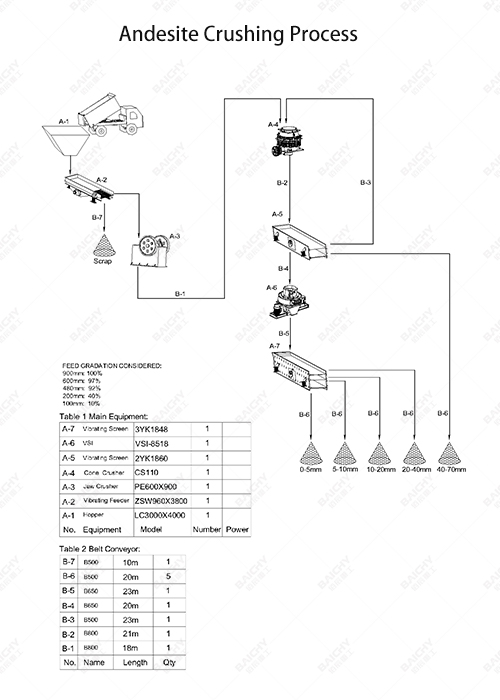

The andesite sand-making process provided by Baichy Machinery is generally divided into four stages: coarse crushing, medium and fine crushing, sand making, and screening.

Andesite sand making coarse crushing stage

The coarse crushing equipment generally uses a PE jaw crusher or CI large-mouth impact crusher, so here it is necessary to pay attention to the size of the raw material and the feed size of the coarse crushing equipment. The andesite stone material is evenly fed by the ZSW vibrating feeder through the silo and transported to the coarse crushing equipment for coarse crushing.

Andesite sand-making medium crushing stage

The coarsely crushed material is screened by the vibrating screen and then transported to the cone crusher by the belt conveyor for medium crushing. The crushed stone is transported to the vibrating screen by the belt conveyor, and stones of different specifications are screened out. The stone that meets the customer's particle size requirements is transported to the finished product pile by the belt conveyor; the stone that does not meet the standard is transported by the belt conveyor to the cone crusher for re-crushing, forming a closed loop.

Andesite sand-making stage

The crushed material is larger than the particle size of the two-layer screen, and the stone is transported to the sand-making machine by the belt conveyor for fine crushing and shaping.

Andesite screening stage

The finely crushed and reshaped materials are screened by the circular vibrating screen for coarse sand, medium sand, and fine sand.

Baichy Machinery reminds: For those who have strict requirements on sand powder, a sand washing machine can be installed after the fine sand. The wastewater discharged by the sand washing machine can be recovered through the fine sand recovery device, which can reduce environmental pollution on the one hand and increase sand production on the other.