In the field of ore crushing and powder processing, vertical grinding mill production lines are becoming the preferred solution for many companies due to their superior performance and efficient production capacity. Whether grinding cement raw materials, coal, or deep processing non-metallic minerals, this production line demonstrates strong market competitiveness with its unique advantages.

This production line processes a wide range of materials and is a valuable asset in numerous industries:

• Building Materials Industry: Grinding cement clinker, slag, fly ash, and slag.

• Non-metallic Mineral Powders: Deep processing of calcite, limestone, barite, talc, marble, and potassium feldspar.

• Metallurgy and Chemical Industry: Grinding of metal ores such as manganese ore, iron ore, and phosphate rock.

• Power Industry: Preparation of desulfurization limestone powder for power plants.

Investing in a modern vertical grinding mill production line means you'll gain:

1. Significant Economic Benefits:

Low energy consumption and high output result in lower cost per ton of powder and a high return on investment.

2. Stable Product Quality:

The finished product features uniform particle size, flexible adjustment, and strong product competitiveness.

3. Environmental Compliance:

The entire system is well-sealed and equipped with a high-efficiency dust collector, ensuring environmentally friendly production.

4. Long-Term Development Potential:

A high degree of automation and low labor costs lay the foundation for large-scale, intelligent development.

Vertical grinding mill production lines represent the development direction of modern powder processing technology. They are not only a tool for improving production efficiency, but also a key piece of equipment for reducing costs, increasing efficiency, and achieving sustainable development. If you are planning to invest in or upgrade a powder processing project, choosing a vertical grinding mill production line with mature technology and optimized configuration is undoubtedly a key step towards success.

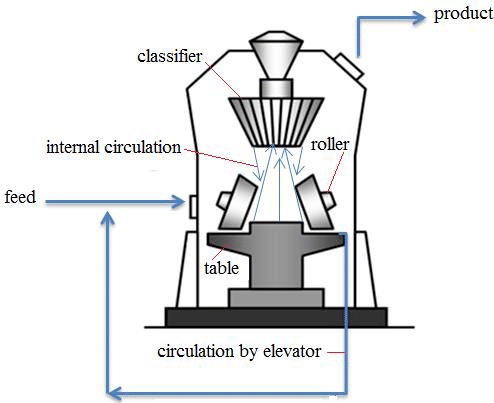

The vertical grinding mill is the heart of the entire production line. It utilizes an advanced roller and disc design to grind materials through a compaction process. Compared to traditional ball mills, it offers several significant advantages:

1. High Efficiency and Energy Saving: Energy consumption is 30%-50% lower than that of a ball mill, directly reducing production costs.

2. High Fineness and High Output: Powder fineness can be easily adjusted (typically from 80-600 mesh) to meet the needs of various industries, while achieving high output per unit.

3. Small Footprint: The compact vertical structure effectively conserves factory space.

4. High Drying Capacity: Hot air can be introduced for simultaneous grinding and drying, making it particularly suitable for materials with high moisture content.

5. Stable Operation and Low Noise: Low vibration ensures a quieter working environment and easy maintenance.

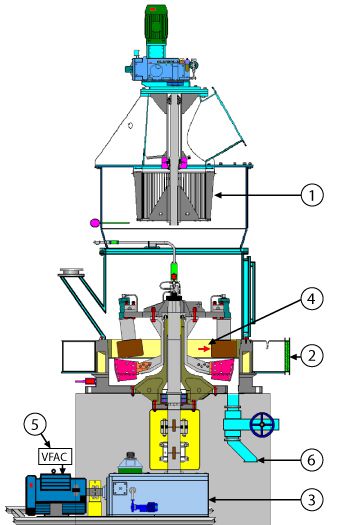

A complete vertical mill production line is far more than just a single machine. It's a coordinated system that typically includes the following key components:

1. Feeding System: A vibrating feeder evenly and continuously feeds raw materials (such as lump ore) to the next stage.

2. Crushing System (Optional): If the raw material particle size is large, it undergoes primary crushing using a jaw crusher or other equipment to meet the vertical mill's feeding requirements.

3. Elevating and Conveying System: Bucket elevators, belt conveyors, and other equipment are responsible for vertical and horizontal material transport.

4. Grinding Core: The vertical mill is the core component, grinding the material into the desired fine powder.

5. Classification System: An internal or external high-efficiency classifier promptly separates qualified fine powder and returns the coarse powder for re-grinding, ensuring a uniform particle size in the finished product.

6. Collection System: A pulse bag dust collector collects finished powder and ensures dust emissions meet environmental standards.

7. Automated Control System: Utilizing a PLC central control system, the entire production line is automated, with one-touch start and stop functions and real-time monitoring to ensure safe, stable, and efficient production.

These components are directly involved in the material crushing process and are the "heart" of the mill.

• Function: Mounted on the output shaft of the main reducer and driven by the motor. Its primary function is to support the material layer and, in conjunction with the grinding rollers, to form the grinding zone. Centrifugal force propels the material toward the edge of the grinding table.

• Features: Typically flat, bowl-shaped, or ridged, they are fitted with a replaceable wear-resistant liner.

• Function: These rollers, in pairs or groups, press against the material layer on the grinding table. They are not actively driven; instead, they are driven to rotate by the grinding table through friction with the material. Their primary function is to apply intense pressure to the material, crushing and grinding it.

• Features: Contains rolling bearings internally and a replaceable wear-resistant roller sleeve externally. Grinding Rollers are typically two to four in number.

• Function: Provides the positive pressure required for grinding on the grinding rollers. This system uses hydraulic cylinders to apply adjustable pressure to the grinding rollers (or the entire roller rocker arm). The level of pressure directly determines grinding efficiency and product fineness.

• Features: This is a core technology of modern vertical mills, allowing the equipment to flexibly adjust the grinding force based on feed rate and product fineness.

A feeder's job is more than simply delivering material to the mill. Its core mission is to continuously, evenly, and stably control the feed rate. This is directly related to:

1. Grinding mill operational stability: Fluctuating feed rates can cause drastic fluctuations in the thickness of the material layer within the mill, exacerbating mill vibration and even triggering shutdown protection, impacting continuous production.

2. Mill Operational Stability: Fluctuations in feed rate can cause drastic fluctuations in the material layer thickness within the mill, exacerbating mill vibrations and even triggering shutdown protection, impacting continuous production.

3. Grinding Efficiency and Energy Consumption: Uniform feeding is the foundation for a stable material layer. A stable material layer ensures efficient grinding by the rollers. Uneven feeding reduces grinding efficiency and significantly increases power consumption per unit of product.

4. Product Quality: Feed fluctuations affect the heat exchange efficiency between the hot air and the material inside the vertical mill, as well as the classifier's classification efficiency. This can ultimately lead to uneven fineness and unstable moisture content in the finished product.

5. Equipment Lifespan: Excessive vibration can cause impact damage to core components such as the grinding rollers, grinding discs, and reducers, shortening their service life.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.