200 T/H Stone Crushing Equipment Selection

In the mining equipment industry, the efficiency of a sand and gravel production line directly determines a company's competitiveness and profitability. As a marketing expert with many years of experience in the mining equipment field, I understand the pain points customers face when choosing crushing equipment: how to balance capacity, energy consumption, maintenance costs, and long-term reliability? Today, we will delve into the key technologies of 200 tons/hour stone crushing equipment, providing you with a comprehensive solution from selection to optimization.

I. Why has 200 tons/hour crushing equipment become the industry standard?

With the rapid development of infrastructure construction and the real estate industry, the market demand for sand and gravel aggregates continues to grow. A 200-ton/hour capacity design perfectly meets the needs of medium to large-scale sand and gravel production lines, ensuring efficient output while avoiding excessive equipment investment. This type of equipment is typically used for crushing hard stones such as limestone, granite, and basalt, ensuring a high crushing ratio while guaranteeing that the particle shape meets the standards for construction sand.

II. Core Equipment Selection Guide: Key Parameters and Performance Comparison

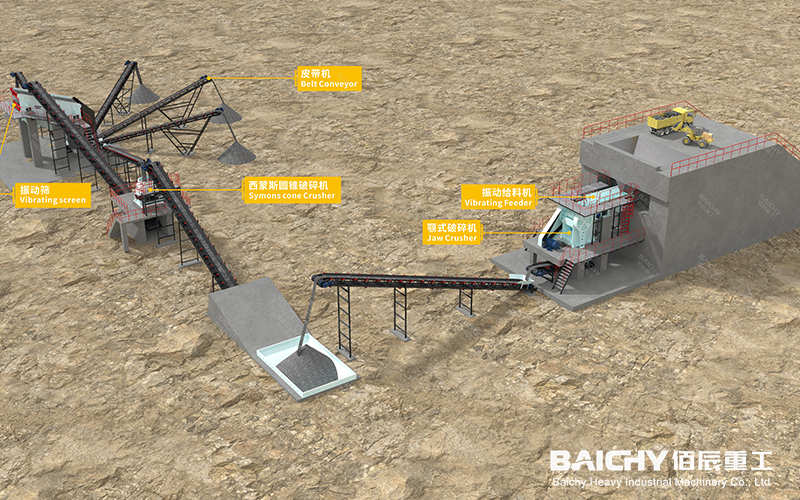

When selecting crushing equipment, it is necessary to comprehensively consider the material hardness, feed particle size, output specifications, and on-site operating conditions. We recommend jaw crushers for primary crushing, combined with cone crushers or impact crushers for medium and fine crushing, to achieve a highly efficient and energy-saving production line configuration. The following table compares the core parameters of common 200-ton/hour crushing equipment:

| Equipment Type | Maximum Feed Size (mm) | Discharge Size (mm) | Power (kW) | Applicable Materials | Advantages |

| Jaw Crusher | 1200 | 150-300 | 160-200 | High Hardness Stone | Simple Structure, Low Maintenance Cost |

| Cone Crusher | 350 | 30-60 | 220-280 | Medium to High Hardness Stone | High Crushing Efficiency, Uniform Particle Shape |

| Impact Crusher | 800 | 20-50 | 200-260 | Medium to Low Hardness Stone | Adjustable Discharge Size, Low Energy Consumption |

| Vertical Shaft Impact Crusher | 60 | 0-5 (Sand Making) | 180-240 | Sand Making of Various Stones | High Sand Making Rate, Excellent Product Particle Shape |

III. Three Strategies for Optimizing Production Line Efficiency

1. Integrated Automated Control System: Utilizing a PLC intelligent monitoring system, the system adjusts feed rate and crushing parameters in real time, reducing manual intervention and improving production stability.

2. Upgraded Wear-Resistant Materials: Utilizing high-chromium alloys or ceramic composite materials extends the lifespan of vulnerable parts and reduces downtime for replacement.

3. Environmentally Friendly and Energy-Saving Design: Equipped with dust removal and noise reduction devices, meeting green mining standards, and optimizing the power transmission structure to reduce energy consumption by over 15%.

IV. Marketing Perspective: How to Create Extra Value for Customers?

As an equipment supplier, we not only provide high-performance products but also focus on after-sales service. For example, providing customers with free production line planning, regular maintenance training, and rapid spare parts supply can extend equipment lifespan by over 20%. Demonstrating real-world case studies (such as comparative data showing a 30% increase in production capacity in a mining project) enhances customer trust and promotes long-term cooperation.

The 200-ton/hour stone crushing equipment is the core of a sand and gravel production line, and its selection and optimization directly impact the overall return on investment. We are committed to helping customers build an efficient, low-carbon, and sustainable mining production system through technological innovation and attentive service. If you are planning or upgrading your production line, please feel free to contact us for customized solutions!

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.