300tph Tracked Mobile Granite Crushing Production Line

In the sand and gravel aggregate production sector, the choice of equipment configuration directly impacts the project's survival. A common misconception is that the more expensive the equipment, the better, but the reality is: incorrect equipment selection equals insufficient capacity, poor finished product quality, and soaring operating costs.

Industry data shows that 35% of crushing projects suffer from less than 60% capacity utilization due to improper configuration. This not only wastes equipment resources but also traps investors in a loss upon startup dilemma.

The correct configuration logic should be: material characteristics → crushing process → equipment combination → site layout → intelligent linkage. This article will guide you through a complete configuration system from single machine to dual machine to three-stage, a solution that can handle over 90% of crushing scenario requirements.

I. Single-Machine Operation Plan: Flexible and Mobile Special Forces

1.1 Tracked Jaw Crusher Station – King of Coarse Crushing

Tracked Jaw Crusher Station – King of Coarse Crushing

Equipment Characteristics Analysis

• Feed Size: ≤800mm (some large models can reach 1200mm)

• Processing Capacity: 100-500t/h

• Core Advantages: Strong impact resistance, excellent wear resistance, insensitive to material moisture content

Detailed Explanation of Independent Application Scenarios

• Application Scenarios Raw Material Characteristics Finished Product Use Key Configurations

• Surface Stripping in Mines Weathered rock, overburden Roadbed filling, site leveling Jaw crusher + pre-screening module

• Coarse Crushing in Building Demolition Reinforced concrete blocks Subsequent sorting or transfer coarse crushing Magnetic separator + spray dust suppression system

• Tunnel Mine Spoilage Treatment Large stones after blasting Graded crushed stone, temporary roads Heavy plate feeder + jaw crusher

Three Key Selection Points:

1. Discharge port adjustment range: Directly affects the ability to control the particle size of the finished product

2. Hydraulic overload protection: Ensures automatic protection when the equipment encounters uncrushable objects such as iron parts.

3. Tracked chassis ground pressure: Determines the equipment's passability on soft ground.

1.2 Tracked Cone Crusher Station – Expert in Medium and Fine Crushing of Hard Rock

Crawler Cone Crusher Plant

Technical Characteristics

• Applicable Hardness: Mohs hardness 5-9 (granite, basalt, quartzite)

• Crushing Principle: Layered crushing, cubic particle content up to 85% or more

• Processing Capacity: 80-350t/h

Independent Application Scenarios

• Medium and Fine Crushing in Hard Rock Mines: Performs medium and fine crushing on 150-200mm materials after coarse crushing.

• Processing of Highly Abrasive Materials: Special wear-resistant materials are used to handle raw materials with high silicon content.

• High-Standard Aggregate Production: Dedicated for railway ballast and highway surface aggregate.

Key Configuration Selection:

• Single Cylinder vs. Multi Cylinder: Single cylinder is easier to maintain, multi cylinder provides better particle shape.

• Cavity Type Selection: C-type (fine crushing), M-type (medium crushing), F-type (coarse crushing)

1.3 Tracked Impact Crusher Station – High-Efficiency Crusher for Soft Rock

Tracked Impact Crusher Station – High-Efficiency Crusher for Soft Rock

Performance Advantages

• Applicable Hardness: Mohs hardness ≤ 5 (limestone, dolomite, coal gangue)

• Crushing Principle: Impact crushing, excellent product particle shape

• Processing Capacity: 100-400t/h

• High Crushing Ratio: Up to 40:1, one-stage crushing can replace two traditional stages

Economic Benefit Comparison Table

| Application Scenarios | Finished Product Specifications | Economic Benefit Advantages |

| Cement Plant Limestone Crushing | 0-40mm | One stage replaces two stages, saving 35% on investment |

| Construction Waste Resource Utilization | 0-10mm/10-31.5mm | Rebar separation efficiency >95%, excellent powder control |

| Sand and Gravel Aggregate Production | Multiple specifications produced simultaneously | Good shaping effect, needle-like and flaky content <8% |

1.4 Tracked Screening Station – The Quality Inspector for Precise Grading

Three Major Functional Scenarios

1. Raw Material Pre-screening: Removes mud and fine powder, protecting downstream crushers.

2. Finished Product Grading: Simultaneous screening of 3-4 specifications, enhancing product value.

3. Material Recycling: Oversize material is automatically returned for re-crushing, improving finished product yield.

Technical Parameter Selection

• Number of Screen Layers: 2-4 layers, determined based on the quantity and specifications of the finished product.

• Screening Area: Calculated based on throughput and screening efficiency.

• Vibration Mode: Horizontal screen (fine grading), inclined screen (high-efficiency processing), banana screen (large throughput).

II. Dual-Unit Joint Operation: The Chemical Reaction of a Classic Combination

2.1 Golden Combination for Hard Rock Crushing: Jaw Crusher + Cone Crusher

Standardized Process Flow

Raw Material (≤800mm) → Tracked Jaw Crusher (coarse crushing to 150-200mm) → Tracked Cone Crusher (medium-fine crushing to 0-31.5mm) → Finished Aggregate

Applicable Material Range: High-hardness materials such as granite, basalt, diabase, and quartzite

Detailed Configuration Guide

| Key Aspects | Technical Points | Common Misconceptions Avoidance |

| Capacity Matching | Jaw Crusher Energy = Cone Crusher Energy × 1.2 (Buffer Coefficient) | Avoid excessive primary crushing causing secondary crushing jamming |

| Belt Connection | Adjustable height + large-angle belt design | Fixed belts cannot adapt to complex terrain |

| Recycled Material Handling | Material oversize from the cone crusher screen is returned or fed into the fine crushing chamber for re-crushing | Direct disposal results in resource waste |

Actual Case Parameters (200 tons/hour granite aggregate production line)

• Tracked Jaw Crusher Station: C110 type, discharge port set at 150mm

• Tracked Cone Crusher Station: HP300 multi-cylinder hydraulic, F-type fine crushing chamber

• Finished Product Specifications: 0-5mm (manufactured sand), 5-10mm, 10-20mm, 20-31.5mm

2.2 High-Efficiency Combination for Soft Rock: Jaw Crusher + Impact Crusher

Optimized Process Flow

Raw Material → Tracked Jaw Crusher (Coarse Crushing) → Tracked Impact Crusher (Medium and Fine Crushing + Shaping) → Multi-Specification Finished Products

Techno-Economic Comparison Analysis

| Comparison Items | Jaw Crusher + Impact Crusher Combination | Jaw Crusher + Cone Crusher Combination |

| Equipment Investment | 20-30% Lower | Higher |

| Power Consumption per Ton | 15-20% Lower | Higher |

| Lifespan of Wear Parts | Shorter (Impact Plate, Hammer) | Longer (Gnatant Wall, Crushing Wall) |

| Finished Product Particle Shape | Excellent (Cubic Content > 90%) | Good (Cubic Content > 85%) |

| Applicable Hardness | ≤5 Grade Medium Hard Materials | 5-9 Grade Hard Rock Materials |

Upgrade Recommendation: Add a tracked screening station after the impact crusher to form a closed-loop circulation system, increasing the finished product yield by more than 15%.

2.3 Specialized Combination for Construction Waste Resource Utilization

Special Configuration Requirements

• Iron Removal System: Self-unloading electromagnetic iron separator + manual sorting platform

• Light Material Separation: Air classifier effectively removes impurities such as plastics and wood chips

• Pre-screening Module: Removes 0-10mm powder material first, reducing the load on the crusher

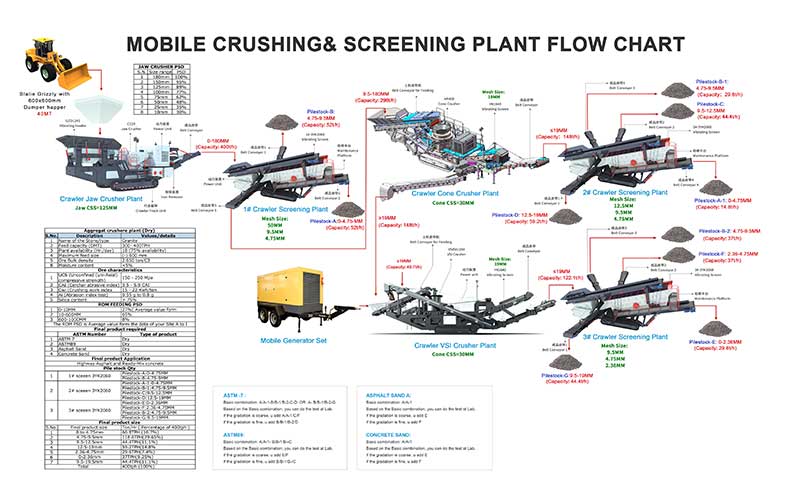

III. Complete Three-Stage Crushing Production Line: High-Quality Aggregate Manufacturing Plant

3.1 Standard Three-Stage Process Flow

3.2 Four-Unit Intelligent Configuration Scheme

Unit Location Equipment Function Model Example Key Parameter Settings

Unit 1 Tracked Jaw Crusher C110 Feed ≤800mm, Discharge 150mm

Unit 2 Tracked Cone Crusher HP300 Feed ≤200mm, Discharge 45mm

Unit 3 Tracked Sand Making Station VSI6X1263 Feed ≤50mm, Discharge 0-5mm

Unit 4 Tracked Screening Station 3YK3070 4-layer screen, 4 types of finished products

Intelligent linkage control system

• Intelligent material level sensing: Real-time monitoring of material level in the silo, automatic adjustment of feeding speed

• Belt interlock control: Automatic upstream shutdown protection in case of downstream equipment failure

• Automatic capacity balancing: Intelligent adjustment of crusher output based on screening load

4.3 Material hardness and equipment selection matrix

| Material type | Mohs hardness | Typical representative | Recommended configuration scheme | Core equipment selection |

| Soft rock | Grade 1-3 | Coal, gypsum, shale | One or two stages of crushing | Mainly impact crusher |

| Medium-hard rock | Grade 3-5 | Limestone, dolomite | Jaw crusher + impact crusher | Medium and fine crushing with impact crusher |

| Hard rock | Grade 5-7 | Granite, syenite | Jaw crusher + cone crusher | Single-cylinder/multi-cylinder cone crusher |

| High-hardness rock | Grade 7-9 | Basalt, diabase | Jaw crusher + multi-cylinder cone crusher + sand making machine | Multi-cylinder cone crusher + vertical shaft impact crusher |

| High abrasive material | - | High silica content river pebbles | Jaw crusher + wear-resistant cone crusher | Special wear-resistant material |

4.4 Finished product specifications and process adjustment strategies

Conventional aggregate specification system

• 0-5mm: Manufactured sand (fineness modulus adjustable from 2.3 to 3.0)

• 5-10mm: Flakes (fine aggregate for concrete)

• 10-20mm: Small stones (main coarse aggregate for concrete)

• 20-31.5mm: Large stones (material for foundation padding)

Dynamic process adjustment plan

| Target finished product requirements | Process adjustment measures | Equipment parameter optimization |

| Increase manufactured sand ratio | Increase sand making machine speed, reduce discharge port | Increase vertical shaft impact crusher speed by 10-15% |

| Reduce needle-like and flaky content | Select cone crusher with fine cavity type, reduce feed rate | Select F-cavity type, feed ≤80% load |

| Control powder content | Increase screening area, adjust screen angle | Screen inclination angle 15-20°, add screen cleaning device |

| Achieve continuous gradation | Multiple units in parallel, precise mixing of multiple specifications | 4 kinds of finished products blended according to gradation requirements |

V. Customized Configuration Solutions for Special Scenarios

5.1 Special Solution for High Moisture Material Handling

Core Problem: Screening efficiency drops sharply when material moisture content >10%, and the crushing chamber is prone to adhesion.

System Solution:

1. Pre-treatment stage: Install a heavy-duty vibrating feeder before the jaw crusher to pre-screen out soil impurities.

2. Crushing stage: Equip the impact crusher with a hot air drying device to reduce material viscosity.

3. Screening stage: Use anti-clogging polyurethane screens to improve screening efficiency.

5.2 Special Configuration for Ultra-hard Materials (Basalt/Quartzite)

Technical Challenges: Equipment wears out extremely quickly, resulting in significant capacity reduction.

Wear-resistant Upgrade Solution:

• Jaw Crusher Configuration: Deep cavity design + thickened high-manganese steel jaw plates

• Cone Crusher Upgrade: Multi-cylinder Hydraulic System + Optimized Layered Crushing

• Sand Making Machine Optimization: Prioritize stone-on-stone mode to reduce wear on wear-resistant parts

• Spare Parts Strategy: Stock up on vulnerable parts at twice the normal usage

5.3 Urban Environmentally Friendly Construction Waste Processing Line

Comprehensive Environmental Protection Measures:

• Noise Control: Fully enclosed equipment design + sound insulation cotton + nighttime operation time restrictions

• Dust Removal System: Inlet spray + belt sealing cover + pulse dust collector at screening station

• Water Circulation System: Car wash platform + three-stage sedimentation tank + filter press, achieving zero emissions

VI. Configuration Scheme Decision Flowchart

VII. Configuration Misconceptions and Avoidance Guidelines

| Common Misconceptions | Examples of Incorrect Practices | Correct Solutions | Severity of Consequences |

| Over-equipped crusher | 500t/h jaw crusher paired with 200t/h cone crusher | Strictly match capacity according to 1:1.2. | Cone crusher frequently jams, accelerating wear. |

| Misuse of impact crusher for hard rock | Use impact crusher for medium crushing of granite | Hard rock must use cone crusher | Replace hammer plates every 2 days, leading to uncontrolled costs. |

| Ignoring recycle material handling | Discarding screened material directly | Set up a recycle conveyor for re-crushing | Finished product yield reduced by 15-20%. |

| Uneven feeding | Loader directly dumps material into the crusher | Configure a vibrating feeder for uniform feeding | Crusher wears unevenly, causing large capacity fluctuations. |

| Excessive belt angle | Belt inclination angle > 20° | Control within a reasonable range of 15° | Severe material slippage, rapid belt wear. |

VIII. Conclusions and Action List

Core Conclusions Summary

1. Single-machine solution applicability: Suitable for projects with a capacity of <100t/h, single raw material, and short-term operation; highly flexible.

2. Dual-machine combination cost-effectiveness: Covers 80% of conventional needs, representing the optimal balance between investment and efficiency.

3. Necessity of tertiary production lines: An inevitable choice for high-quality aggregates, manufactured sand, and large-scale projects.

4. Primary decision-making basis: Material hardness is the primary factor in equipment selection, followed by capacity and finished product requirements.

Action recommendations:

1. Download materials: Obtain the Crawler Mobile Crushing Plant Configuration and Selection Manual (including detailed parameter tables).

2. Material testing: Submit material samples to obtain a customized configuration plan.

3. Site visit: Schedule a visit to a nearby project site to verify the configuration effect.

4. Scheme optimization: Invite a technical engineer to conduct an on-site survey and optimize the site layout.

Important Note: The configuration schemes provided in this article are based on industry standards. Specific projects require adjustments based on actual conditions. It is recommended to consult with professional technicians before selecting equipment for detailed material testing and scheme demonstration.

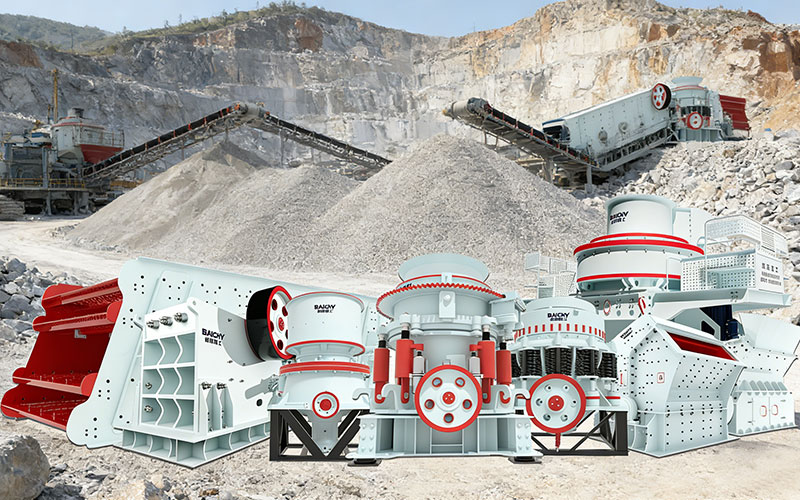

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!