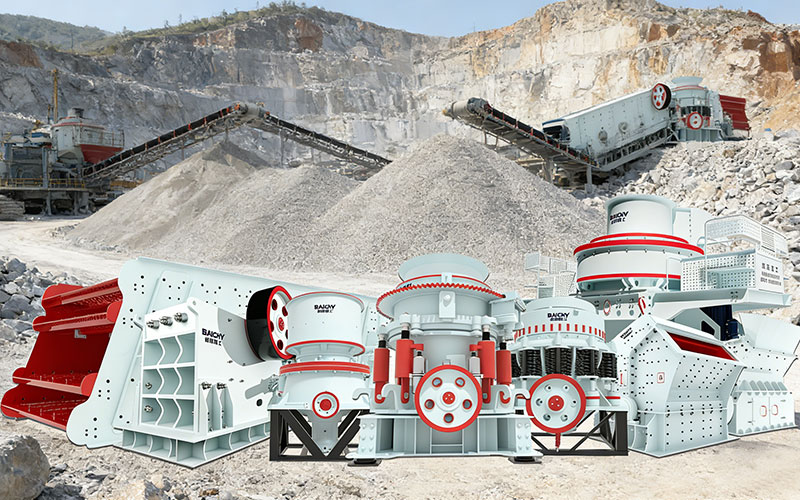

mining stone crusher

In mining, construction, and resource recycling, crushers are core equipment, and their selection directly impacts production efficiency and operating costs. This article will provide a detailed analysis of 8 mainstream crushing machine types and offer practical selection advice.

I. Overview of Crushing Machines: Basic Understanding

A crusher is a specialized piece of equipment that uses mechanical energy to crush stone, breaking large stones into aggregates of specific particle sizes. Modern crushers are not only used in traditional mining but also play a crucial role in the resource utilization of construction waste and road construction. With the deepening of the green mining concept, the value of crushers in resource recycling is becoming increasingly prominent.

II. 7 Key Factors for Selecting a Crushing Machine

1. Material Characteristics Analysis

The hardness and structural characteristics of different materials directly affect equipment selection. For example, high-hardness materials such as granite are suitable for jaw crushers, while medium-hardness materials such as limestone are suitable for impact crushers.

2. Production Scale Requirements

The varying hourly output requirements, ranging from tens to thousands of tons, directly dictate the model and specifications of the equipment.

3. Discharge Particle Size Standards

Different applications have specific requirements for the particle size of the finished product, which relates to whether a multi-stage crushing process is needed.

4. Site Conditions

Fixed production lines require ample space, while mobile crushing plants are suitable for situations with limited space.

5. Investment Budget Range

Equipment purchase costs and subsequent operating costs need to be comprehensively considered.

6. Environmental Requirements

Environmental indicators include noise control and dust control.

7. Energy Consumption Standards

Significant differences in energy consumption among different equipment directly impact long-term operating costs.

III. In-depth Analysis and Technical Comparison of 8 Types of Crusher

1. Jaw Crusher: The Main Force in Coarse Crushing

PE Jaw Crusher

Jaw crushers achieve crushing through the squeezing action between the moving and fixed jaws. Their unique V-shaped crushing chamber design ensures effective crushing of large materials. The latest models utilize hydraulically adjustable discharge ports, achieving intelligent control. The equipment boasts a crushing ratio of 6-8, a maximum feed size of 1500mm, and an adjustable discharge size range of 50-300mm.

Core Advantages:

• Deep crushing chamber for high processing capacity

• Heavy-duty eccentric shaft design for strong load-bearing capacity

• Optimized flywheel configuration for low energy consumption fluctuations

Applicable Scenarios: Primary crushing of ultra-high hardness materials such as granite and basalt, with an hourly output of up to 1500 tons.

2. Cone Crusher: The Precision Craftsman of Medium and Fine Crushing

Hydraulic Cone Crusher

Utilizing the principle of layered crushing, multi-layered crushing of materials is achieved through the relative movement between the moving and fixed cones. The hydraulic system provides overload protection, automatically discharging uncrushable foreign objects. The latest model is equipped with the ASRi intelligent control system, optimizing crushing parameters in real time.

Technical Features:

• Crushing ratio up to 10-15

• Uniform product particle size, high cubic content

• Hydraulic clearing system improves maintenance efficiency

Applicable Scenarios: Secondary crushing of high-hardness materials, especially suitable for the production of commercial concrete aggregates requiring strict particle shape.

3. Impact Crusher: The Artist of Particle Shape Optimization

PF Impact Crusher

Utilizing a high-speed rotating rotor to drive hammers to impact materials, the discharge particle size is precisely controlled by adjusting the gap between the impact plate and the rotor. The unique vortex crushing chamber design allows materials to receive multiple impacts and collisions within the chamber.

Innovative Design:

• Multi-chamber configuration adapts to different materials

• Hydraulic opening device facilitates maintenance

• Modular hammer design allows for reversible use

Applicable Scenarios: Crushing of limestone and recycled concrete with medium to low hardness, with an hourly output of up to 800 tons.

4. Mobile Crusher: A Versatile Operator

Mobile Jaw Crusher

Wheel-mounted models adopt a semi-trailer design with a small turning radius; tracked models are fully hydraulically driven with strong climbing ability. Equipped with an intelligent control system, enabling one-button start/stop and remote monitoring. The diesel-electric dual-power configuration ensures stable operation under various working conditions.

Configuration Highlights:

• Integrated unit, reducing on-site installation

• Multiple main units can be quickly replaced

• Environmentally friendly design, noise level below 75 decibels

Applicable Scenarios: Mobile operations such as construction waste recycling, mine surface stripping, and urban demolition projects.

5. Vertical Shaft Impact Crusher: The Professional Engineer of Manufactured Sand

VSI Sand Making Machine

Utilizing the stone-on-stone or stone-on-iron working principle, crushing materials through self-impact within the crushing chamber. The unique impeller design allows for precise acceleration control of the material, ensuring stable fineness modulus of the finished sand.

Technical Parameters:

• Sand yield up to 45-60%

• Fineness modulus adjustable range 2.2-3.0

• Stone powder content controllable between 7-15%

Applicable Scenarios: High-quality manufactured sand production, especially suitable for high-standard concrete sand.

6. Hammer Crusher: An Economical and Practical Efficiency Expert

Heavy Hammer Crusher

Utilizing the impact crushing principle, the rotor drives the hammers to achieve one-time crushing of materials. A grate screen ensures uniform output particle size, and the heavy-duty rotor design ensures stable operation.

Performance Characteristics:

• Crushing ratio up to 30-40

• Integrated coarse, medium, and fine crushing

• Low equipment height, simple foundation construction

Applicable Scenarios: Crushing and processing of medium to low hardness materials, with an hourly output of up to 3000 tons.

7. Roll Crusher: A Precision Control Energy Saving Pioneer

Double roller crusher

The double roll crusher achieves material compression crushing through two opposing rotating rollers. The hydraulic system provides precise pressure control and comprehensive overload protection. The roller surface can be finished with different processes such as patterning and welding.

Unique Advantages:

• Over-crushing rate less than 5%

• Significant energy saving effect, saving 30% of electricity compared to similar models

• Low dust generation

Applicable Scenarios: Fine crushing of medium-hardness materials such as coal and coke.

8. Double-Stage Hammer Crusher: An Innovator of Technological Fusion

Double-Stage Hammer Crusher

Combining the working principles of hammer crushers and impact crushers, it achieves multiple crushing effects of impact, collision, and grinding. The unique vortex crushing chamber design allows materials to form a continuous layer for crushing within the chamber.

Innovative Features:

• Screenless design, anti-clogging

• Suitable for crushing high-moisture materials

• Maintenance cycle up to 6-8 months

Applicable Scenarios: Crushing of sticky materials with a moisture content ≤8%, with an hourly output of up to 100 tons.

IV. Equipment Combination Schemes Recommendations

Fixed Production Line Scheme: A classic combination of jaw crusher + cone crusher + sand making machine, suitable for large-scale stone quarries, with stable output and low operating costs.

Mobile Crushing Station Scheme: A tire-mounted mobile station for flexible relocation, suitable for contractors operating across multiple sites.

Hybrid Layout Scheme: A combination of fixed main line and mobile branch lines, balancing efficiency and flexibility.

V. Practical Selection Recommendations

1. Define Production Needs: First, determine hard indicators such as output and product specifications.

2. Conduct Material Testing First: If possible, conduct material crushing tests.

3. Life Cycle Cost: Consider not only the purchase price but also operating costs.

4. After-Sales Service Considerations: Choose a brand with a well-established service network.

VI. Future Development Trends

With the deepening of intelligent manufacturing and green mining concepts, crushing equipment is developing towards intelligence, large-scale production, and environmental friendliness. New technologies such as remote equipment monitoring and intelligent operation and maintenance are changing traditional production models.

Choosing the right crusher requires comprehensive consideration of multiple factors. It is recommended to conduct thorough research and on-site inspections before making a decision to select the equipment solution best suited to your needs. If you have specific project requirements, please consult our professional technicians for personalized solution suggestions.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!