Symons Cone Crusher | Mining Crushing Equipment

The Symons cone crusher, with its unique spring safety system, layered crushing principle, and stable performance, demonstrates a significant advantage in processing high-hardness materials. This article will delve into the working principle and core features of the Symons cone crusher, and share how it creates value for numerous projects worldwide.

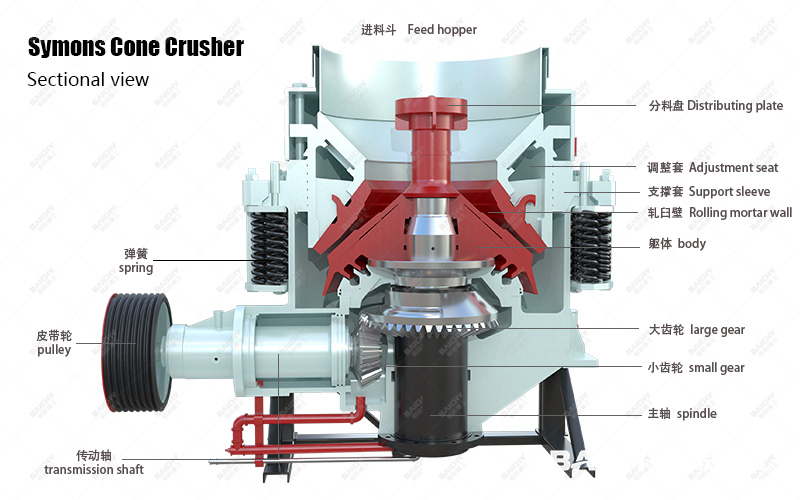

What is a Symons Cone Crusher? In-depth Analysis of its Classic Structure

The Symons cone crusher, often called a spring cone crusher, is a mechanical device that utilizes the cavity between the moving cone and the fixed cone for medium and fine crushing. Its core design has been tested over decades and is still widely used today.

Working Principle: Layered Crushing and Spring Protection

Working Principle: Layered Crushing and Spring Protection

The core of the Symons cone crusher is the layered crushing principle. The material is subjected to multiple compressions, impacts, and bending within the crushing chamber formed by the moving cone and the fixed liner, thereby achieving selective crushing, effectively reducing the content of needle-like and flaky products, and obtaining a finished product with a better particle shape.

Its signature spring safety device is the guardian of the equipment's safe operation. When uncrushable materials (such as iron blocks) enter the crushing chamber, the powerful impact compresses the spring, increasing the distance between the moving and fixed cones, allowing the foreign object to be discharged smoothly. The spring then returns to its original position, and the equipment continues normal operation. This design greatly protects core components and avoids costly downtime for maintenance.

Main Structure and Model Classification

A standard Symons cone crusher mainly consists of a frame, drive shaft, eccentric sleeve, crushing cone, adjusting device, adjusting sleeve, and spring safety device. Depending on the crushing chamber type, it is typically classified as standard (medium crushing), medium (medium-fine crushing), and short-head (fine crushing) to meet different particle size production needs.

Why Do the Significant Advantages of the Symons Cone Crusher Remain Popular?

Even with the increasing maturity of hydraulic cone crusher technology, the Symons cone crusher still maintains strong market vitality, thanks to its irreplaceable advantages.

1. Economical Operating Costs and Easy Maintenance: The structure is relatively simple, and core components such as liners are easy to replace. For budget-sensitive customers or those handling highly abrasive materials, its overall cost-effectiveness is outstanding.

2. Excellent Finished Particle Shape: The layered crushing principle ensures cubic particles with a reasonable gradation, making it particularly suitable for high-standard building aggregates and engineering projects.

3. High Reliability and Long Service Life: The robust steel structure and mature manufacturing process enable the equipment to withstand long-term harsh operating conditions, resulting in a long mean time between failures (MTBF).

4. Strong Overload Protection: The spring safety system effectively handles accidental entry of uncrushable materials, and its stability is highly praised in scenarios with low automation requirements.

The Symons cone crusher is being installed in Saudi Arabia.

Success Story: Application of Symons Cone Crusher in Actual Production

We once provided a Symons cone crusher (standard model) for secondary crushing at a large granite quarry in East China.

Customer Pain Points: The existing equipment had a high content of needle-like and flaky particles in the finished product, resulting in low market acceptance, and the equipment vibrated excessively, affecting the foundation.

Our Solution: Replace the existing equipment with a Symons cone crusher with a processing capacity of 150 tons/hour.

Results: The finished aggregate particle shape was significantly improved, with needle-like and flaky particles accounting for less than 10%, meeting the material standards for high-end commercial concrete. Simultaneously, the equipment operated smoothly with a long maintenance cycle, earning high praise from the customer. This fully demonstrates the significant value of the Symons cone crusher in enhancing product added value and reducing operating costs.

Related Equipment Recommendations: Building an Efficient Crushing Production Line

An excellent Symons cone crusher needs to work in conjunction with upstream and downstream equipment to achieve maximum efficiency. We recommend:

Primary Crushing: Pair it with a jaw crusher as the primary crushing equipment, forming a classic two-stage crushing system of jaw crusher + cone crusher.

Feeding Equipment: Use a vibrating feeder to ensure uniform and continuous feeding to the Symons cone crusher, avoiding cavity blockage and achieving full-cavity crushing.

Screening Equipment: A circular vibrating screen forms a closed-loop circulation system, screening out qualified products and returning oversized particles to the Symons cone crusher for further crushing, improving overall efficiency and yield.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a Symons cone crusher and a hydraulic cone crusher?

A1: The main difference lies in the adjustment and safety devices. The Symons cone crusher uses a spring safety mechanism and mechanical adjustment of the discharge opening; the hydraulic cone crusher uses a hydraulic system for clearing the chamber, adjustment, and overload protection, offering higher automation and more precise adjustment, but also relatively higher initial investment and maintenance costs.

Q2: How do I choose the appropriate Symons cone crusher model based on my output and discharge particle size requirements?

A2: This requires considering your maximum feed size, desired discharge particle size (e.g., 0-5mm, 5-10mm, etc.), and hourly output requirements. Generally, the standard model is used for medium crushing, and the short-head model for fine crushing. As a professional manufacturer, we offer free selection advice and solution configuration based on your specific materials and needs.

Q3: How often do the liners of a Simmons cone crusher typically need to be replaced?

A3: The lifespan of the liner depends on the abrasiveness of the material being crushed, the equipment's operating time, and routine maintenance. For moderately abrasive granite, the lifespan is typically between 500-1000 hours. It is recommended to regularly check the liner wear and adjust the discharge port promptly to ensure a stable discharge particle size.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!