate of 60-80%.

• Fixed stations: Continuous operation, with utilization rates exceeding 90%.

The comprehensive efficiency formula is: Effective capacity = Equipment capacity × Utilization rate × Raw material transportation cost coefficient.

1.4 Environmental Compliance Adaptability

Mobile stations have clear advantages: They can avoid monitoring of fixed pollution sources, operate in enclosed workshops, and quickly leave areas under strict environmental control.

Fixed stations also have their advantages: They facilitate centralized treatment of dust/wastewater, are easier to pass environmental impact assessments, and long-term environmental investment can be amortized.

1.5 Intelligentization vs. Manual Dependence

Modern mobile stations typically come standard with: wireless remote control, GPS positioning, fault self-diagnosis, one-button start/stop, and other intelligent functions.

Fixed stations require additional DCS systems, resulting in higher costs for intelligent transformation.

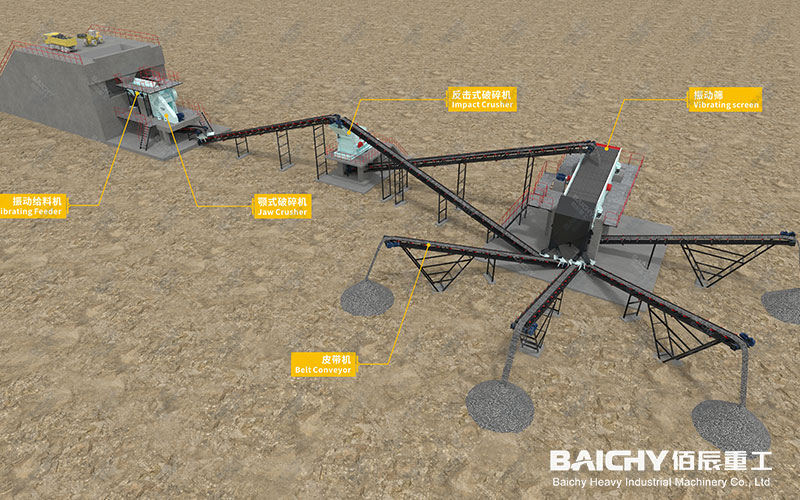

Production process of 300tph tracked mobile stone crushing equipment

II. Scenario-Based Selection: In-Depth Analysis of 4 Typical Projects

Scenario A: Urban Construction Waste Recycling Project (Mobile Station Highly Recommended)

Project Characteristics: Raw materials scattered throughout the city, complex composition (mixture of concrete/bricks/asphalt), environmentally sensitive, tight schedule

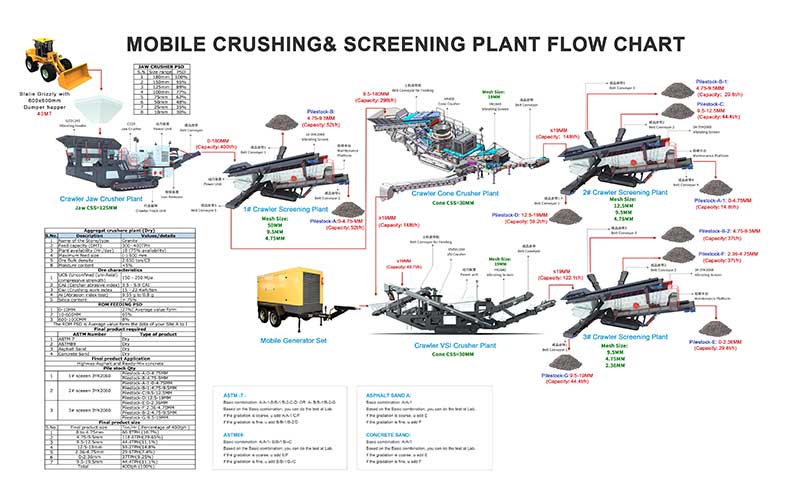

Configuration Scheme: Tracked Jaw Crusher + Tracked Impact Crusher + Tracked Screening Station (Three Units Working Together)

Core Advantages: Direct access to demolition site → crushing → screening → on-site backfilling or off-site transportation of recycled aggregate, saving on raw material transportation + stockpile rental

Economic Benefits: 60% reduction in transportation costs, 50% reduction in project cycle

Scenario B: Short-Term Mining/Tailgating Treatment (Mainly Mobile Stations)

Project Characteristics: Limited resource reserves (3-5 year mining period), large variations in mine depth, requires advancement along with the mining face

Configuration Scheme: Tracked Jaw Crusher + Tracked Cone Crusher (Hard Rock) ) or tracked impact crusher (soft rock)

Key decision points: If resources are <5 million tons, the mobile station has a better life-cycle cost; if >10 million tons, a fixed station + short-distance conveyor belt solution is more economical.

Scenario C: Highway/railway subgrade construction (mobile station is a necessity)

Project characteristics: Linear engineering 100-300 km, on-site utilization of tunnel muck, frequent changes in project sections

Configuration: Tracked jaw crusher + tracked screening station (producing graded crushed stone), or a single tracked impact crusher (producing manufactured sand)

Value points: Turning tunnel muck into valuable resources, reducing spoil heap land occupation, sand and gravel self-sufficiency rate >80%

Scenario D: Emergency rescue and post-disaster reconstruction (mobile station is the only solution)

Project characteristics: Tight schedule, undetermined site, unstable power supply

Configuration: Diesel-powered tracked jaw crusher (prioritizing large pieces of rubble) + Tracked Screening Station

Irreplaceability: Deployment and commissioning within 72 hours, impossible with fixed stations

Limestone Tracked Crushing Station Customer Site

Limestone Tracked Crushing Station Customer Site

III. Decision Matrix: 3 Steps to Lock in the Optimal Solution

Case Study 1: Urban Construction Waste Recycling Project (Mobile Station Wins)

Project Background: A new district in a second-tier city needs to process construction waste from 5 demolition sites.

Total processing capacity: approximately 1.2 million tons; construction period: 2 years.

Demolition sites are scattered, with the closest distance being 8 kilometers and the furthest 25 kilometers.

Strict environmental requirements necessitate operation in enclosed areas.

Selection Analysis:

• Project Cycle: 2 years < 3 years (critical point) → Mobile station +1 point

• Raw Material Distribution: 5 scattered points, maximum storage capacity at one point: 300,000 tons → Mobile station +1 point

• Relocation Needs: Relocation every 4 months on average → Mobile station +1 point

• Environmental Risk: Located in an urban built-up area, frequent environmental inspections → Mobile station +1 point

Decision Process:

• Fixed Station Solution: Requires construction of a fixed site; raw material transportation costs account for 45% of the total cost.

• Mobile Station Solution: Equipment can be directly deployed to the demolition site, reducing transportation costs by 18%.

• Final Selection: Combination of 2 tracked mobile stations, reducing total project costs by 35%.

Case Study 2: Large-Scale Granite Mine Project (Fixed Station Wins)

Project Background:

• Resource reserves of 20 million tons, mining period of 15 years

• Concentrated mining area, relatively fixed mining face

• Annual output of 1.5 million tons, products transported and sold externally

• Environmental impact assessment passed, mining area infrastructure is complete.

Selection Analysis:

• Project cycle: 15 years > 5-year critical point → Fixed station +1 point

• Raw material distribution: Single mining area, huge reserves → Fixed station +1 point

• Production capacity requirements: 400 tons per hour, requiring stable and continuous production → Fixed station +1 point

• Investment budget: Sufficient budget, pursuing long-term returns → Fixed station +1 point

Decision Process:

• Mobile station solution: High equipment investment, high long-term maintenance costs

• Fixed station solution: Although civil engineering investment is large, the cost per ton is lower during the 15-year operating period. Final Choice: Stationary crushing and screening production line with belt conveyor system

IV. Avoidance Guide: Common Selection Misconceptions

Misconception 1: Mobile stations have lower capacity than stationary stations.

Actual Situation: For equipment of the same specifications, mobile stations can achieve the same capacity through parallel operation of multiple units. 500-ton-per-hour mobile production lines are already mature.

Misconception 2: Mobile stations are only suitable for small projects.

Actual Situation: Modern mobile stations can meet the needs of medium to large-scale mines. The key is the project characteristics, not the scale.

Misconception 3: Mobile stations are more expensive and therefore not cost-effective.

Actual Situation: Ignoring hidden costs such as civil engineering, installation, and relocation, the total cost of a mobile station for a 3-year project is often lower.

Misconception 4: Stationary stations are more stable.

Actual Situation: The reliability of modern mobile station hydraulic systems has reached the level of stationary stations, with a failure rate difference of <5%.

V. Conclusion and Action Recommendations

In short: Choose tracked mobile stations for short-term, decentralized, and high-risk projects; choose stationary crushing plants for long-term, centralized, and large-scale projects.

Next Steps Recommended:

1. Download the Crushing Equipment Selection and Evaluation Form (Excel tool) and perform detailed calculations.

2. Schedule an on-site inspection with an engineer to obtain a customized solution for your specific project.

3. Request case reports of similar projects (construction waste/mining/roadbed construction) for reference based on actual operational data.

Through the above comprehensive analysis, we believe you now have a clear understanding of the selection process for tracked mobile crushing plants and stationary crushing plants. Correctly selecting the equipment type will directly impact your return on investment and project success rate. For specific project needs, please contact our technical team for personalized solutions.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!