Rock Crusher Machine

In traditional mining, stationary production lines require complex infrastructure and vast sites, exhibiting poor flexibility and extremely high relocation costs. The emergence of rock crushers, especially mobile ones, has completely changed this situation. Integrating feeding, crushing, screening, and conveying, it can be directly deployed to the work site for on-site material processing, representing the intelligent, efficient, and green development direction of mining equipment. This article will explore in depth how mobile rock crushers can become a powerful tool to enhance your mine's operational competitiveness.

What is a Mobile Rock Crusher?

A mobile rock crusher, as the name suggests, is a movable rock crushing equipment. It is not a single machine but a complete functional unit, typically integrating jaw crushers, impact crushers, cone crushers, vibrating screens, feeders, etc., onto one or more vehicle-mounted chassis. Traveling by tires or tracks, it possesses extremely high mobility, enabling it to quickly move between different work sites such as quarries, construction waste disposal sites, and mines, like a "walking crushing plant."

Core Advantages of Mobile Rock Crusher

Compared to traditional stationary production lines, mobile rock crushers offer unparalleled advantages.

1. Unmatched Flexibility

The equipment can be deployed directly to the production line, eliminating the expensive transportation costs of materials from the mining site to a fixed crushing station. It can be easily moved according to the needs of the mining schedule, achieving "wherever the raw material is, the equipment crushes it," greatly improving production efficiency.

2. Significantly Reduced Operating Costs

Mobile crushers reduce infrastructure costs such as site leveling and foundation pouring, and also significantly reduce fuel consumption and truck transportation costs. The equipment processes materials on-site, directly producing finished products of the required particle size, achieving effective cost control.

3. Rapid Deployment and High Adaptability

For projects with tight schedules or dispersed work sites, mobile rock crushers can quickly enter the site and begin production immediately after being connected to power (or using their own diesel engines). This rapid response capability makes them particularly suitable for contracted projects, urban construction waste recycling, and other similar scenarios.

4. Environmental Protection and Sustainability

By processing materials at the source, the number of trips by heavy trucks is reduced, thereby lowering noise and dust pollution. Simultaneously, it is a key piece of equipment for the resource utilization of construction waste, crushing waste concrete, asphalt, etc., into recycled aggregates, aligning with the concept of green development.

Mobile crushing station customer site

Success Story Sharing: Practical Application of Mobile Crusher

• Case Background: A large limestone mine in Southeast Asia, with a vast mining area and mining points constantly changing along the mountain range.

• Challenges: When using a fixed production line, trucks transporting ore needed to travel long distances along winding mountain roads, resulting in high costs, low efficiency, and significant safety hazards.

• Our Solution: We configured one tracked mobile jaw crusher and one tracked mobile cone crusher.

• Results: The two machines formed a mobile production line, advancing along the mining face. Production efficiency increased by approximately 40%, transportation costs decreased by over 60%, and operational safety was significantly improved, greatly shortening the return on investment period.

crawler jaw crusher

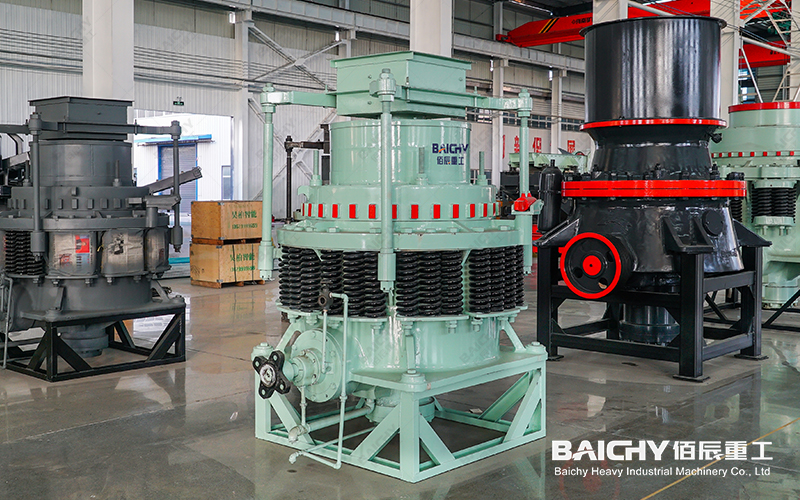

Recommended Equipment

We offer various configurations of mobile rock crushers to suit different material crushing and finished product requirements:

• Tracked Mobile Jaw Crusher: Suitable for primary crushing, processing large, hard rocks such as granite and basalt.

• Tracked Mobile Cone Crusher: Suitable for medium and fine crushing, producing finished products with excellent particle shape, commonly used in high-grade aggregate production.

• Tracked Mobile Impact Crusher: Suitable for medium crushing, adept at processing medium-hard materials, producing good particle shape, ideal for producing building stone.

• Tire-Mounted Mobile Crushing and Screening Station: Offers greater flexibility, suitable for frequent movement within the plant area or on flat surfaces.

Frequently Asked Questions (FAQ)

1: What are the main differences between mobile and stationary rock crushers?

The main difference lies in mobility and investment model. Stationary production lines require foundations and plant construction, representing a permanent investment, suitable for large mines with fixed ore sources and long mining lifespans. Mobile crushers require no infrastructure and can be quickly relocated, making them a flexible investment and more suitable for projects with short cycles, dispersed work sites, or frequent relocation needs.

2: Should you choose a wheeled or tracked chassis?

This depends on your operating terrain. Tracked chassis have low ground pressure and strong off-road capabilities, making them suitable for direct travel in rugged, muddy mine sites. Wheeled chassis require truck towing, offer faster movement, and are more suitable for transfers on flat plant areas or roads, but have certain requirements regarding on-site road conditions.

3: Can the capacity of a mobile crusher meet the needs of a large mine?

Absolutely. Modern large-scale mobile rock crushers can achieve hourly outputs of hundreds or even thousands of tons per unit. By combining multiple units to form a flexible mobile production line, their total capacity can rival that of small to medium-sized fixed production lines, while retaining the significant advantage of mobility.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!