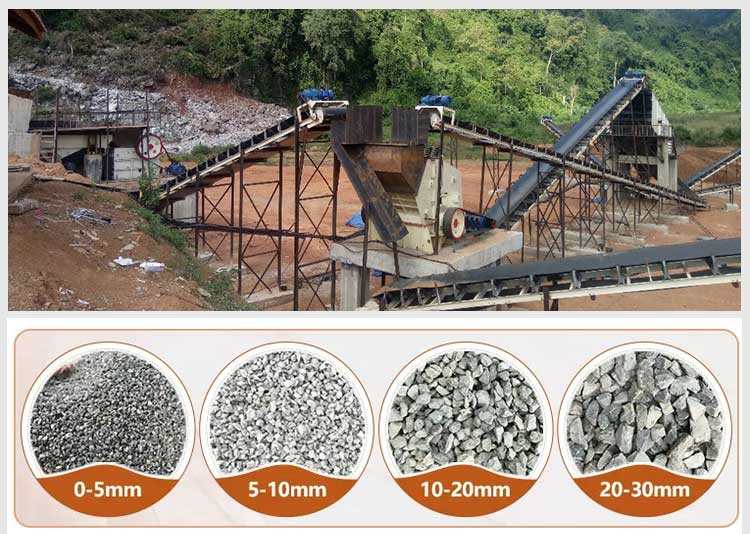

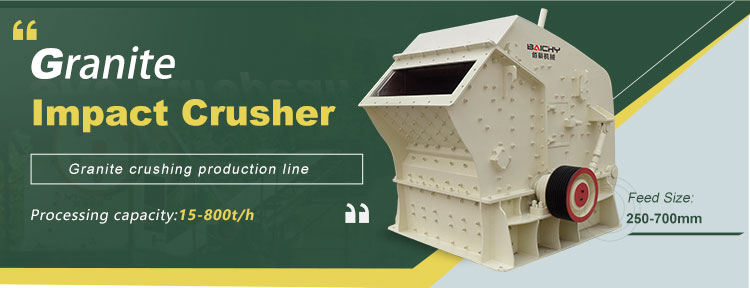

The final product particle size of the Baichy Impact crusher can reach 0-5mm, 5-10mm, 10-15mm; and the discharge port of the impact crusher can be adjusted to requirements; The quality of aggregate is high, so it will There is a tendency for more people to buy it.

The importance of high-quality aggregates?

Aggregate is one of the most important materials in the use of concrete. Aggregate can provide good stability for buildings, can play a role in reducing shrinkage, inhibiting crack growth, transferring force, reducing hydration heat, and providing abrasion resistance.

Concrete Aggregate Requirements

1. It has sufficient strength and sturdiness to ensure the role of skeleton force transmission.

2. Fewer impurities, do not affect the hardening of cement in the later stage;

3. The particles are uniform, the powder extraction rate is low, the particle shape is excellent, and the amount of cement slurry is reduced;

High-quality aggregates may have a very high market value, so people are more willing to invest in such equipment.

Three Performance Advantages of the Impact Crusher

First, the aggregate produced by the impact crusher has an excellent grain shape, mostly cubes, which is extremely beneficial to the increase of the compressive strength and elastic modulus of the concrete, so the aggregate produced by the impact rock crusher has sufficient strength.

Second, the final aggregate with needle content reduces the viscosity of the concrete mixture and enhances its fluidity and durability.

Third, it is easy to adjust the impact rock crusher to achieve good particle gradation. In addition, it can handle materials with different characteristics to meet different customer needs.

Impact crusher working principle

When the stone falls into the working area of the blow bar (hammer), it is crushed by the impact of the blow bar on the high-speed rotating rotor and is thrown to the apron for a second impact, and rebounds until the rotating blow bar (hammer) is hit again. This process is repeated until the material is crushed to the required size and discharged from the machine outlet.

Controlling the gap between the apron and the rotor can change the particle size and shape of the material. The smaller the gap, the finer the gradation.

Controlling the speed of the rotor can change the particle size of the material. The higher the speed, the finer the output.

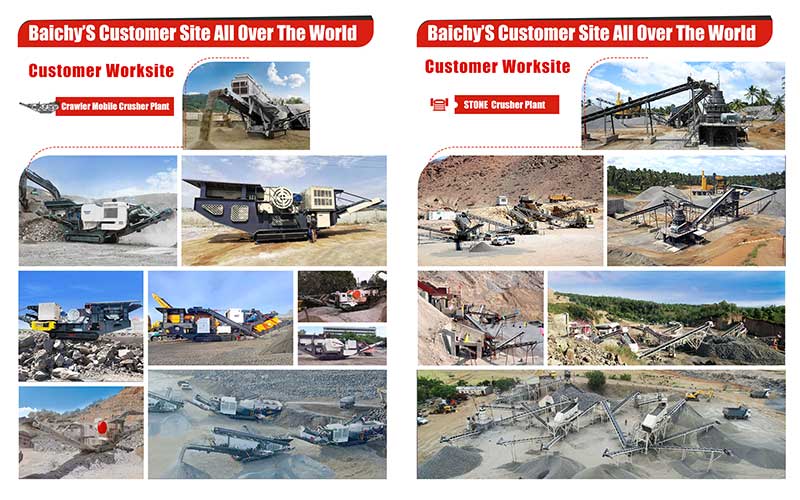

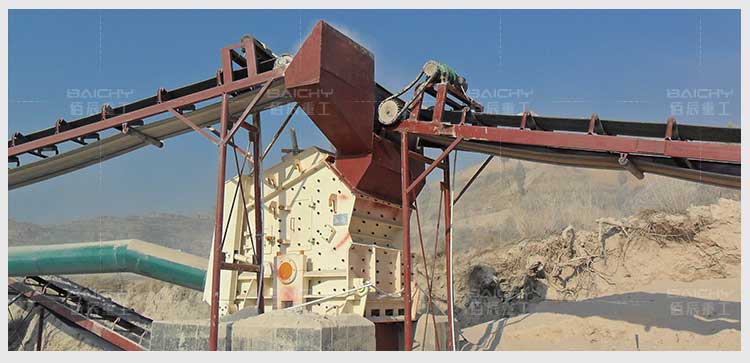

Baichy impact crusher is a highly efficient coarse, medium, and fine crusher for medium-hard and softer rocks. Whether in a quarry, mining, or construction waste recycling, the impact crusher can efficiently crush the stone, so that the particle shape, particle size distribution, and cleanliness are in line with the strict standards of concrete and asphalt aggregate. Impact crushing equipment not only achieves first-class product quality but also a remarkable throughput.