Applications and Supporting Solutions

The PE 600×900 is the go-to primary crusher for stationary stone production lines, designed first to reduce hard and abrasive materials.

• Applicable materials: River pebbles, granite, basalt, iron ore, quartz stone, diabase, construction waste, etc.

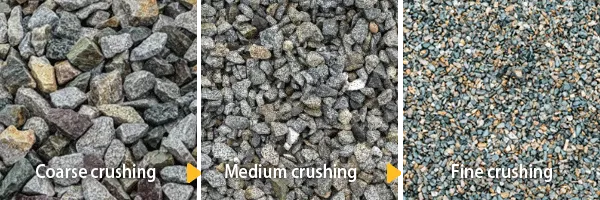

Typical production line configuration:

• Feeding equipment: ZSW-380×96 vibrating feeder

• Primary crushing equipment: PE-600×900 jaw crusher

• Secondary crushing equipment: PYB1750 cone crusher or PF-1214/1315 impact crusher

• Screening equipment: 3YK-1860 vibrating screen

This configuration creates a standardized sand and gravel aggregate production line with an hourly output of 100-150 tons.

The PE 600×900 jaw crusher, with its durable quality, stable and efficient output, and wide adaptability, has become the undisputed mainstay of medium-sized stone production lines. Choosing a high-quality 69 jaw crusher lays the most solid and reliable foundation for your entire crushing project.

If you are planning a stone production line and need more detailed information, a specific quote, or configuration options for the PE 600×900, please feel free to contact our technical engineers for one-on-one professional service.