Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

A slag vertical roller mill is a highly efficient grinding device that integrates crushing, grinding, drying, and classifying. Designed specifically for processing high-moisture, high-hardness slag, it utilizes the principle of bed grinding to achieve large-scale, low-energy grinding of slag. The fineness of the finished product is adjustable, making it the preferred equipment for modern slag micro-powder production lines.

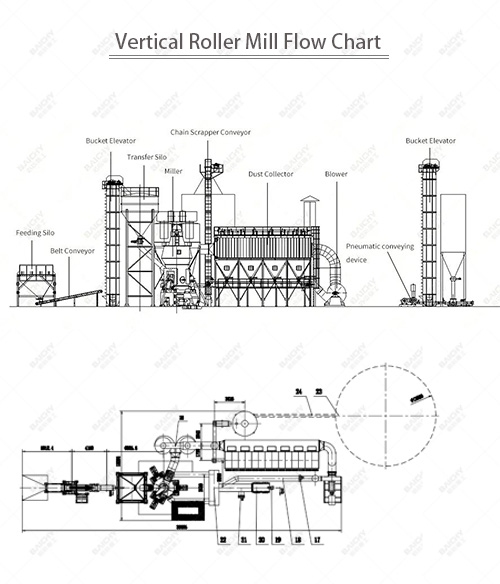

The material enters the center of the grinding disc through an air-locked feeder and is flung toward the edge of the disc by centrifugal force. At this point, hydraulically pressurized grinding rollers press against the material layer, crushing it. The crushed material is lifted by the high-speed airflow and dried and classified within the mill. Qualified fine powder flows out of the mill with the airflow and is collected as the finished product, while coarse powder falls back to the grinding disc for re-grinding. This process integrates multiple steps, including instant drying, simultaneous grinding, and efficient classifying, resulting in a compact process and extremely high efficiency.

• High Efficiency and Energy Saving, Lower Costs: Utilizing the material bed grinding principle, energy consumption is 30%-50% lower than traditional ball mills, significantly reducing production and operating costs.

• Integrated Drying and Grinding: Hot air can be introduced, eliminating the need for a separate dryer when processing high-moisture slag (e.g., 15% moisture content), streamlining the process and reducing investment.

• Stable and Controllable Product Quality: A built-in high-efficiency dynamic classifier allows for flexible adjustment of the finished product fineness (specific surface area) within a range of 400-550 m²/kg, resulting in excellent particle size distribution and high activity.

• Environmentally Friendly, Low Noise, and Reliable Operation: The equipment boasts excellent overall sealing and minimal dust collection points. It operates smoothly and produces significantly less noise than a ball mill, fully meeting environmental requirements.

The excellence of a vertical roller mill lies in its highly integrated design, integrating multiple processes into one, like a sophisticated "industrial lung," simultaneously completing grinding, drying, and sorting, achieving a leap in efficiency.

A vertical roller mill is like an efficient "giant juicer." The core process of grinding steel slag can be summarized in four steps:

1. Feeding: Pre-treated steel slag particles are continuously and evenly fed onto the rotating grinding disc inside the machine.

2. Compaction: Hydraulically applied rollers on the grinding disc crush the steel slag into a fine powder under tremendous pressure.

3. Drying and Air Separation: Simultaneously, hot air blown in from the bottom instantly dries the material and lifts the fine powder. Unqualified coarse powder falls back to the mill for re-grinding, while qualified fine powder rises with the air.

4. Collection: The airflow containing fine powder enters a bag filter, where the fine powder is collected as the finished steel slag fine powder. The purified air is then discharged.

Simply put: slag enters from the top, where it is crushed, dried, and sorted all at once within the machine, ultimately leaving a usable, high-quality fine powder directly at the bottom. This integrated design makes it far more efficient than traditional processes.

| Model | Grinding table dia.(mm) | Max feeding size(mm) | Discharge size(um) | Discharge size(mesh) | Air-in tempreture(℃) | Air-out tempreture(℃) | Input material moisture | Final moisture | Capacity(t/h) | Motor Power(kw) |

|---|---|---|---|---|---|---|---|---|---|---|

| SRM1300 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 10-35 | 185-250 |

| SRM1500 | 1500 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 13-48 | 250-355 |

| SRM1700 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 18-68 | 355-600 |

| SRM1900 | 1900 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 23-85 | 450-600 |

| SRM2200 | 2200 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 36-135 | 710-1000 |

The advantages are significant and primarily reflected in:

Energy saving: Power consumption is 30%-50% lower than a ball mill system.

High efficiency: With its built-in drying function, it can process materials with a moisture content of up to 15%-20%, eliminating the need for a separate dryer.

High product quality: The product offers a well-balanced particle size distribution, high activity, and easily adjustable fineness (specific surface area can reach 400-550 m²/kg).

Small footprint: With its three-dimensional structure, it occupies approximately 50%-70% of the floor space of a ball mill system.

Environmentally friendly and low noise: The entire system is well sealed, resulting in low operating noise.

Slag vertical mills are available in many models, covering a wide range of production capacities. Small vertical mills can produce tens to dozens of tons per hour, while large slag vertical mills can produce over 100 tons per hour, or even more, meeting the needs of production lines with an annual output of 300,000 tons to 1 million tons or more.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.