Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

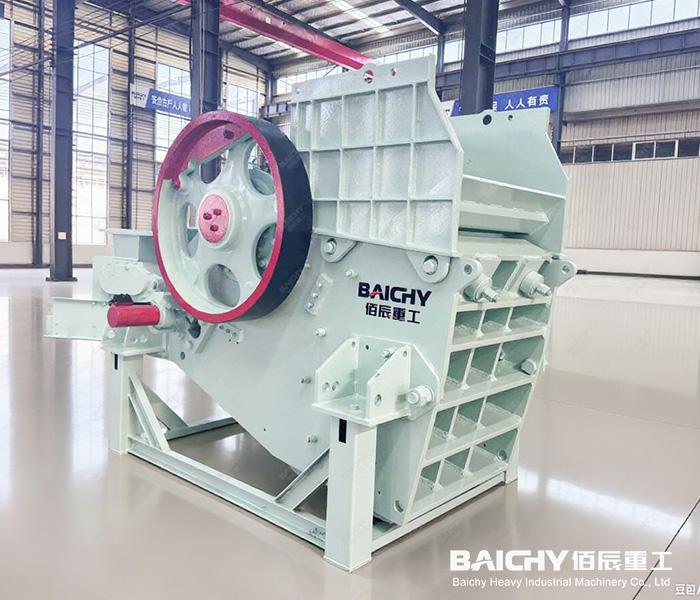

In the mining, construction, sand and gravel aggregate industries, jaw crushers are the core equipment in the coarse crushing process. CJ96 jaw crusher has become an ideal choice for small and medium-sized crushing sites with its high crushing efficiency, stable operation, and low maintenance cost.

• Processing capacity: up to 160 tons/hour (adjusted according to actual data), meeting the needs of small and medium-sized production.

• Feed port size: 0-480mm, which can easily cope with hard materials such as granite and basalt.

• Optimized cavity design: Enhance the crushing ratio, reduce over-crushing, and improve the quality of finished materials.

• High-strength frame: Made of high-quality steel, it has strong impact resistance and extends the life of the equipment.

• Replaceable wear-resistant parts: The jaw plate, liner and other wearing parts are made of high manganese steel, which is easy to replace and reduces downtime.

• Low energy consumption design: Optimize power matching, saving 20% energy compared with traditional models.

• Noise reduction and vibration reduction: Adopt a shock-absorbing base and closed structure to reduce noise pollution and meet environmental protection requirements.

| Model | CJ96 |

|---|---|

| Feeder Opening Size(mm) | 580×930 |

| Max. Feeding Size(mm) | 480 |

| Outlet adjusting Range(mm) | 60-170 |

| Centrifugal Shaft Speed(rmp) | 290 |

| Motor Power(kw) | 90 |

| Capacity(t/h) | 60-160 |

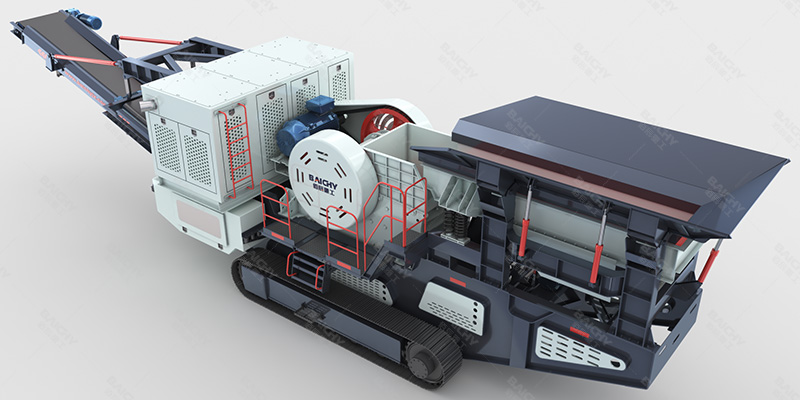

| Model | YMC96 |

|---|---|

| Feeder | GZD9638 |

| Jaw Crusher | CJ96 |

| Main Discharge Belt | B1000x12m |

| Side Discharge Belt | B500x3.8m |

| Capacity | 100-250t/h |

As a flexible and efficient crushing solution, the core host equipment of the YMC96 crawler mobile crushing station is the CJ96 jaw crusher. Why can this combination become the "golden partner" in the fields of mining, construction waste treatment, etc.?

1. Power synergy: The compact design of the CJ96 jaw crusher is highly compatible with the carrying capacity of the YMC96 crawler chassis, ensuring the stable operation of the whole machine.

2. Efficient coarse crushing: The 930×580mm feed port of the CJ96 can directly handle large materials (such as building concrete blocks, natural rocks) without the need for front-end pre-screening, reducing process links.

3. Fast transfer: The modular structure of the CJ96 jaw crusher is easy to integrate with the crawler chassis, and the equipment can be put into production within 30 minutes when transferring (saving 80% time compared to the fixed type).

1. Construction waste disposal: The hydraulic adjustment of the discharge port of CJ96 can quickly adapt to concrete blocks mixed with steel bars to avoid jamming.

2. Mountain mining operations: crawler climbing ability (up to 25°) + CJ96's low center of gravity design, stable crushing in rugged terrain.

3. Environmentally sensitive areas: Enclosed CJ96 crushing chamber + crawler station spray system, effectively controlling dust and noise (<75 dB).

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!