In mineral processing, the moisture content of materials directly affects transportation costs, subsequent beneficiation efficiency, and the quality of the final product. A high-efficiency, reliable mining dryer is key to solving this problem. This article will guide you through an in-depth understanding of the working principle, significant advantages, and outstanding performance of this mineral drying equipment in various scenarios.

I. What is a Mining Dryer? What is its Working Principle?

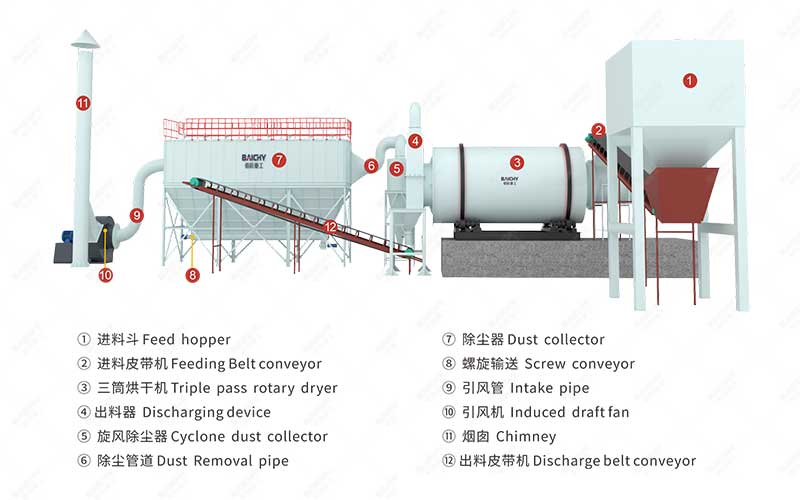

A mining dryer, especially the mainstream rotary drum dryer, is a heavy-duty piece of equipment that removes moisture from mineral raw materials in batches through heat exchange. It typically consists of a large, slightly tilted, slowly rotating steel drum.

Its working principle can be simply summarized as follows:

1. Feeding and Crushing: Wet material is fed into the drum by a feeder and continuously collides and is lifted by the lifting plates inside the drum to increase its contact area with hot air.

2. Hot Air Contact: High-temperature hot air (from a coal-fired, gas-fired, or biomass-fueled hot air furnace) comes into full contact with the lifted material, rapidly evaporating the moisture.

3. Drying and Conveying: Under the rotation and tilting action of the drum, the material is slowly pushed towards the discharge port while drying.

4. Dust Removal and Dehumidification: Exhaust gas containing water vapor is purified by a dust removal system (such as a cyclone dust collector or bag filter) before being discharged, and the dried finished material is collected.

This design ensures the continuity, high efficiency, and low energy consumption of the drying process.

II. Why Choose Our Mining Dryer? Four Core Advantages

Faced with harsh working conditions of high humidity and high abrasion, ordinary drying equipment is often inadequate. Our heavy-duty mining dryer is designed for these challenges and possesses the following unparalleled advantages:

• 1. High Efficiency and Energy Saving, Reducing Operating Costs:

◦ Utilizing innovative heat exchange technology and high-quality insulation materials, it maximizes the utilization of heat energy, effectively reducing fuel consumption and directly saving customers operating costs.

• 2. Robust and Durable, Unaffected by Harsh Environments:

◦ The rollers and lifting plates are made of special wear-resistant manganese steel, resistant to corrosion and wear, extending the equipment's lifespan far beyond industry standards, greatly reducing maintenance needs and downtime.

• 3. Large Processing Capacity, Adaptable to perse Materials:

◦ From viscous coal slime and fine mineral powder to industrial sludge and various types of slag, our equipment can stably process them, meeting the continuous production needs of large-scale mines.

• 4. Intelligent Temperature Control, Uniform Drying Effect:

◦ Equipped with an intelligent temperature control system, it can precisely adjust the temperature according to the characteristics of different materials, ensuring uniform moisture content and stable quality in the finished product.

III. Main Application Areas: Beyond Traditional Mines

Our large-scale dryers are widely used in:

• Coal Industry: Drying of coal and coal slime.

• Metal Mines: Drying of iron concentrate, copper concentrate, lead-zinc ore powder, etc.

• Building Materials Industry: Drying of clay, limestone, slag powder, etc.

• Environmental Protection: Harmless and reduced-volume treatment of industrial and municipal sludge.

IV. How to Choose a Suitable Mining Dryer Manufacturer?

Choosing a reliable dryer manufacturer is crucial. You need to pay attention to the following points:

• Technical Strength: Does the manufacturer have independent R&D and customized production capabilities?

• Case Experience: Do they have successful cases of processing similar materials?

• After-sales Service: Can they provide comprehensive installation, commissioning, training, and after-sales support?

As a professional manufacturer of mining drying equipment, Baichy is committed to providing every customer with a complete drying solution, from site survey, scheme design, equipment customization to installation and commissioning. We deeply understand that a good machine is the cornerstone of your value creation.

Contact us now for a free technical solution and exclusive quote! Let our professional team solve your mineral drying problems and jointly achieve the goal of cost reduction and efficiency improvement.